Braskem is overhauling and undertaking technological update for its existing cogeneration plant, which provides steam and power to the petrochemical complex’s cracking unit. Work is scheduled to be completed in early 2021.

The cracking unit, which is designed to have ethylene production capacity of 700,000 metric tons per year (kta), produces raw materials for the chemical and plastic sectors.

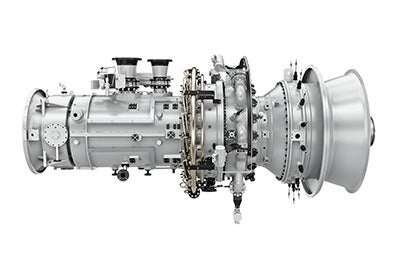

As part of the upgrade project, Siemens will implement a fully integrated and redundant equipment solution, including two SGT-600 gas turbines, and an E-house.

Siemens will also be responsible for an extension of the existing high-voltage substation, installation of three reciprocating compressors, an advanced load-shedding system, and associated software for plant control.

The two SGT-600 gas turbines, which will be installed at the cogeneration plant, will feature DLE technology and will run on residue gas with high concentrations of hydrogen.

In addition to increasing efficiency of the ethylene plant, the Braskem’s project is expected to reduce the cracking unit’s water consumption by 11.4% and CO2 emissions by 6.3%.

Braskem Chemicals southeast region chief industrial officer Luís Pazin said: “The modernization will help us meet our sustainability goals by reducing the facility’s overall energy consumption by an amount equivalent to that of a city with one million inhabitants.”

Additionally, Siemens will be responsible for engineering, deploying, operating, and maintaining the entire electric and steam cogeneration plant for 15-year period.

The long-term contract also includes performance guarantees for reliability, availability, efficiency, costs, maintenance, and emissions.

Siemens Gas and Power, Oil & Gas Global Solutions head Dan Simpson said: “Siemens was uniquely capable of proposing this comprehensive engineering and service solution that will help Braskem meet its sustainability goals and maximize value over the life of the cogeneration plant.

“The integrated and redundant design of the facility and use of Siemens equipment, coupled with the adoption of a build, own, and operate business model will result in 100 percent plant availability and reduced energy consumption, both of which are critical to Braskem’s business.”