The Kharmagtai Copper-Gold Project is a copper-gold mine being developed located in the South Gobi region of Mongolia.

The mine is being developed by joint venture partners- Mongolia-based mining company Xanadu Mines and China-headquartered Zijin Mining Group.

Both the companies signed a strategic partnership agreement in April 2022. Under the deal, Zijin agreed to invest in Xanadu and Kharmagtai.

In April 2022, Xanadu Mines completed a scoping study of the Kharmagtai copper-gold project. It indicated the potentiality of Kharmagtai as a low cost, long life copper-gold mine with a life of 30-year life.

The mine is expected to produce 50 kilo tonnes per annum (ktpa) copper and 110kozpa gold annually over the Life of Mine (LOM).

An amended Preliminary Economic Assessment (PEA) of the copper-gold project was published in May 2024.

A pre-feasibility study on the project commenced in 2023. It is expected to be completed in the third quarter of 2024.

Early construction on the mining project is expected to begin in 2025, with pre-stripping and ore mining may begin in 2027.

Initial capital cost is estimated to be $694m, excluding expansion and sustaining capital.

Kharmagtai Project Location and Site Details

The Kharmagtai Copper-Gold Project is located in Omnogovi Province of southern Mongolia, 420km southeast of Mongolian capital of Ulaanbaatar. The site lies around northwest of the Oyu Tolgoi Copper-Gold Deposit.

Overall, the project covers an area of approximately 66.5km2. The mining licence was granted in 2013 and it is valid for 30 years.

The mine is accessible via sealed roads from the capital to Tsogt Ovoo and from there to Kharmagtai via 60km of unsealed roads.

The industrial city of Sainshand lies approximately 350km towards the east of the site.

Exploration History

In the Kharmagtai district, multiple geological surveys and mineral exploration programmes were conducted between 1960 and 1975.

The Japan International Cooperation Agency (JICA) and Metal Mining Agency of Japan (MMAJ) conducted airborne magnetic, radiometric surveys, and re-identified Kharmagtai as a porphyry-related alteration and mineralisation between 1991 and 1995.

In 1998, QGX (previously Quincunx) conducted regional geological mapping, geochemistry, geophysics, and diamond drilling of five shallow and 19 shallow shadow holes.

Between 2001 and 2006, Ivanhoe Mines Mongolia (IMMI) completed various drilling, surveys, and estimated a historical combined resource estimate of Stockwork Hill, Copper Hill, and White Hill to be 174Mt at 0.50% copper equivalent (CuEq).

Asia Gold, a subsidiary of IMMI, completed deep diamond drilling, conducted a detailed 3D Induced Polarisation (IP) survey and drilled 19 diamond holes. Asia Gold conducted these works between 2007 and 2012.

Kharmagtai Project Geology and Mineralisation

The Kharmagtai Project consists of co-genetic copper-gold porphyry centres and tourmaline breccia pipes hosted within the Carboniferous Kharmagtai Igneous Complex.

The complex consists of multiple intrusive bodies ranging between diorite, monzodiorite, quartz-monzodiorite, monzonite, and granodiorite compositions.

The mine includes three mineralisation types- porphyry style stockwork copper-gold, tourmaline breccia style and epithermal gold associated with carbonate base metal veins.

