Oxford PV, which describes itself as “the perovskite company”, plans to be a key player in what it sees as the solar-powered all-electric future. James Varley, a writer for Modern Power Systems magazine, takes a look at how the company aims to reach that target.

Next year, if everything goes to plan, Oxford PV will become the first company to sell perovskite-silicon-based solar cells to the residential rooftop market. They will have a potentially game-changing efficiency, about 20% higher than the current incumbent technology, silicon-only cells.

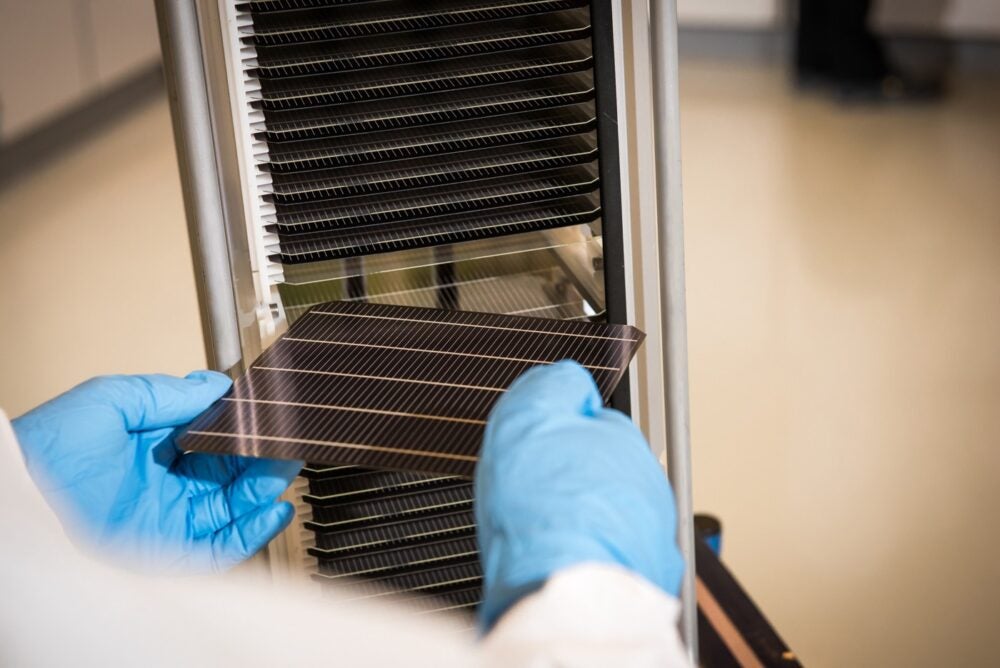

Oxford PV employs a “tandem” concept in which a thin film of perovskite is applied to a conventional silicon primary (or bottom) cell (the perovskite thickness being about 1/200th of that of the silicon).

This tandem approach improves the ability to capture specific parts of the solar spectrum, particularly at the high-energy, blue end, meaning that the perovskite-on-silicon tandem cell has a theoretical efficiency limit of 43% vs 29% for silicon-only cells.

In practice, the average efficiency of residential silicon PV installed to date is in the range of 15-20%, while the “real world” maximum for silicon is estimated to be about 26%.

The early commercially produced Oxford PV tandem cells are expected to achieve an efficiency of about 27% initially, but the company anticipates steady improvements as the technology develops in the coming years. “We have a clear roadmap to take this technology beyond 30%,” says CEO Frank Averdung.

Dr Chris Case, CTO at Oxford PV, notes that since 2014, when the company decided to focus exclusively on the perovskite-Si tandem, it has boosted the efficiency of its solar cell roughly by one percentage point per year on average and has a path and the theoretical foundations to further develop this technology all the way to the high 30s.

A research cell employing the Oxford PV technology has already achieved 29.52% (as certified by the US National Renewable Energy Laboratory), a world record for perovskite-Si tandem cells and also better than any single-junction research cell (for which the current record, 29.2%, is held by a cell employing GaAs).

Perovskite was first discovered in its naturally occurring mineral form (CaTiO3) in 1839 (coincidentally the same year as the photovoltaic effect was first observed, Chris Case points out). But it is only in the last ten years or so that the huge potential of synthetic perovskites as a material for solar cells has been fully recognised.

Prof Henry Snaith, who co-founded Oxford PV in 2010 to commercialise solar technology transferred from his laboratory at the University of Oxford (and is the company’s chief scientific officer), has played a key role in this, notably via a paper published in Science in 2012, describing a viable solid-state solar cell technology employing metal halide perovskite.

Progress over the past 10 years has been remarkably rapid and perovskites are attracting increasing interest in the solar field.

Like all materials used in solar cell applications, perovskites – for which the generic chemical formula is ABX3, where A and B are cations and X is the anion – are semi-conductors.

“Perovskites will be ubiquitous in photonics and electronics for the next 50-100 years,” Chris Case believes. “It’s that stunning a material.”

