The Dumont nickel-cobalt project is located in the municipalities of Launay and Trecesson in western Antibi, Quebec, Canada. Dumont Joint Venture, a joint venture (JV) between Royal Nickel Corporation and Arpent, is the project developer.

The nickel-sulphide (NiS) deposit holds the world’s second biggest nickel reserves and is also the ninth biggest project in terms of cobalt reserves. It is expected to be one of the top five biggest nickel sulphide projects in the world, following the start of production.

Feasibility study of the Dumont nickel-cobalt project was updated in May 2019. The project is expected to produce approximately 1.2 million tons (2.6 billion pounds) of nickel concentrate over a 30-year mine life. It is estimated to require an initial capital expenditure of $1bn.

Dumont nickel-cobalt project location and geology

The Dumont Nickel-Cobalt project site is located approximately 25km west of the city of Amos, Quebec. The property consists of 233 contiguous mineral claims extending in more than 9,306ha.

The property is covered by a layer of glacial overburden and muskeg, with majority of the mineralization cropping at approximately 30m below the surface.

The Dumont sill is made up of lavas belonging to the Barraute volcanic complex and volcaniclastic rocks assigned to the Amos Group. The host rocks are identified as iron-rich, tholeiitic basaltic lavas, while some intermediate rocks are believed to have occurred at the eastern end of the sill.

Dumont nickel-cobalt project reserves

The proven and probable ore reserves at Dumont project, as of May 2019, were estimated at 1.03 billion tons of ore, graded at 0.27% nickel and 107ppm cobalt. The mine is estimated to contain 6.1 billion pounds of nickel and 243 million pounds (Mlbs) of cobalt.

Mining and ore processing at Dumont nickel-cobalt project

The Dumont nickel-cobalt project proposes to use conventional open-pit mining method, involving drilling and blasting. The project proposes to remove approximately 42Mt of overburden and excavate more than 2.1 billion tons of material through its mine life.

A combination of hydraulic excavators and electric rope shovels into haul trucks will be used for ore loading.

The open-pit mining is anticipated to be ceased in year 24, following which approximately 398Mt of the low-grade ore and recovery material will support production for a period of six years.

The processing plant is being constructed in two phases, with the phase one anticipated to operate with an initial average throughput of 52,500 tons per day (tpd) and produce a nickel concentrate, which also contains cobalt and PGEs. The phase two is expected to double the throughput to 105,000tpd in the seventh year of production.

The first phase is expected to produce 33,000 tons per annum (tpa) of nickel and 1,000tpa of cobalt, while the second phase is anticipated to increase the production to 51,000tpa of nickel and 2,000tpa of cobalt.

Run-of-mine and stockpiled ore will be processed in a conventional milling process involving a primary gyratory crusher, a semi-autogenous grinder (SAG), and two ball mills.

The crushed ore will then undergo desliming process in a hydro-cyclone circuit and pass through a nickel flotation circuit. The resultant product will undergo magnetic separation to produce nickel concentrate and sulphides.

The nickel concentrate will be thickened, filtered, and stockpiled on-site before being delivered to the market either by trucks or by rail.

Infrastructure facilities

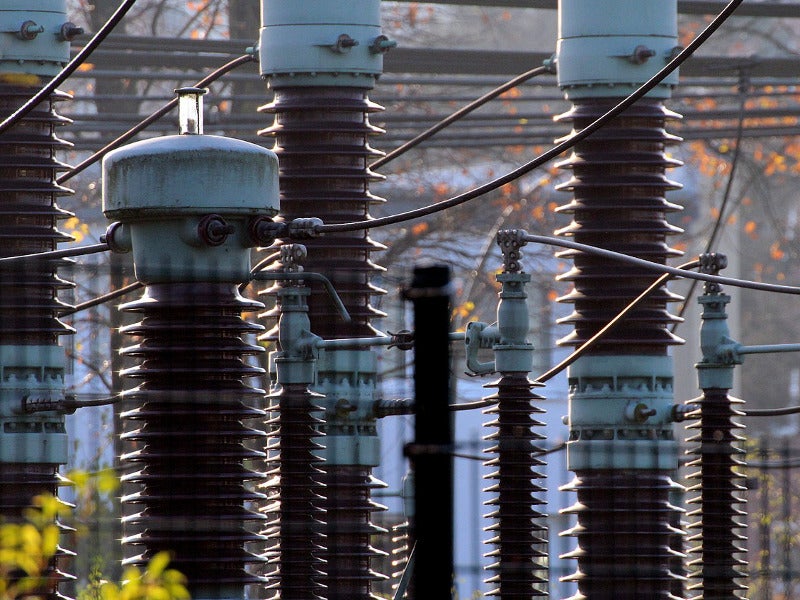

Power supply to the mine is proposed to be provided by Hydro Quebec (HQ) through a 10.5km 120kV new overhead transmission line. The project will also include the construction of a new 120kV substation and six main transformers, which will be installed near the SAG mill feed conveyor.

The tailings storage facility, located approximately 400m from the processing plant, is expected to store 680Mt of tailings in two cells.

Surface water storage at the Southeast Reservoir and local groundwater wells will be the initial source of water supply for Dumont. Operational water will be collected by recycling water from the TSF, while Southeast Reservoir will provide the make-up and fresh water.

Contractors involved

Ausenco Engineering Canada updated the feasibility study (FS) report of the Dumont nickel-cobalt project, under a contract awarded in September 2018. Ausenco was supported by various consultants including Ausenco Services, SRK Consulting (Canada), Snowden Mining Industry Consultants, Wood, Norascon, Golder Associates, and WSP Global.

In addition to participating in the FS, Norascon is also responsible for the pre-stripping, establishment of mining areas, and permitting activities of the Dumont nickel-cobalt project.