Cauchari lithium project a high-grade lithium project located in Puna region, Jujuy Province, Argentina. The joint venture of Advantage Lithium (75%) and Orocobre (25%) is developing the project.

Preliminary economic assessment (PEA) of the project was completed in August 2018, while definitive feasibility study (DFS) is expected to be completed in the first half of 2019. Lithium production is planned to be started in 2021 and ramped up over three years.

Estimated to involve an initial capital cost of $401m, the project is expected to produce 20,000tpa of lithium carbonate (Li2CO3) through its mine life of 25 years.

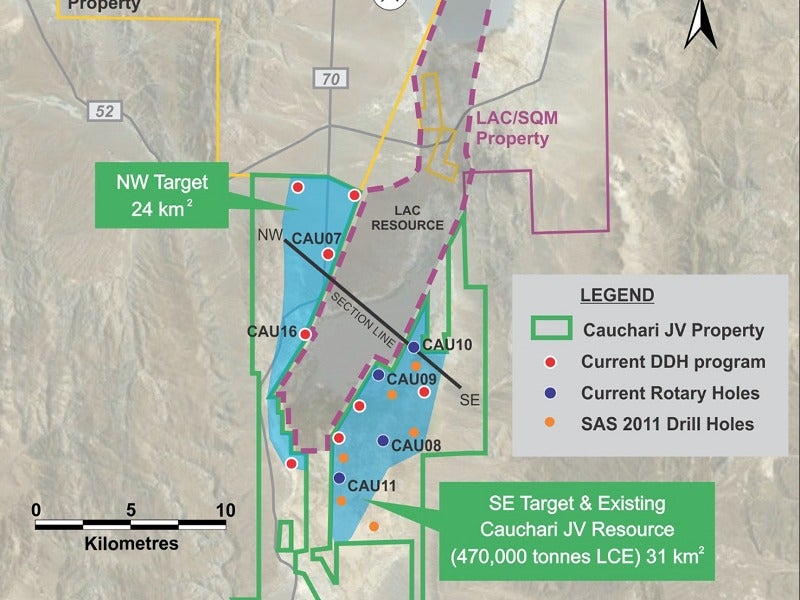

Cauchari lithium project location, geology, and mineralization

The Cauchari lithium project is located at an altitude of 3,900 meters above sea level (masl) and approximately 230km from San Salvador de Jujuy, in Jujuy Province.

The project lies in the Cauchari salar region within the Puna Plateau, which comprises the puna turbidite basement and the ordovician puna volcanics rock type. The salar is located beneath 50m-thick fine grained (clay) sediments.

The salar sediments are estimated to be at least 400m-450m deep.

Cauchari lithium project reserves

The Cauchari lithium project is expected to contain inferred resources of approximately 3.02 million tons (Mt) of lithium carbonate equivalent (LCE) and 9.5Mt of potash (KCl).

Mining and ore processing at Cauchari lithium project

Conventional brine mining method will be used at Cauchari lithium project, which will feature two production wellfields with individual pumping rate between 10l/s and 25l/s.

Brine form the production wellfields will be pumped to the first stage evaporation ponds, which employ solar evaporation process to crystallize halite, glauber, glaserite, silvite, and borate salts.

Slaked lime will be added to the brine to recover magnesium hydroxide and calcium as gypsum. The brine will be circulated in several stages to obtain a Li concentrate of 6% and forwarded to the lithium carbonate plant for further processing.

At the processing plant, the Li2CO3 concentrate will undergo precipitation to remove the remaining magnesium an calcium. The precipitated product will be filtered and re-pulped with mother liquor and deposited in the sludge ponds. Low-impurity brine will be pumped to the ionic exchange (IX) stage to remove the final remains of diand tri-valent metals.

Soda ash will be added to the purified brine to form a precipitated lithium carbonate, in the carbonation stage. It will then be separated from the solution through a belt filter and the solids fed to the drying stage.

Technical and battery-grade lithium carbonate product will be taken to Antofagasta, Chile, for shipping to customers.

Infrastructure facilities at Cauchari

Cauchari project can be accessed either from Jujuy or Salta. The project will make use of the existing infrastructure at the nearby Orocobre processing facility.

Workers will be accommodated at a camp located onsite.

Contractors involved

FloSolutions prepared the NI43-101 technical report on the resource upgrade of the project, while Andina Perforaciones drilled five test production wells.

Worley Parsons prepared the PEA for the project, while Goldman Sachs & Co was appointed as the financial advisor for the project.