Abra base metals project is an underground lead-silver mine being developed in the Gascoyne region of Western Australia. It represents one of the biggest undeveloped lead deposits in the world.

The project is being developed by Abra Mining, a joint venture of Australia-based Galena Mining (86.16%) and CBH Western Australia (13.84%). CBH Western Australia (CBHWA) is a wholly-owned subsidiary of Japan-based Toho Zinc.

The construction works on the project were started in October 2019 with the start of production expected in 2022. The initial capital expenditure for the project is estimated to be £88m (A$170m).

A feasibility study (FS) for the Abra base metals project was released in July 2019 following the completion of a pre-feasibility study (PFS) in September 2018.

The Abra underground mine is expected to produce a total of 1.24 million tonnes (Mt) of lead and 10.6 million ounces (Moz) of silver over an estimated mine life of 16 years.

Location, geology, and mineralisation

The Abra base metals project is situated approximately 200km north of Meekatharra in the Gascoyne region of Western Australia. The project site lies between the towns of Newman and Meekatharra.

Abra is a polymetallic replacement deposit hosted by sediments of the Proterozoic Edmund Group. Apart from possessing lead as the primary economic metal, the deposit also contains a significant amount of silver along with some presence of copper, zinc, and gold.

The Abra deposit is broadly divided into two mineralised zones including the upper overlying Apron Zone that consists of stratiform massive and disseminated sulphides and the underlying Core Zone which is characterised by an elongate funnel-shaped orebody comprising hydrothermal breccias, veining and intensely altered overprinting sediments which dip to the south.

Ore reserves at Abra base metals project

The Abra base metals project is estimated to hold 10.3Mt of probable ore reserves grading 8.8% lead and 24g/t silver.

The indicated and inferred resources are estimated to be 37.4Mt grading 7.5% lead and 18g/t silver.

Mining and ore processing

The underground mining method with long-hole open stoping will be implemented for the Abra base metals project. The room and pillar mining method will also be adopted for mining shallow dipping areas in the Apron Zone.

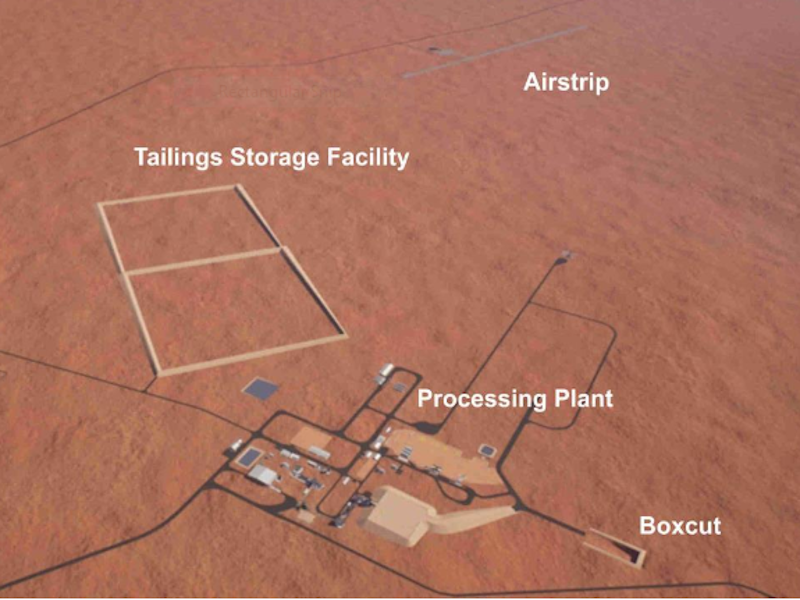

The construction of a 190m-long, 45m-wide, and 25m-deep box-cut for the underground mine was completed in April 2020. The box-cut will house the main portal for the mine decline.

The extracted ore from the mine will be sent to a nearby processing plant where it will undergo three-stage crushing, a single-stage grinding in a ball mill, floatation, and regrinding for the production of lead-silver concentrate. The capacity of the floatation process plant will be 1.2 million tonnes per annum (Mtpa).

The obtained concentrate will be dewatered, thickened, and filtered before being packaged and transported to the Port of Geraldton for shipping.

Infrastructure facilities for the Abra base metals project

The Abra base metals project site is accessible through unsealed roads connecting the Great Northern Highway. An aerodrome to service the project site will be constructed approximately 3km east of the process plant.

An accommodation village for up to 284 personnel is also being developed as part of the project.

The electricity for the project is planned to be met through a modular gas-fired power generating facility onsite. The power plant is planned to be integrated with photovoltaic solar installations and a battery storage facility.

The water requirement for the project will be met through mine dewatering as well as water supply from the aquifers located within 7km of the processing plant.

The other infrastructure facilities for the project will include an 8.5Mt tailings storage facility (TSF), mine workshops, water supply, storage, and reticulation facilities and an LNG storage facility for the power plant.

Contractors involved

GR Engineering Services (GRES) was awarded the engineering, procurement, and construction (EPC) for the process plant of the Abra base metals project in February 2020.

GRES was also engaged to provide process design, metallurgy review, and infrastructure design services during the feasibility studies for the project.

Keogh Geotechnical Consulting provided geotechnical services while Rockwater provided hydrology services.

Other consultants engaged during the feasibility studies included Mineralis, Opitro, GALT, Stantec, Platek Analytics, and ALS Metallurgy.