North Island copper-gold project in the Canadian Province of British Columbia is being developed by junior resource company Northisle Copper and Gold.

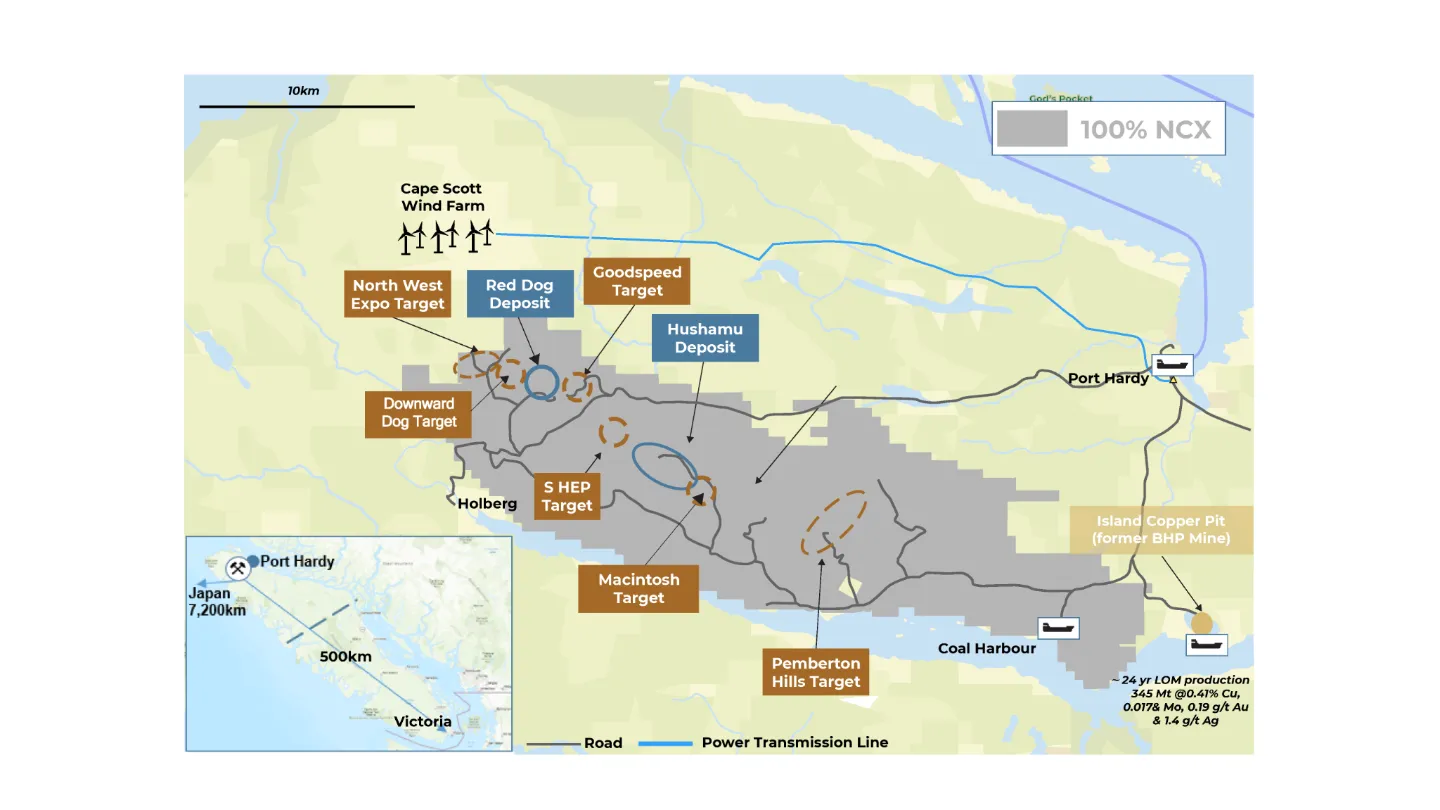

The project includes Hushamu, Red Dog and Northwest Expo deposits along with several partially explored copper-gold porphyry occurrences.

Northisle completed a preliminary economic assessment (PEA) for the North Island Project in 2021.

The company then released an integrated resource estimate for the copper-gold project in October 2024.

This estimate will be used for the preparation of an updated PEA on the North Island project. The PEA results are expected to be announced in the first quarter of 2025.

