The Southwest Research Institute (SwRI) in the US has developed a new modular steel buttress dam system that has been designed to help resolve energy storage issues hindering the integration of renewable resources into the energy mix.

The m-Pres dam system facilitates the rapid construction of paired reservoir systems for grid-scale energy storage and generation using closed-loop pumped storage hydropower (PSH). It claims to cut dam construction costs by one-third and reduce construction schedules by half.

“Pumped storage hydropower accounts for approximately 95 percent of all energy storage in the US, and modern PSH plants have a round-trip efficiency approaching 80 percent,” says Dr. Gordon Wittmeyer, a hydrologist in SwRI’s Chemistry and Chemical Engineering Division. “However, only one moderate-sized 40MW PSH plant has been constructed in the past two decades in the US.”

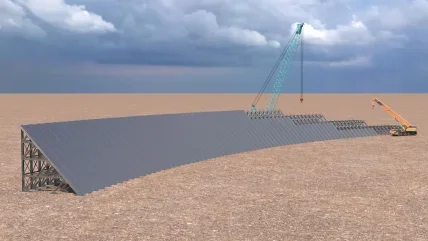

SwRI created m-Presa to accelerate the deployment of closed-loop pumped storage hydropower units where both the upper and lower reservoir sites can accommodate circular or rectangular reservoirs on relatively flat terrain, such as caprock mesas with level tops, steep-sided slopes, and gently sloped valley floors. The prefabricated structural members are more than 3m high and 3-12m long so they can be trucked to the site using standard or low trailers via the interstate highway system. Structural elements are assembled on-site using common heavy construction equipment to erect the buttress framework, whose face is subsequently clad with cylindrically curved steel plates.

Wittmeyer says that three factors currently stand in the way of rapidly deploying PSH: cost to construct, time to construct and potential environmental impacts. However, he claims the new m-Presa system addresses all of these issues.

SwRI says that current cost factors continue to deter new investment in PSH and include large capital costs (as much as $5000 per kW of installed capacity) and the lack of clear energy storage pricing signals. However, the m-Presa design could reduce construction costs to $1500 per kW-installed capacity, making PSH competitive with other long-term energy storage modes.

The time to construct reservoirs is a significant cost component as well. It often takes ten years to site, design, construct, and commission a conventional PSH plant at a time when private investors are realising paybacks of ten years or less from subsidised solar and wind farms. Reducing the time between project initiation and revenue generation could make PSH more attractive than other solutions used to manage huge daily swings in solar generation, such as non-sustainable gas peaking plants or shorter-lived battery energy storage systems.

Potential environmental impacts of reservoir construction are another significant impediment to the adoption of PSH when impounding a natural waterway. Potential environmental impacts associated with closed-loop PSH can be reduced or avoided if the upper and lower reservoirs are created by constructing fully enclosed dams separate from natural streams or rivers.

“The m-Presa system uses strong, long-lived steel buttress dams to create water impoundments that can store hundreds to thousands of MWhs of energy to supply power during periods of peak demand and provide ancillary services for grid stability,” Wittmeyer said. “A PSH unit using the m-Presa system can be constructed in less than half the time needed for traditional PSH units that use earthen embankment or concrete dams to impound water.”

AI advances

Meanwhile, Canada’s Ocean Supercluster has unveiled the HydroAware Project, an initiative to advance hydropower capabilities while ensuring the conservation of aquatic habitats through AI-powered fish monitoring.

Led by Innovasea in Nova Scotia, the project is a collaborative effort with the Fundy Ocean Research Centre for Energy, BigMoon Power, Nova Scotia Power, New Brunswick Power Corporation, and DeepSense, and is set to enhance fish tracking technology in challenging marine environments, improving the accessibility of fish tracking insights in remote locations.

Hydropower companies often find themselves at the intersection of energy production and environmental conservation, facing the challenge of minimising the impact on fish populations by their infrastructure while adhering to stringent regulations. The project is expected to bring about crucial advancements in fish tracking technology to address existing challenges such as streamlining approval processes for tidal stream and hydropower projects, reducing regulatory hurdles, and enhancing revenue opportunities within the renewable energy sector.

Fish tracking solutions play a pivotal role in monitoring fish behaviour and the HydroAware Project will usher in a new era for fish by incorporating AI. This will allow hydropower companies to collect more comprehensive data on fish behaviour, and expedite regulatory approvals.

Kendra MacDonald, CEO of Canada’s Ocean Supercluster, says that AI “has the potential to help transform the way we do ocean business”, adding that the project has brought together partners across different ocean sectors to advance AI in fish tracking technology, manage the movement of fish around hydropower infrastructure, support the sustainable growth of the industry and create economic benefits and jobs in the process.

“AI will enable us to monitor fish activity in environments that were previously too remote or inhospitable, ultimately serving as a catalyst for the next generation of hydro and tidal power facilities,” Mark Jollymore, President of Innovasea, adds.

The HydroAware Project builds upon the significant progress made by Innovasea in tagless fish detection technology, which provides hydropower producers with real-time data on fish activity in and around their infrastructure to achieve the dual mandate of wildlife protection and operational enhancement.

This article first appeared in International Water Power magazine.