The Darlington Nuclear Generating Station, Canada’s second-biggest nuclear power station located in Ontario, is undergoing a multibillion-dollar refurbishment project to extend the operational life of the facility by 30 years.

Owned and operated by Ontario Power Generation (OPG), the 3.5GW facility comprises four reactor units commissioned between 1990 and 1993. The Darlington nuclear power station is capable of generating 31 million MWh of electricity to power approximately 2.5 households a year, accounting for approximately one-fifth of Ontario’s total annual electricity demand.

Ontario Power Generation (OPG) secured approval to refurbish each of the reactor units at the site with a total estimated investment of approximately £10bn ($12.8bn) in 2016.

The refurbishment of the second reactor unit (Unit-2) of the plant was started in 2016 and completed in March 2020. The remaining three units are expected to be refurbished and restarted for the stable supply of clean electricity by 2026.

Although the refurbishment of the plant’s Unit-3 was originally scheduled to be started in May 2020, it has been temporarily delayed due to the COVID-19 pandemic.

Location and site details

The Darlington nuclear power station is located on a 480ha-site on the north shore of Lake Ontario near the town of Clarington, in the Durham region of southern Ontario, approximately 72km east of Toronto.

Darlington nuclear power station refurbishment details

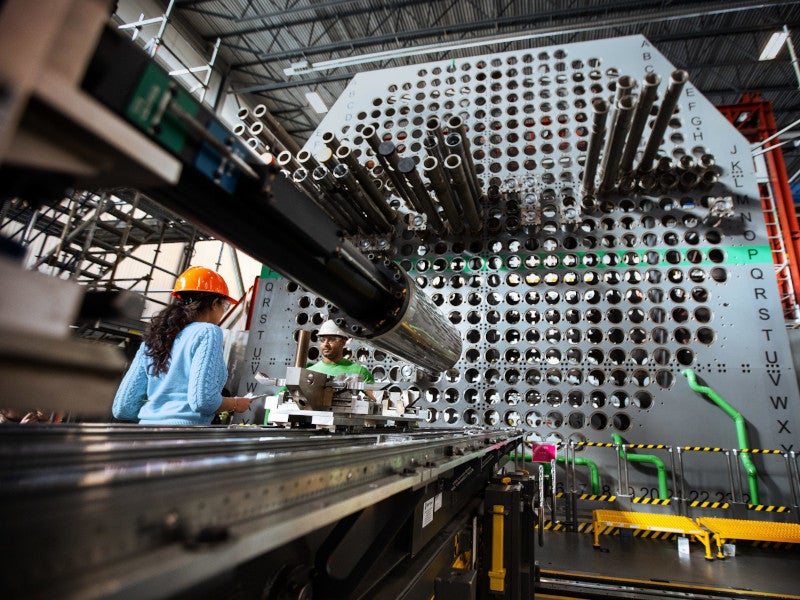

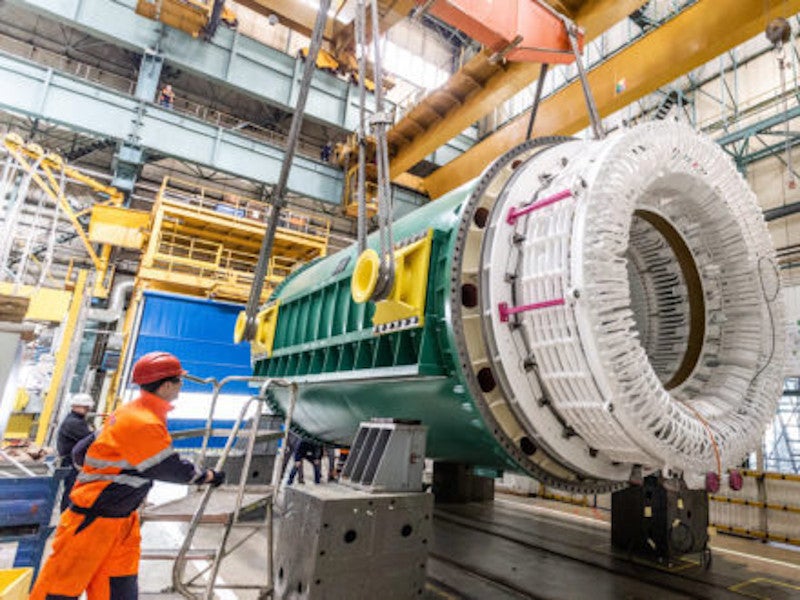

The refurbishment project involves the replacement of fuel channels, calandria tubes, feeder pipes, and end fittings of each reactor core, as well as the associated steam generators, turbine generators, fuel handling systems, and other ancillary plant equipment on a sequential basis.

The refurbishment of each generating unit at the site is expected to take approximately three years. Unit-2 was the first unit to be refurbished. The refurbishment of the Unit-3 is planned to be carried out between 2020 and 2024, the Unit-1 between 2022 and 2025, and the Unit-4 between 2023 and 2026.

Each unit will be taken out of service to facilitate the refurbishment works. The Darlington nuclear plant refurbishment project is intended to extend the operational life of the facility until 2055.

Darlington nuclear power plant make-up

The Darlington nuclear generating station comprises four Canada Deuterium Uranium (CANDU) pressurised heavy-water reactor (PHWR) units of 881MW capacity each. Unit two of the plant was commissioned in 1990, while unit one was brought into operation in 1992, and units three and four were commissioned in 1993.

Each reactor comprising 480 fuel channels is placed within a reactor building made up of 1.8m-thick heavily reinforced concrete. The reactor buildings are connected to a 71m-high cylindrical vacuum building by a pressure relief duct.

The reactor units share a common turbine hall that measures 580m-long, 137m-wide, and 45m-high. The power station also houses two water-filled storage bays for storing the used fuel.

Contractors involved with the Darlington nuclear power station refurbishment

SNC-Lavalin, in a 50:50 joint venture partnership with Aecon Group, was awarded a £1.9bn ($2.75bn) contract to execute the re-tubing and feeder replacement (RFR) works for the Darlington nuclear reactors in January 2016.

The same joint venture was also engaged for the definition phase of the refurbishment project between 2012 and 2016.

Candu Energy, a wholly-owned subsidiary of SNC-Lavalin, was awarded a contract to provide nuclear engineering services for the Darlington nuclear power station for a period of five years in April 2020.

US-based engineering and construction company Fluor was contracted to replace the emergency power generators for Units 1 and 2 of the Darlington nuclear power station in December 2017.

Black and McDonald was engaged for the inspection, overhaul, maintenance, and replacement of valves, as well as for heat exchangers and a piping modification works for the refurbishment project.

BWXT Canada was subcontracted by the SNC-Lavalin / Aecon joint venture (JV) to manufacture and supply the feeders for Units 1, 3, and 4 reactors as part of the Darlington nuclear power station refurbishment project in April 2017.

BWXT Nuclear Energy Canada was also awarded a five-year contract extension to manufacture and supply fuel for the Darlington nuclear power station in March 2018.

E.S. Fox was contracted to fabricate thermal insulation cabinets for the Darlington refurbishment project.

Other consultants and contractors engaged in the refurbishment project include M.G. Burke Consulting, Babcock & Wilcox, NA Engineering, Intech, AMEC, Faithful & Gould, Worley Parsons, Tetra Tech, RCM Technologies, and Algal Engineering.