The Kerr-Sulphurets-Mitchell (KSM) project located in northern British Columbia, Canada is one of the world’s biggest undeveloped copper-gold deposits. Seabridge Gold is developing the project through its subsidiary, KSM Mining.

The project development plan has undergone multiple changes since the first preliminary feasibility study (PFS) was released in March 2010. The environmental impact assessment (EIA) for the project was completed and approved by the provincial and federal governments in July 2014, while the latest PFS was released in April 2020.

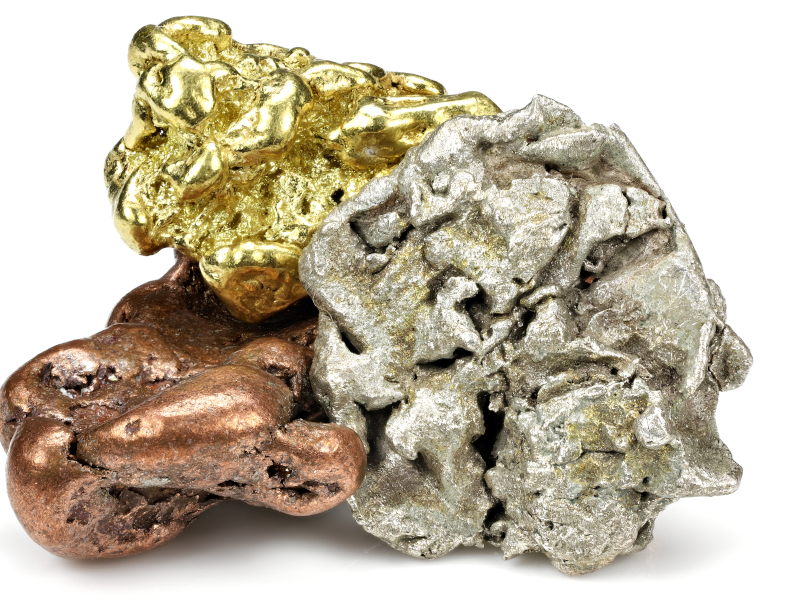

Utilising a combination of open-pit and underground mining methods at four mineral deposits at an average milling rate of 170,000 tonnes per day (tpd), the KSM mine is expected to produce 27.6 million ounces (Moz) of gold and 17 billion pounds (Blbs) of copper over an estimated mine life of 44 years.

The four mineral deposits planned to be developed as part of the project are Mitchell, Kerr, Sulphurets, and Iron Cap that also contain a significant amount of silver and molybdenum mineralisation.

The initial investment for the KSM mining project is estimated to be approximately £4.1bn ($5.1bn)

KSM property development history

The KSM property has an exploration history dating back to the 1960s with the involvement of miners including Newmont Mining, Granduc, Phelps Dodge, and the Meridian Syndicate showing.

Esso Minerals began exploration drilling at the Sulphurets zone back in 1969 while exploration at Iron Cap mineralized zone began in 1980 by Esso Minerals. The exploration drillings at Kerr zone followed in 1985 under Brinco Ltk and at Mitchell Creek by Newhawk in 1991.

Placer Dome acquired a 100% interest of the Kerr deposit from Western Canadian Mines in 1989. The adjacent Sulphurets property which also hosts the Mitchell Creek deposit was acquired from Newhawk the following year in 1990.

Seabridge Gold acquitted full ownership of the Kerr and Sulphurets Zones from Placer Dome in 2000.

Project location, geology, and mineralisation

The KSM copper-gold deposit is located along the coastal mountains in north-western British Columbia, approximately 950km north-west of Vancouver and 21km south-southeast of the former Eskay Creek Mine.

The Property lies within the Stikinia volcanic island-arc terrane accreted onto the Paleozoic basement of the North American continental margin in the middle Jurassic.

The Stikina terrane is predominantly abundant with early Jurassic sub-volcanic intrusive complexes and several precious and base-metal-rich hydrothermal systems.

