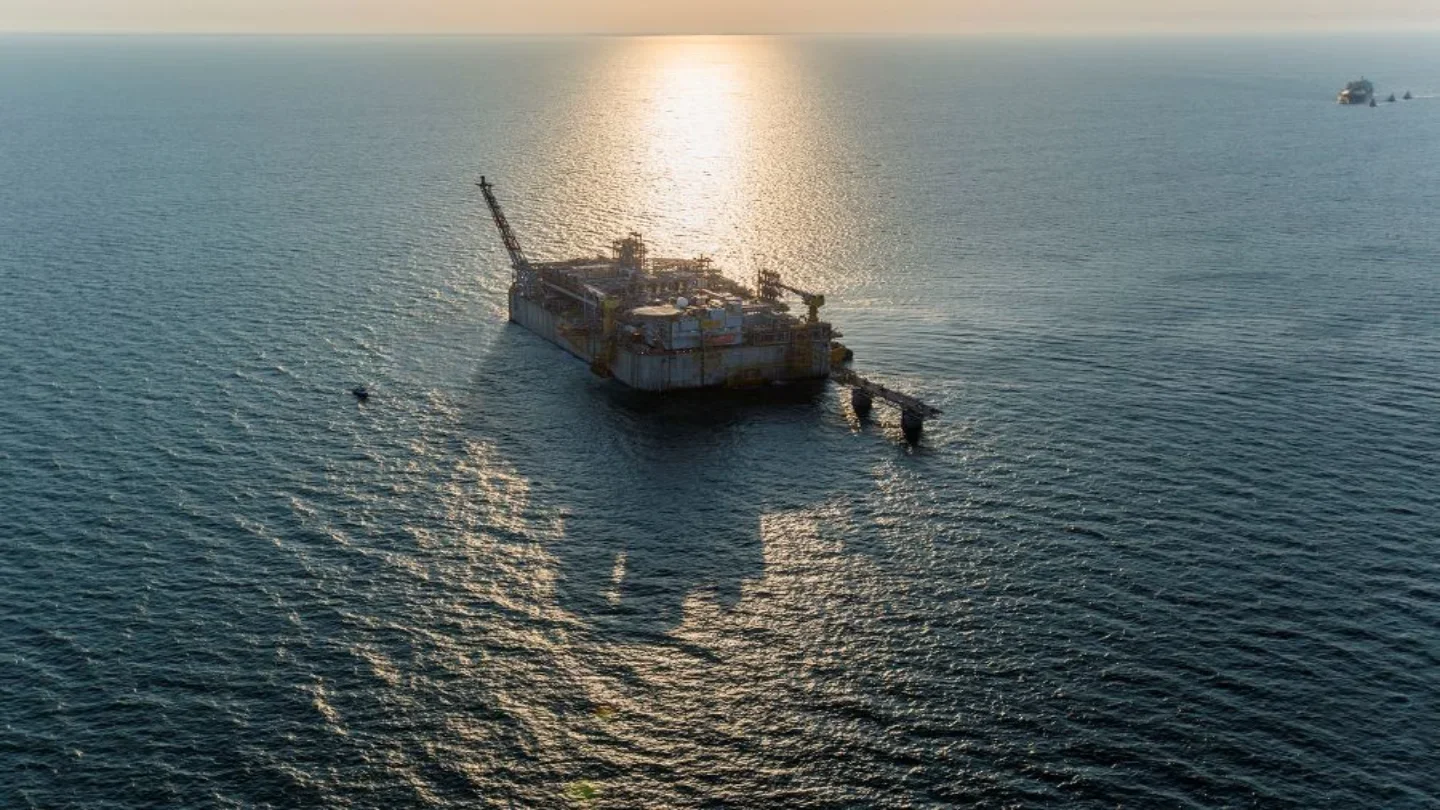

The Adriatic LNG Terminal is an offshore liquefied natural gas (LNG) regasification facility located in the Adriatic Sea.

The facility is one of the first offshore gravity-based structure for LNG unloading, storage, and regasification in the world.

Dutch storage terminal owner VTTI holds 70% stake in Terminale GNL Adriatico, the company which operates the terminal. Snam, a gas infrastructure operator in Europe, owns the remaining 30% interest.

Adriatic LNG Terminal commenced operated in October 2009. By providing more than 10% of the national natural gas consumption, the facility plays a crucial role in enhancing Italy’s energy infrastructure and supply security.

Adriatic LNG Terminal Location

The Adriatic LNG Terminal is situated in the Adriatic Sea, approximately 15km off the coast of Porto Levante in the Rovigo Province of Italy’s Veneto region.

The Adriatic Sea is the water body that separates the Italian Peninsula from the Balkan Peninsula.

It is the largest LNG terminal in Italy and one of the key terminals operational in the Mediterranean area.

Background

The terminal was developed by a consortium comprising ExxonMobil Italiana Gas, Qatar Terminal (a subsidiary of QatarEnergy), and Edison. The ownership structure of Terminale GNL Adriatico gradually evolved over the years.

In December 2024, VTTI acquired 70% stake in Adriatic LNG, while Snam increased its stake to 30%, after the sale of shares by ExxonMobil and QatarEnergy.

In 2023, Adriatic LNG imported 8.5 billion cubic metres (bcm), which represents more than 14% of Italy’s national gas consumption in the year.

Adriatic LNG Infrastructure Details

Main Adriatic LNG terminal infrastructure includes a reinforced gravity based concrete structure; two LNG storage tanks within the structure; a regasification plant; mooring and unloading components for LNG carriers; accommodation quarters; and a methane pipeline connected to the mainland.

The gravity-based structure (GBS) is anchored to the seabed at a depth of about 29m. The structure is 180m long, 88m wide and 47m high, built using 90,000m3 of cement and 30,000 tonnes of steel reinforcement.

The two LNG storage tanks are of 125,000m3 each, while the regasification plant is located on the main deck of GBS.

The regasification facility hosts four LNG vaporisers; a heat recovery LNG vaporiser; two cryogenic compressors; four pumps to transfer LNG from tanks and five other pumps to send the gas into vaporisers and the pipeline.

The mooring facilities, known as Mooring Dolphins, can accommodate LNG carriers of varying tonnage.

There are special output arms that are used to move the LNG from the ship to pipelines and subsequently to the terminal storage tanks.

The living quarters can accommodate up to 60 people. It includes housing, offices, a fully equipped kitchen, medical facilities, a laundry room, a heliport, and communal areas.

Overall, the LNG pipeline runs for 40km- 15km under the seabed and then 25km inland to the Cavarzere (Ve) measuring station.

An Infrastrutture Trasporto Gas-owned second pipeline transports the gas for 84km to the national grid junction near Minerbio.

Additionally, the terminal features a modern control room that allows the operators to control and monitor all operational aspects.

There is also a centre in Terra di Porto Viro (Ro) that operates as a ground operations base.It comprises a 50,000m2 complex, a mooring dock, offices and telecommunication systems.

The centre maintains constant connection with the platform, and a warehouse for supplies and replacement material; and support activities related to the movement of vehicles and personnel to and from the terminal.

Contractors Involved

Spanish engineering company Acciona was associated with the construction of the Adriatic LNG terminal. Kværner served as designing consultant on the project, while Jan De Nul Group performed dredging works.

In February 2024, Technip Energies secured a contract to refurbish the terminal’s last two offshore LNG loading arms. A plug and play solution is expected to be deployed to minimise downtime of the LNG terminal.