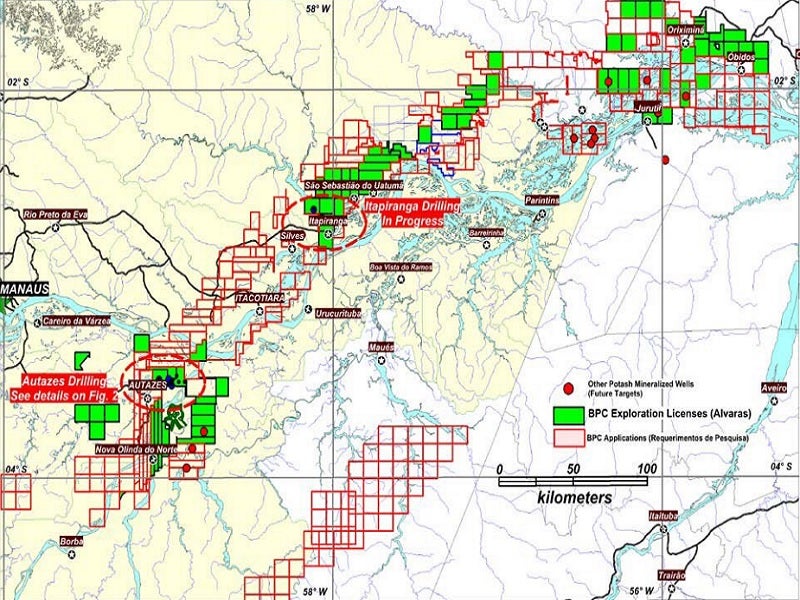

Autazes potash project is located in Brazil’s Amazonas state, approximately 30km away from the city of Autazes. It is being developed by Brazil Potash (Potassio do Brasil), a fertiliser company.

Brazil Potash plans to produce 2.4 million tonnes per annum (Mtpa) of granular potash, which will supply approximately 25% of the company’s needs. The mine will employ 1,180 employees initially, primarily from Autazes.

Brazil is an agriculture-based economy, which consumes approximately 8.9Mtpa of potash for its needs with an annual increase of 3.5% in demand. The country depends on potash imports mainly from Canada and Russia to meet 94% of its fertilizer demand.

The Autazes potash project and the surrounding Amazonas region together are the world’s third-largest potassium reserve, after Canada and Russia. It is expected to help Brazil avoid importing potash thereby providing huge cost savings for the country.

Autazes potash project controversy

The potassium deposits are based on the indigenous lands and hence required permission from the landowners to drill or mine in the area. Brazil Potash started drilling operations in 2013 in secret, inviting controversy and opposition from the landowners.

The conflict was followed by legal battle where 12,000 people of Mura Indian ethnicity filed litigation concerning the social and environmental repercussions of mining in the region.

The decision on the development is pending and has stalled the construction of the project.

Autazes mine location and geology

The project is located 120km south-east of Manaus, a city near to Autazes. The deforested area around the mine is also used for cattle farming. Brazil Potash holds claims over an area of 17,650km2 within the Amazon potash basin.

The region is filled with Paleozoic rocks deposited on a substrate and Precambrian rocks found in the north and south region of the Amazon basin. The Amazon basin is grouped and compartmentalised into tectonostratigraphic domains and geochronological provinces.

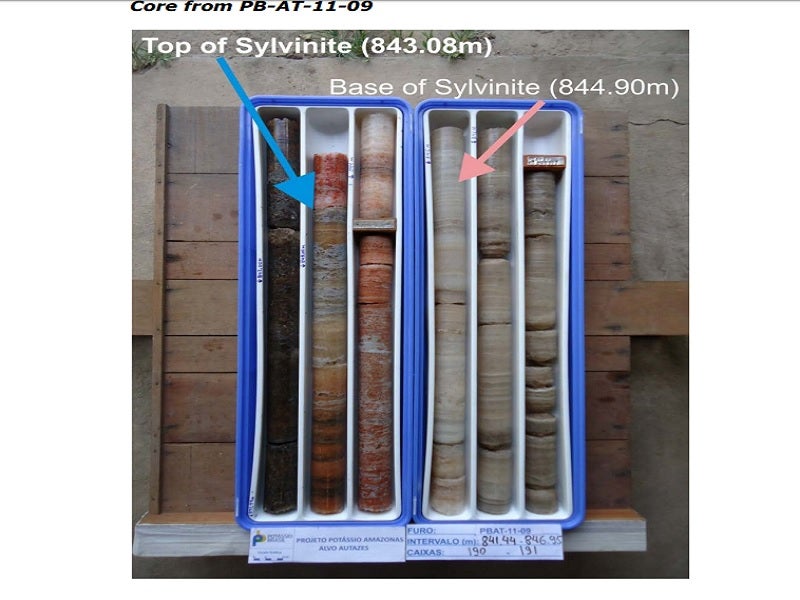

Autazes potash project mineralisation

Potash mineralisation covers an area of 155km², with an average thickness of 2.07m and lies between the depths of 685m and 865m.

The mineralised horizon is subdivided from the bottom to the top into Lower Mineralised Range, with predominance of white, thin and laminated sylvites; Intermediate Mineralised Range, comprising brown silvinite and disseminated sulfates; Upper Mineralised Range, consisting of reddish silvinites with coarse granulation.

The distributions of potassium chloride content and mineralisation thickness are related to the distinctive characteristics of these units throughout the deposit.

Autazes potash project reserves

The Autazes mine has 87Mt of proven potash reserves at a grade of 28.7% containing 25Mt of potassium chloride (KCl).

The probable reserves of the mine stand at 161Mt at a grade of 27.9% containing 45Mt of KCl. The mine contains measured reserves of 151Mt at a grade of 31.2% containing 47Mt of KCl.

The indicated and inferred reserves are estimated at 480Mt at a grade of 60.2% containing 145Mt of KCl.

Autazes mine development and infrastructure details

The relatively shallow depth of the mine allows easy drilling and mining. The mine is planned to be developed using underground room and pillar mining methods. The tailings produced will be back filled into the underground workings. A ramp-up period of three years is expected to be required to reach full production level.

The mine will have an industrial complex for potash extraction and treatment using hot leach process. The treatment plant will include primary crushing, wet process, dry process, and waste and reagent management. It will have a nominal processing capacity of 8.5Mtpa of ore to produce 2.44Mtpa of granulated potash concentrate with 95% KCl. The processing plant will be equipped with two processing lines with a capacity of 558t/h of ore.

A 165km-long, 230kV transmission line to provide power to the project from the national grid will be constructed. The transmission line is also expected to benefit 100,000 locals who are currently dependent on diesel-generated power.

Product handling and transportation

The location of the mine allows easy access to highways and river system of the Amazon River and its tributary, the Madeira river, which will provide logistic benefits and save costs up to $80 per tonne. The proximity of mine to the river will also result in the reduction of green house gas emissions of close to 508ktpa CO2 equivalent.

The granulated product produced at the mine will be transported to the port of Urucurituba by trucks. It will then be transported by barges to consumers in the region. Up to 20 barges with a capacity of 2,000t of cargo each are planned to be used.

Contractors involved

Worley Parsons completed the bankable feasibility study for the project, while Ercosplan performed the metallurgical and geotechnical tests for the mine.

CITIC Construction, a subsidiary of CITIC Group, signed a contract with Brazil Potash in November 2019 to carry out engineering, procurement, and construction works for the mine.