The Bonga North Deepwater Project is located off the coast of Nigeria. The project forms part of the Bonga field and will help sustain oil and gas production at the existing facility.

Shell Nigeria Exploration and Production (SNEPCo), a Nigerian subsidiary of Shell, holds a 55% stake in the offshore field.

Other partners are ExxonMobil affiliate Esso Exploration and Production Nigeria (20%), TotalEnergies Exploration and Production Nigeria (12.5%), and Nigerian Agip Exploration (12.5%).

The Final Investment Decision (FID) on the Bonga North Deepwater Project was taken in December 2024. The production from the field is expected to commence by the end of the decade (2030).

Once onstream, the project will support Shell in maintaining stable liquids production from its advantaged Upstream portfolio.

Bonga Field Location and Discovery Details

Bonga field is located in Offshore Marine License (OML) 118, in the deepwater Niger Delta around 120km from shore. It is the first major deepwater development in Nigeria.

The offshore field, situated in water depths of more than 1,000m, spans an area of 60km2.

The Bonga-1 well discovered high-quality crude oil in the location in 1996. The well encountered hydrocarbons in unconsolidated, Miocene, deepwater sands, with high porosity and permeability.

Appraisal and development pre-drill wells also confirmed hydrocarbon-bearing sands.

The Bonga Floating Production Storage and Offloading (FPSO) began production in 2005. It delivered its one-billionth barrel of crude oil in 2023.

The field also delivers gas to the Nigeria Liquefied Natural Gas Company Limited (NLNG) at Bonny Island for exports globally.

Bonga North Deepwater Development

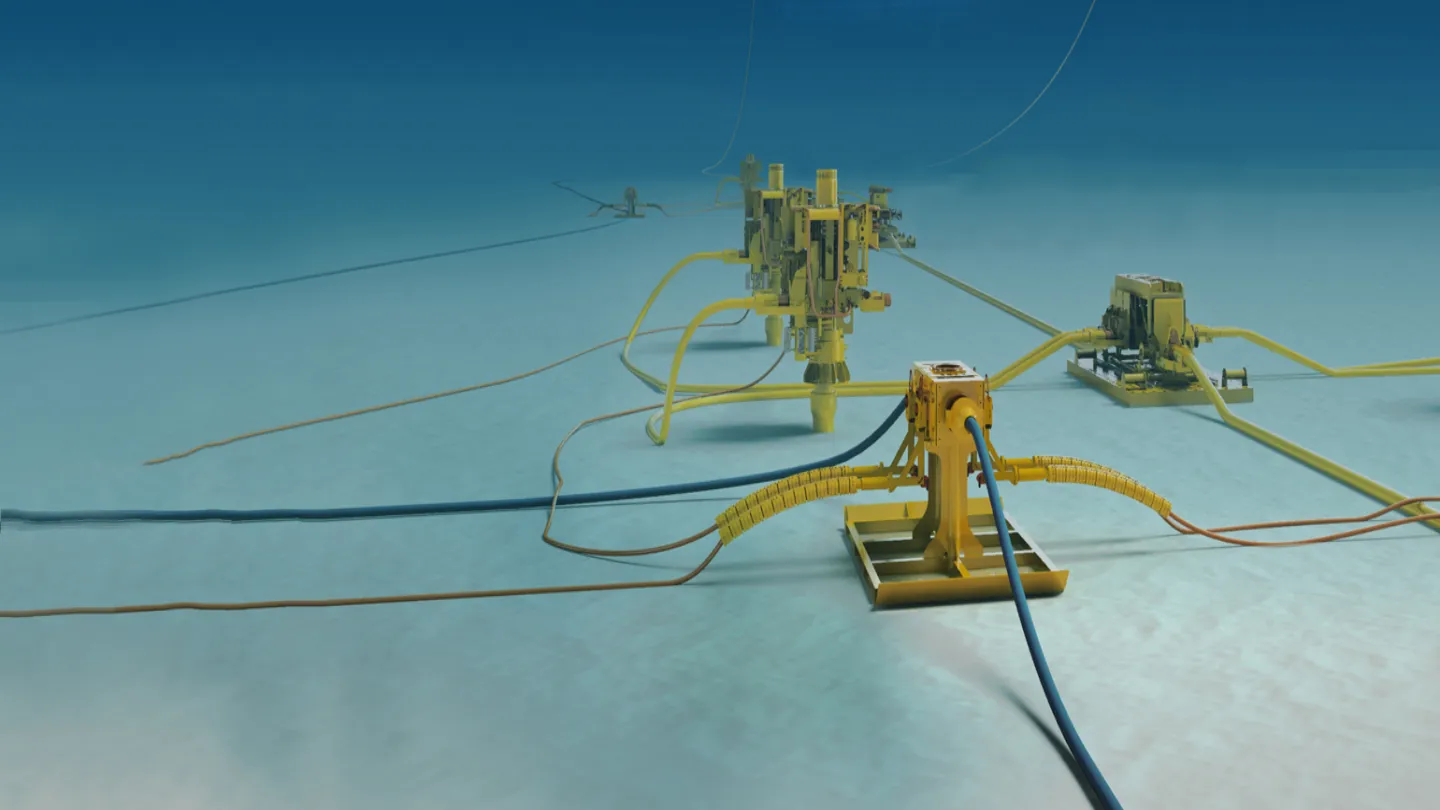

The Bonga North Deepwater Project will be developed via a subsea tie-back to the Shell-operated Bonga FPSO.

It includes drilling, completion, and commissioning of 16 wells. This will include eight production wells and eight water injection wells.

The existing Bonga main FPSO vessel will also be modified, and new subsea infrastructure will be installed.

The Bonga North project is estimated to hold more than 300 million barrels of oil equivalent (boe) in recoverable resources. The volume is classified as probable + proven (2P) reserves under the Society of Petroleum Engineers’ Petroleum Resources Management System.

Once operational, the offshore project will produce up to 110,000 barrels of oil per day at peak.

Contractors Involved

In December 2024, Shell Nigeria Exploration and Production selected a consortium comprising Saipem, KOA Oil & Gas, and AVEON Offshore for key offshore works related to the tieback of wells to the existing FPSO for Bonga North Deepwater Project.

The contract is valued at approximately $1bn, with Saipem’s share amounting to around $900m.

The scope of works for Saipem includes the Engineering, Procurement, Construction, and Installation (EPCI) of risers, flowlines, and subsea umbilicals and other subsea infrastructure for the project.

The design and fabrication works will be completed in Nigeria with local suppliers and contractors.

In December 2024, TechnipFMC won a contract to supply its Subsea 2.0 production systems for the project. The scope of the contract includes the designing and manufacturing of subsea tree systems, manifolds, jumpers, controls, and services.

As per TechnipFMC, the contract is valued between $250m and $500m.

Bonga Field FPSO

With a 300m length and the height of a 12-storey building, the Bonga FPSO is one of the largest of its kind in the world.

The 300m long deck is the size of three football fields.

The vessel weighs 300,000 tonnes when fully laden with oil and is moored by 500-tonne anchors connected by 20km of mooring lines.

The hull of Bonga FPSO was constructed by Samsung Heavy Industries. Subsequently, it was towed by tug boats to Wallsend in the north of England to undergo fitting with processing equipment modules.

Final equipment for the vessel were installed in Nigeria. Three of the Bonga modules, the foundation piles for the FPSO, the risers and the SPM buoy were also built in Nigeria.

It processes and stores oil and then sends it to a single point mooring (SPM) buoy nearby for loading onto tankers for export.