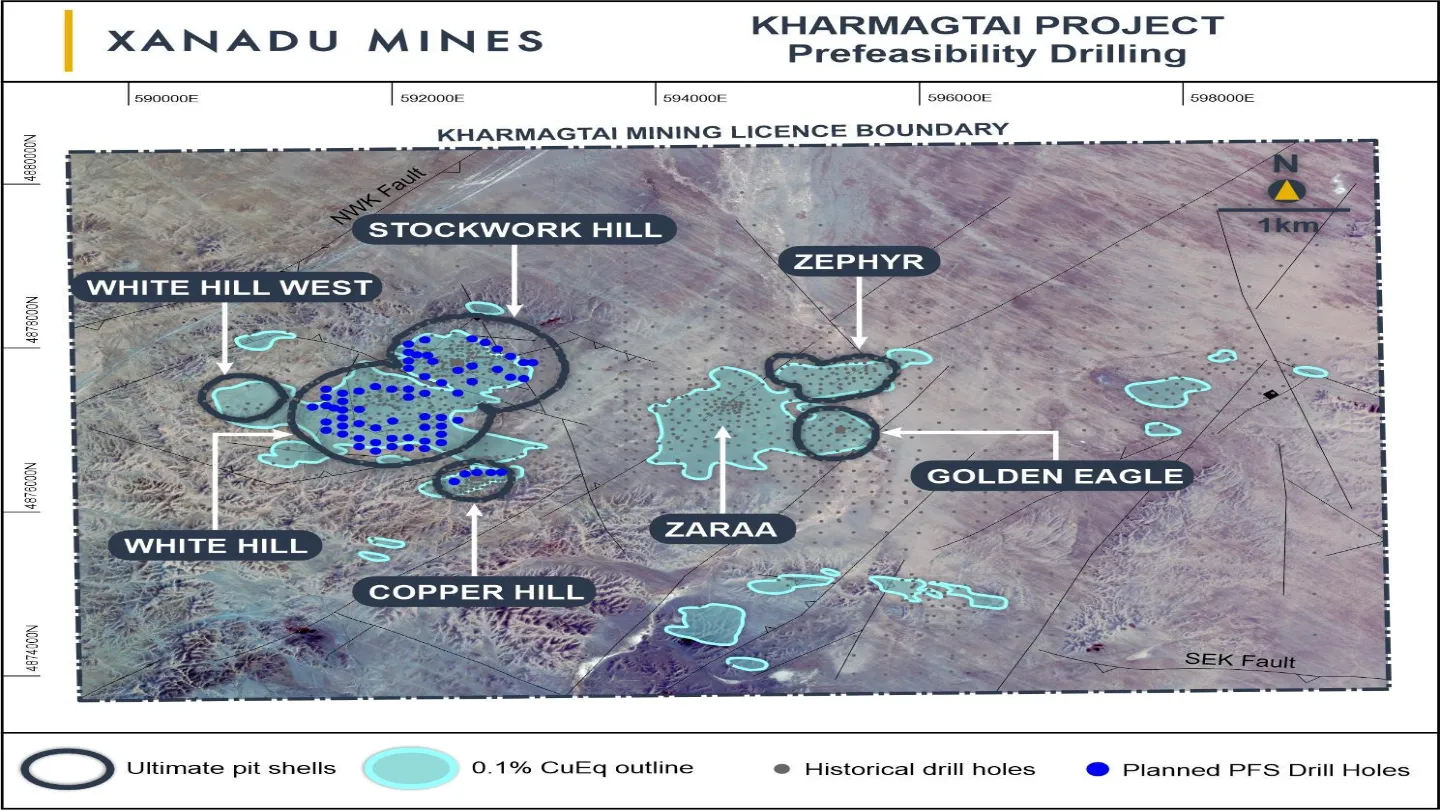

Key deposits at Kharmagtai include Stockwork Hill, White Hill, Copper Hill, Zephyr, Zaraa and Golden Eagle.

The Stockworks zones at Copper Hill, White Hill, Golden Eagle and Stockwork Hill exhibit magnetic features in the regional dataset, while Zaraa and Zephyr are on the flanks of magnetic features.

Kharmagtai Mineral Resource Estimate

Xanadu Mines published an updated Kharmagtai Project Mineral Resource Estimate (MRE) in December 2023. The updated data bettered the previous estimate tonnes in material tonnes by 12% and contained CuEq metal by 13%.

The project is estimated to contain 790Mt in indicated category containing 3,000kt CuEq at a grading of 0.38%, 2,100kt copper at a grading of 0.27%, and 5,600koz gold at a grading of 0.22g/t.

Inferred mineral resource estimate of the mine is 460Mt containing 1,700kt CuEq at a grading of 0.37%, 1,300kt copper at a grading of 0.27%, and 2,800koz gold at a grading of 0.19g/t.

Mining and Ore Processing

The Kharmagtai Copper-Gold Project will be mined using a conventional open pit method consisting of drilling, blasting, loading, and hauling.

Primary mining fleet will consist of 550-tonne diesel hydraulic shovels, 220-tonne haul trucks, and 20m3 capacity wheel loaders.

The deeper ores at the site may be recovered using underground mining methods.

The ores will be fed into a processing plant comprising generic crushing, semi-autogenous grinding mill, Ball mill, and Crusher (SABC) comminution, rougher flotation, cleaner flotation along with final thickening and filtration circuits to produce a copper-gold concentrate.

A gyratory crusher with a 750kW motor will be used as a primary crusher. The grinding circuit will include a SAG mill with a 20MW motor, two MP1000 recycle crushers and one 20MW ball mill operating in closed circuit.

The grinded material will undergo two stages of flash flotation. The circuit will consist of roughers, rougher scavengers, regrind mills, cleaners, and cleaner scavengers.

It would recover coarse gold from the flash flotation concentrate and smelted to produce gold doré. The remaining flash float concentrate will enter the final concentrate.

After thickening, the final tails will be discharged to the tailing’s storage facility.

The final concentrate will be thickened, filtered, and stored in containers to be trucked to a nearby rail-siding facility and then transported to smelters via rails.

The project is expected to process 12Mtpa of ore in the first year. Subsequently, it will be ramped up to 15Mtpa for the next six years and further up to 30Mt for the remaining LOM.

Key Kharmagtai Project Infrastructure

A 416km-long recently completed rail line stretching from Tavan Tolgoi to Zuunbayan is connected to the Trans-Siberian railway. The project is situated around 10km north of the new railway.

Water will be sourced from a water resource located 8km from the project site.

Power requirement for the copper-gold project is estimated to be 55MW for the initial 15Mtpa operations and 110MW for the 30Mtpa operation.

Initially, site construction works will receive power from diesel generators. An existing 35kV transmission line situated approximately 10km towards the south of the site.

Subsequently, a 110kV line approximately 40km west of site will be used to procure power.

Kharmagtai Project Contractors

The 2024 amended PEA of the project was prepared by O2 Mining with the support of Spiers Geological Consultants (SGC). Open pit optimisation works were carried out by Whittle Consulting.

The 2022 PEA of the project was prepared by SRK Consulting. CSA Global conducted a scoping study on the project in 2019.