Bégin-Lamarche is a high-quality igneous phosphate deposit located in Québec, Canada. The project is owned by mineral development company First Phosphate.

In December 2024, the company announced a positive Preliminary Economic Assessment (PEA) on the Bégin-Lamarche Property. The project will entail an initial capital expenditure (capex) of C$675m ($480.4m).

The assessment estimated that the project could produce an annual average of 900,000 tonnes of beneficiated phosphate concentrate (apatite concentrate) at 40% P2O5 (phosphorus pentoxide) content and 380,000 tonnes of magnetite at 92% Fe2O3 (iron oxide) content over a 23-year mine life.

Bégin-Lamarche also holds the potential to recover ilmenite concentrate (titanium).

An internal Pre-Feasibility work is underway, following which, First Phosphate is expected to proceed with a Feasibility Study on the asset.

In January 2025, First Phosphate announced that Queen’s University and Université de Québec à Chicoutimi published two research reports on the mineralogy, petrology, and geochemistry of the Mountain, North and South Zones of the phosphate deposit.

Bégin-Lamarche Property Location

Bégin-Lamarche Property is located in Saguenay – Lac-Saint-Jean Region, northern Québec.

The location is around 270km north of Québec City and 75km northwest of the City of Saguenay.

It comprises 688 contiguous CDC claims with a combined area of 38,610 hectares (ha). These claims are registered with the Ministry of Natural Resources and Forests (MRNF).

The property can be accessed by secondary and tertiary roads that are connected to highways 170 and 172 west and northwest of Saguenay.

Geology and Mineralisation

The Bégin-Lamarche Phosphate Deposit is situated in an oxide-apatite gabbro intrusion underlain by rocks belonging to the Proterozoic age Lac-Saint-Jean-Anorthosite (LSJA) Suite, one of the largest phosphate mineralised anorthosite complexes in the world.

The Mesoproterozoic Bégin Megadyke crosses the property.

Primary rock types include norite, gabbro, troctolite, anorthosite and ultramafic rocks including nelsonite.

Bégin-Lamarche is categorised as an anorthosite massif-hosted phosphate (apatite) mineral deposit.

