The Bridgeport Harbor Station 5 (BHS 5) is a 485MW combined-cycle power plant developed to replace the coal-fired unit three at the Bridgeport Harbor Station in Atlantic Street, Connecticut, US.

PSEG Power Connecticut, a subsidiary of PSEG Power, owns and operates the plant. The announcement to construct the unit five was made in February 2016.

The construction was started in June 2017 and the unit was commissioned in June 2019 with a total investment of $550m (approximately £380m). It created approximately 350 jobs during the construction.

The new unit project replaces the five decades-old unit 3 at the plant. It is expected to provide reliable and clean energy for approximately 500,000 homes in Connecticut.

Background

PSEG entered a Community Environmental Benefits Agreement (CEBA) with the City of Bridgeport, under which PSEG agreed to retire the unit three of BHS and replace it with a new plant with more efficient technology.

Since its establishment in 2002, the Bridgeport Harbor Station controlled emission of mercury and particulate matter by roughly 95%. It also minimised the SOx and NOx emission levels by 76% and 67%, respectively.

Bridgeport Harbor Station 5 combined-cycle plant make-up

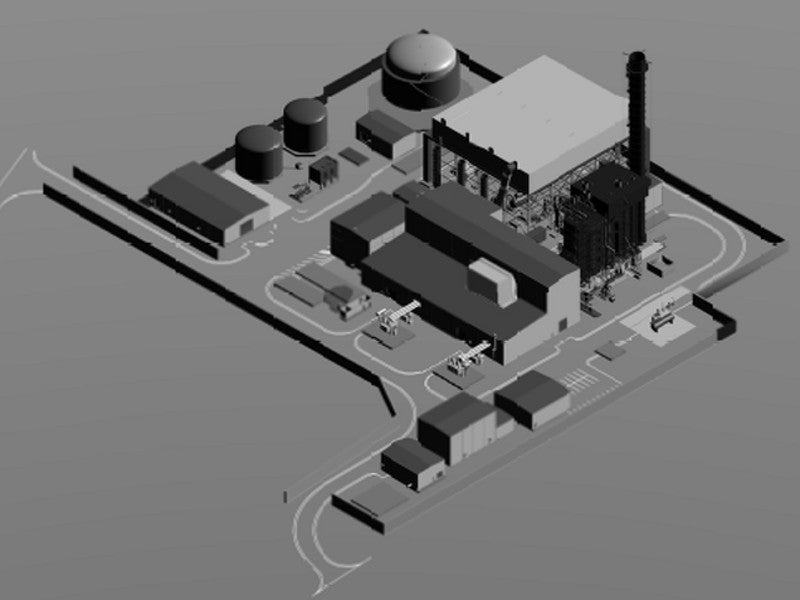

The Bridgeport Harbor Station 5 combined-cycle power plant is installed with a GE 7HA.02 gas turbine coupled with a steam turbine unit. The main components of the plant include a gas turbine, a heat recovery steam generator (HRSG), a steam turbine, associated generators, and balance-of-plant equipment.

Natural gas is used as the primary fuel to generate electricity, while ultra-low sulphur diesel (ULSD) is used as back-up fuel. Heat from the combustion turbine is diverted to the HRSG to produce steam for generating additional power.

Infrastructure

The new combined-cycle project will use the existing infrastructure facilities of PSEG’s Bridgeport Harbor Station. Four storage tanks within the site were dismantled to accommodate the new plant.

Primary infrastructure at the new unit includes turbine building, HRSG unit, a flue exhaust stack, air-cooled condenser, boiler, control room, demineralised water handling and storage facility, and storage space for hydrogen and ammonia.

Support infrastructure facilities include warehouse, maintenance shop, service/fire water pumps, emissions monitoring building, emergency diesel generator, and an auxiliary electrical building.

Transmission of power from Bridgeport Harbor Station unit five

The power generated by the BHS unit three is transferred to the Pequonnock substation by using 115kV transmission lines.

A new gas-insulated substation was constructed for the new power plant. Eight existing 115kV transmission and associated distribution lines feeding the existing Pequonnock substation were relocated to connect to the new substation.

The new GIS substation is located on approximately two acres of vacant land inside the existing PSEG BHS site and contains 115kV components such as circuit breakers, switches, and bus.

Contractors involved

GE was awarded the equipment supply contract for the unit five of the Bridgeport Harbor Station in April 2016. The contractual scope includes the supply of gas and steam turbine units and an Alstom-engineered HRSG unit.

PSEG Power Connecticut awarded a $22m-worth engineering and procurement support contract to SNC-Lavalin for the project, in May 2017.

Shelby Mechanical performed mechanical works for the Bridgeport Harbor Stations unit five.