From a materials science standpoint, “there is a uniqueness, that’s why it’s so good,” he adds. “Each of the atoms is oriented as a set of octahedra that are stacked on top of each other, and twisted. That twist allows ‘anomalous’ high photocurrent diffusion, and that’s pretty much unique to this structure, and people are exploiting this property…This stuff is great, it’s unbelievably transformative.”

Also, the materials used for synthetic perovskites are abundant, and the amount used per unit of cell output is very small. “So, from a resources standpoint, the technology is capable of being scaled to the many TW level,” says Case.

And as well as demonstrating record efficiency, cells and modules using the Oxford PV technology have also “passed externally measured industry-standard reliability tests from the International Electrotechnical Commission,” he adds.

The route to market

“The scientists have done their job,” says Frank Averdung. “They have identified the material. They have made the structure. They have worked at making it stable and have addressed concerns about durability and lifetime. The question we have to figure out an answer to now is: how do we commercialise it?”

The challenge is one that is faced by pretty much every start-up with something new, he says. “You have an established market. You have established market players. You have something significantly better. But how do you get people to embrace it? How do you make it happen?”

As he points out, the established players are multibillion-dollar companies and they have invested billions into a manufacturing infrastructure. “Are they really interested in scrapping all of that and doing something new?” asks Averdung.

The good news is that the Oxford PV tandem technology, with silicon as the primary cell, does not require the jettisoning of existing manufacturing technology and “does not disrupt the industry”, and this is a major benefit.

“When we put a thin film perovskite cell on top of the silicon ‘primary’ cell, it still has the same form factor and still looks like a conventional Si cell, but the output voltage is higher,” says Averdung. “You can use the same tools and insert them into the same modules. The panel size is the same. Everything is the same. But you get significantly more power out.”

In terms of appearance the end-user will not notice any major difference, except it will “look a little bit nicer”, he adds.

In 2015, Oxford PV demonstrated that the tandem cell was feasible, but needed to “bring it to the required form factor”, he explains, so required a pilot production line or “used factory”.

Just such a factory was found in Brandenburg an der Havel, Germany, and acquired in 2016. “It was way too large for us that time but was a perfect fit for our thin-film pilot line”, which was up and running in 2017,” says Averdung.

“The role of the pilot line was, and still is, essentially product optimisation, taking all the results from the Oxford lab and scaling them up form-factor-wise and carrying out industry-standard testing to verify that the cells are achieving the required reliability and long term stability, and meeting industry needs.”

For some years, Oxford PV worked with a joint development partner, a very large company in the photovoltaics business, “basically telling us what the industry would want”, says Averdung.

But in 2018, he adds that “all that changed”, and the company decided the “best and fastest route to commercialisation of the technology would be to do it ourselves, enabling us to keep all the parameters of the technology under our control so we could be certain that the product, when it came to the market was a perfect fit to customer demands”.

This required the firm to find investors that would put money into it, enabling it to set up a manufacturing operation. “We were lucky”, says Averdung, as a number of supportive investors were found. The company’s major shareholders now include Equinor, Legal & General Capital, Goldwind and Meyer-Burger.

The money put into the company by investors made it possible to upgrade the Brandenburg factory previously acquired and, in addition to the pilot line already there, establish a full tandem cell manufacturing line in a different part of the facility.

This will be the world’s first volume manufacturing line for perovskite-on-silicon tandem solar cells and is expected to achieve an initial target capacity of 100 megawatts (MW) around Q2 next year.

The cells are being sold to module makers (arrangements are already in place), and the initial target market is the “premium” residential rooftop sector. In this segment of the market, space is a critical constraint and the increased power density provided by the Oxford PV tandem cell is particularly attractive.

With much more electricity generated over the installation’s lifetime, there is a willingness to pay substantial premiums for high-efficiency modules, Oxford PV believes.

Averdung points out the costs of the cells account for a relatively small proportion of the total costs of a residential rooftop PV installation, so increased cell costs have only a relatively small effect on the overall economics compared with the benefits of increased output.

Towards the gigafactory

The 100-MW manufacturing line, and the residential rooftop market, are seen as just the beginning. Oxford PV’s vision is an all-electric world with perovskites as a mainstream solar technology. It is hoped the company’s latest funding round will give it “the means to plan the next step, which is a gigafactory”, says Averdung.

He hopes to have 2 gigawatts (GW) of production capacity in operation by the end of 2024 or thereabouts, and then to add about 2GW per year, reaching more than 10GW by the end of the decade.

Initially, the target market is, as already noted, the premium residential rooftop, but “this will change once we get into GW scale production, then we will be able to address, in addition, the small-commercial rooftop sector”, says Averdung, and “as soon as we move to 5GW and beyond, utility-scale is within reach”.

At utility-scale, “it is all about LCOE”, he observes, “assuming the cost of your land is manageable”, and at 5-GW production capacity “our LCOE will be more competitive than anyone else’s, but that will take a few years, of course”.

In the end “we intend to become one of the major players in photovoltaics”, says Averdung. And mastering what Chris Case calls the “magic” of perovskites could prove to be the key to achieving that ambition.

This article originally appeared in Modern Power Systems magazine