The Kerr deposit is centred on a north-south trending, steep westerly dipping tabular intrusive complex of early Jurassic. Mineralisation occurs over a strike length of 2,400m, with the width and the vertical depth measuring up to 800m and 2,200m respectively.

The Sulphurets deposit has numerous east-vergent faults intersections associated with mid-Cretaceous Skeena fold and thrust belt. The main body of mineralisation is lensodial in geometry with a north-west dip of approximately 30 degrees. The strike length is 2200m, while the thickness of mineralisation is 330m.

The Mitchell zone is underlain by foliated, schistose, intrusive, volcanic, and clastic rocks with mineralisation related to early Jurassic Mitchell intrusive complex. The complex is composed of Sulphurets (Texas Creek) suite diorite, monzodiorite, and granodiorite stocks and dykes.

The Iron Cap deposit occurs structurally above the Mitchell deposit. The mineralised zone is a tabular body with a north-south strike of 1,500m and a down dip of 1,500m with up to 800m in thickness.

Reserves at the KSM project

The KSM mine is estimated to hold approximately 2.2 billion tonnes of proven and probable reserves grading 0.55g/t gold, 0.21% copper, and 2.6g/t silver.

Mining methods for the KSM Project

The KSM Project will utilise a combination of conventional open-pit mining and underground block cave mining methods.

Open-pit mining will be implemented at Mitchell, Sulphurets, and Kerr deposits while underground operations will be carried out at Iron Cap and Deep Kerr.

The majority of the ore will be derived from the open-pits during the initial 33 years of the mine life at an average rate of 170000tpd. The production rate will be reduced to 120000tpd from year 34.

Ore processing

The proposed KSM processing plant located approximately 23km north-east of the mine site at Treaty Ore Preparation Complex (OPC) will have an average processing capacity of 170000tpd.

Primary crushing facilities for the open-pit mines will be located at Mitchell while the underground mines will have underground primary crushing facilities. Secondary crushing will be done by cone crushers and tertiary crushing will be done using high pressure grinding rolls (HPGR).

Primary grinding circuits will feed the copper-gold rougher/scavenger flotation circuit to produce copper rougher flotation concentrates. The concentrates will be reground in two tower mills and upgraded in a three-stage cleaner flotation circuit to produce a copper-gold concentrate.

The copper-gold concentrate will be thickened in a 21m-diameter high rate thickener to produce thickener underflows which will undergo concentrate pressure filtering to reduce water content. This copper-gold concentrate will be stockpiled before transportation to the port at Stewart, British Columbia, for export.

The copper rougher concentrate will also be used to produce a gold-bearing pyrite concentrate via pyrite flotation. The pyrite concentrate will be thickened and passed to a cyanide leaching circuit and an elution circuit for gold recovery. Pregnant solution from the elution circuit will undergo electrowinning to produce metal sludge. The metal sludge will be filtered, dried, and smelted in an induction furnace to produce gold and silver dore.

Project infrastructure

The KSM project is currently accessible via helicopter which will facilitate road construction and construction camps. The operations camp will be installed between Sulphurets and Gringas creeks and will consist of a helipad, sleeping dorms, sewage treatment, and other associated structures.

Electrical power will be supplied via a 287kV British Columbia Hyrdo transmission line from a substation near Bob Quinn Lake, north of the KSM mine site. The project site will be connected to the line at new Treat Creek Terminal which lies adjacent to Highway-37 approximately 18km south of Bell II.

Potable water for the processing plant will be supplied from nearby wells to a storage tank. Water required for the underground development and drilling will be supplied through the Iron Cap access tunnel via pumps in the Mitchell Valley.

Underground power supply will be provided from the Mitchell area substation FLT2 via two redundant 25kV cables.

Contractors involved

The 2020 preliminary economic assessment (PEA) report for the project 2020 was prepared by Tetra Tech in collaboration with Moose Mountain Technical Services, Golder Associates, BGC Engineering, Resource Modelling Inc., McElhanney Consulting Services, Klohn Crippen Berger, ERM Consultants Canada WN Brazier Associates, and Wood Canada.