North Island Project Location

The North Island Copper and Gold Project is located on northern Vancouver Island, British Columbia. The site is approximately 20km south of Port Hardy, adjacent to the former Island Copper Mine.

The project includes a 33,397-hectare contiguous block with 210 mixed legacy and cell mineral claims.

It can be accessed from Port Hardy via paved roads and then well-maintained logging roads.

Geology and Mineralisation

Vancouver Island consists of Upper Paleozoic to Lower Mesozoic rocks from Wrangellia, a tectonostratigraphic terrane that extends discontinuously northward to Alaska.

The Hushamu and Red Dog Deposits contain porphyry copper-gold-molybdenum mineralisation.

The Hushamu Deposit primarily features early to mid-Jurassic Bonanza Group volcanics and the Mid-Jurassic Island Plutonic Suite. Five key lithological units present in the area include andesite, diorite, quartz-feldspar porphyry, hydrothermal breccia, and late breccia.

Most of the alteration and mineralisation occurs within the massive andesite. The deposit is divided into three mineralised zones- the Leached Zone, Supergene Zone, and Hypogene Zone.

At the Red Dog Deposit, the geology comprises lower Jurassic Bonanza Group andesitic to basaltic flows, tuff breccias, and tuffs, which have been intruded by four distinct Jurassic-age Island Intrusions.

Northwest Expo, Goodspeed and Macintosh are relatively untested targets.

North Island Project Mineral Resource Estimate

According to the updated resource estimate released in October 2024, North Island Project contains Indicated Resource of 906 million tonnes grading 0.16% Cu and 0.24g/t Au, 75 ppm molybdenum (Mo) and 0.42ppm Rhenium (Re), for total contained metal of 6.3 billion lbs copper equivalent (Cu Eq).

Inferred Resource stands at 214 million tonnes grading 0.12% Cu, 0.22g/t Au, 52ppm Mo and 0.31ppm Re for 1.3 billion lbs Cu Eq.

Mining and Processing

The PEA report published in 2021 states that the Hushamu and Red Dog Deposits will be mined using conventional truck-and-shovel methods. The mine design outlines a 22-year operation delivering 75,000 tonnes per day (t/d) to the concentrator.

The mining rate will peak at 64 million tonnes per annum (t/a).

The Hushamu open pit will be developed in four phases, initially supplying 50,000 t/d, while Red Dog will contribute 25,000 t/d. Both deposits will have pit rim crushers feeding overland conveyors to the processing facilities.

The mining fleet will include four production drills, three hydraulic shovels, and two wheel loaders, with a peak truck fleet of 18 220-tonne units.

Waste rock from Hushamu will be used in tailings dam construction and stored within the Mine Waste Storage Facility (MWSF), where it will be covered with tailings and an overburden cap.

The process plant, designed for a throughput of 75,000 t/d, will utilise a conventional copper/molybdenum flotation process.

Run-of-Mine (ROM) material from both deposits will be crushed, stockpiled, and processed through a SAG/Ball mill grinding circuit to achieve a size suitable for flotation.

The flotation process will begin with bulk copper-molybdenum flotation, followed by molybdenum separation to produce copper/gold concentrate and molybdenum concentrate as saleable products.

Pyrite will be removed from the bulk flotation rougher tails in a scavenger flotation circuit to generate low-sulphide tailings. The tailings will be classified, with the underflow used as sand for tailings dam construction and the overflow sent to the MWSF. Pyrite scavenger concentrate will be thickened and deposited sub-aqueously with fine flotation tailings in the MWSF.

Finally, copper/gold concentrate will be filtered, loaded onto highway haul trucks, and shipped to market. Molybdenum concentrate will be filtered, dried, and packaged before shipment.

Over its life, North Island Project can produce up to 1.8 billion pounds of copper, 1.7 million ounces of gold and 55 million pounds of molybdenum.

Key Infrastructure

A new 36km, 138 kV power line will be built to connect the mine site to an existing BC Hydro substation in Port Hardy. Additionally, a 28km 34.5 kV power line will be constructed for site distribution.

According to the PEA, the process plant is expected to meet its water needs without requiring external sources.

The proposed MWSF will be situated in the Hushamu Valley, immediately southeast of the Hushamu Pit.

Contractors Involved

The 2021 PEA for North Island Project was prepared by M3 Engineering & Technology. Personnel from GeoMinEx Consultants, Nilsson Mine Services, Phil Burt Consulting Services and Golder Associates also contributed.