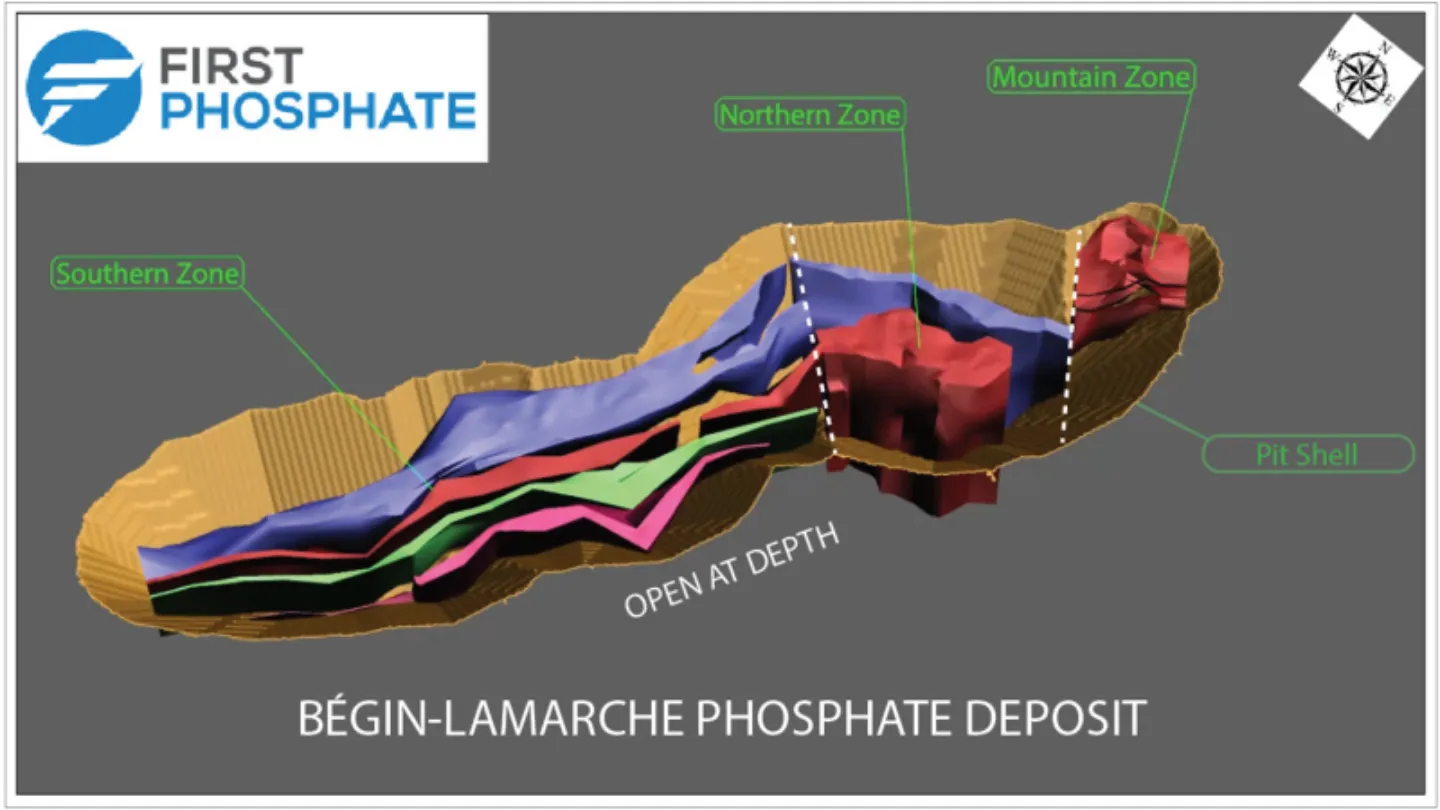

The deposit extends over 2,500m along its strike, features a steep dip, and is divided into three mineralised zones due to internal displacement along intersecting faults. The three zones are the Southern Zone; the Northern Zone; and the Mountain Zone.

The Southern Zone, the largest among the three, comprises four phosphate layers up to 200m thick, and stretches for 1,700m along strike.

The Northern Zone features two phosphate layers with a thickness ranging from 100m to 200m and extending 600m along strike.

The Mountain Zone has a single phosphate-bearing with an elongated mass up to 200m in diameter and 250m in length. It contains massive apatite (phosphate-bearing mineral) layers up to 2m thick.

Bégin-Lamarche Mineral Resource Estimate

The 2024 Bégin-Lamarche Mineral Resource Estimate (MRE) comprises an indicated mineral resource of 41.5Mt with a grade of 6.49% P2O5, 10.69% Fe2O3, 3.31% TiO2 containing 2,692kt of P2O5, 4.4Mt of Fe2O3, and 1,372kt of TiO2.

Inferred mineral resource stands at 214Mt with a grade of 6.01% P2O5, 10.89% Fe2O3, 3.63% TiO2 containing 12,851kt of P2O5, 23.3Mt of Fe2O3, and 7,773kt of TiO2.

Mining at Bégin-Lamarche

The PEA considers a conventional truck-and-shovel open pit mining method at Bégin-Lamarche.

It will involve the use of 90-tonne capacity haulage trucks and shovels equipped with 10 cubic metre buckets. It will also involve the use of other mining equipment such as dozers, road graders, watering trucks, maintenance vehicles, and service vehicles.

The life of mine will include 22 production years and six months of pre-stripping.

Low-grade mineralisation will be stockpiled over the LOM, and it will be processed for an additional production year.

Mineralised material will be transported by haulage trucks to the nearby process plant, while waste rock will be dumped at a facility situated 800m away from the open pit. Around 61Mt of waste rock is planned to be used to backfill the mined-out open pit.

Initially, mining activity is to be conducted at a rate of 15 million total tonnes per annum (Mtpa), and it will ramp up to 28 Mtpa based on process plant feed and waste rock removal requirements.

Mining activity will commence from the Mountain Zone, which hosts highest grade material, followed by the first phase of the Northern Zone and then the first phase of the Southern Zone.

At peak in Year 10, Bégin-Lamarche project will employ approximately 184 personnel, including operators, maintenance, supervision, and technical staff.

Recovery

The processing will include the initial crushing of ROM material using a gyratory unit, followed by grinding in a SAG-ball mill.

Magnetic separation at varying intensities will produce a magnetite concentrate, while moderate-strength multi-stage flotation will yield a high-grade apatite concentrate.

The process will also require high-density slurry reagent conditioning, along with regrinding of rougher magnetite and first cleaner apatite concentrates.

Subsequently, the concentrate slurry will be thickened followed by pressure filtration, drying, and preparation for shipping both magnetite and apatite products.

The primary product will be a high-grade apatite concentrate, to be produced at a projected rate of 900,000 tonnes per annum (tpa). This concentrate will be suitable for producing purified phosphoric acid (PPA), a key input for electric vehicle (EV) battery manufacturing and other high-value phosphorus products.

Conversion of the apatite into phosphorus compounds for these applications will take place off-site.

The processing plant is designed to operate for 336 days annually. Processing throughput will start at 10,300 tonnes per day (tpd) in the first year, increase to an average of 15,800 tpd during Years two to four, and further rise to 20,800 tpd from Year five onwards.

The current process flowsheet does not include ilmenite concentrate production.

Bégin-Lamarche Project Infrastructure

The Bégin-Lamarche Phosphate Project site benefits from some existing key infrastructure, including a 735kV transmission line maintained by Hydro-Québec, located approximately 25 km southeast of the site, and a well-maintained access road network.

Planned infrastructure for the project includes an open-pit mine, a primary crusher, and a process plant with a laboratory, main electrical substation, and power distribution system.

Storage facilities will consist of three dry-stacked tailings areas, a waste rock storage area, overburden stockpiles, and a low-grade mineralisation stockpile.

Water management infrastructure will include water collection basins and a central treatment plant.

Additional auxiliary facilities will include a main access road with a gatehouse, an administration building, warehouses for mechanical parts and process plant supplies, a maintenance building for mining equipment, explosives storage, water and sewage treatment plants, and a diesel fuel storage and fuelling station.

Contractors Involved

The Preliminary Economic Assessment (PEA) of the Bégin-Lamarche Phosphate Property was prepared by P&E Mining Consultants with inputs from BBA Inc.

P&E also completed an Initial Mineral Resource Estimate on the property with an effective date of September 2024.