Araguaia project is a Tier 1 nickel laterite mining project being developed in the state of Pará, Brazil. It is regarded as Brazil’s next major ferronickel mine and one of the biggest undeveloped saprolite nickel projects in the world.

Horizonte Minerals fully owns the tier-1 mining project, which is estimated to have a mine life of 28 years.

Feasibility study (FS) of the ferronickel project was completed in October 2018 and the construction license was granted by the State Environmental Agency (SEMAS) of Para in January 2019.

Horizonte expects to start construction of the project in the third quarter of 2019 and complete in 2021. First nickel production is anticipated to be made in the fourth quarter of 2021 with ramp up to steady state expected in 2022. The development is expected to create 1,000 construction and 500 operational jobs.

It is expected to produce 52,000 tonnes (t) of ferronickel, containing 14,500t of high-grade nickel per year, using a single-line rotary kiln electric furnace (RKEF) plant in the first stage. A second RKEF plant is also proposed to expand the production to 29,000tpa in the second stage.

Araguaia nickel project geology and mineralization

The Araguaia nickel project is situated in the southern part of Carajas Mining District in Para and approximately 25km west of the north-south trending Araguaia River. It lies within the Neoproterozoic Araguaia Fold Belt, a north to south trending orogenic zone.

The project area hosts a distinctive lateritic sequence developed over ultramafic and mafic rocks. The sequence is further divided into six facies types namely soil, ferricrete, limonite, transition, saprolite, and fresh rock.

Nickel laterite mineralization occurred in a seasonally wet tropical climate on moderately serpentinised ultramafic rocks. It comprises three distinct horizons -limonite, transition, and saprolite.

Araguaia nickel project reserves

The proven and probable reserves of the Araguaia nickel project were estimated to be 27.29Mt, grading 1.69% Ni, 17.15% Fe, and 4.94Al2O3, as of November 2018.

Mining at Araguaia Ferronickel project

Conventional open-pit truck and excavator mining methods will be applied at the Araguaia nickel laterite project. The mining fleet will comprise 20-30t excavators, 25-50t dump trucks, and 20-25t wheel loaders along with dozers and graders.

The Araguaia project hosts two principal mining centers – Araguaia Nickel South (ANS) and Araguaia Nickel North (ANN). ANS is made up of seven deposits namely Pequizeiro, Baiao, Pequizeiro West, Jacutinga, Vila Oito East, Vila Oito West, and Vila Oito, while ANN hosts the Vale do Sonhos deposit.

Ore processing at Araguaia

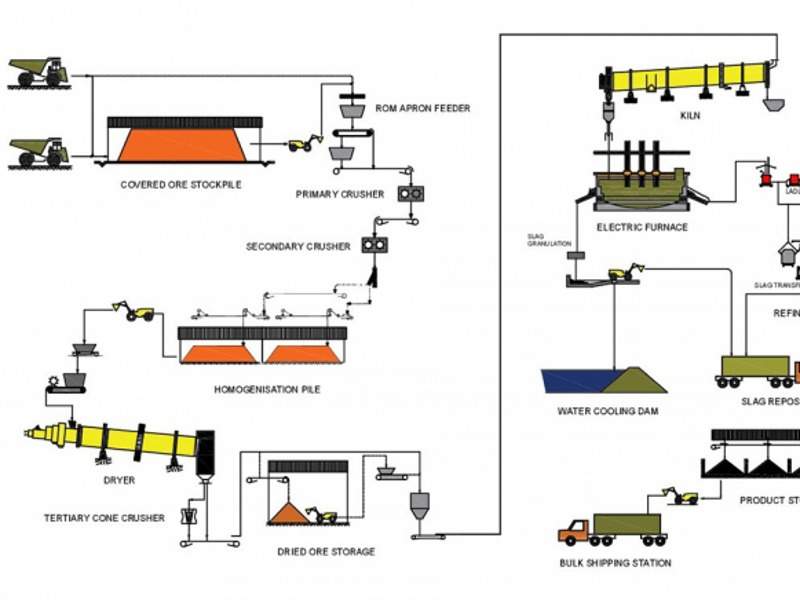

Rotary Kiln-Electric Furnace (RKEF) will be employed to process the run-of-mine (ROM) ore at Araguaia.

The ROM ore, with an average moisture content of 34%, will be crushed and sized in two stages. It will be homogenized, partially dried, and agglomerated in a rotary dryer to bring its moisture content to 18%, before being firing using pulverized coal.

The dried agglomerated ore will be forwarded to the rotary kiln, where reductant coal will be added. The ore will be completely dried and calcinated to remove chemically-combined moisture, and partially pre-reduce iron and nickel oxides.

Calcine from the kiln will be forwarded to the electric furnace where further reduction of nickel and iron oxides will be achieved. Metal will be melted at high temperature to separate slag and transferred by ladle to the refining stage to produce final ferro-nickel (FeNi) product containing 30% nickel (Ni).

The final FeNi will be watered, screened, dried, stockpiled, and transported to the port of Vila do Conde. It will be bagged into sea containers and loaded onto ships for export to customers.

Infrastructure facilities at Araguaia Ferronickel project

The ANS section of the Araguaia nickel project will be accessed via BR-155, a two-lane federal highway from Marabá, while ANN can be accessed from Marabá or from the town of Araguaína.

Water will be sourced from the Araguaia river by the barge pump station and collected in a tank. A water cooling dam will also be constructed to supply water to the processing plant. It will also act as a heat sink for the furnace.

Power supply for the project will be made from the national grid by constructing a new 122km-long, 230kV transmission line from the plant substation to the Xinguara II substation.

A slag storage facility will be developed with a capacity of 20.44Mt and a total footprint of 60 hectares.

Contractors involved

Pacheco e Filhos was awarded the drilling contract, while Endeavour Financial was engaged as the financial advisor, in October 2018, for securing project finance.

The feasibility study of the project was prepared by a group of consultants including Ausenco, Prime Resources, C.Steinweg Group, Worley Parsons Group, and Environmental Resource Management. Snowden also participated in preparing the technical report of the project.

In June 2017, VCE Mine consultancy was engaged for mining permit reporting as part of the FS, while Steinweg Handelsveem was engaged for studying material transport and logistics costs.

In June 2018, Horizonte Minerals engaged SM&A Servicos Eletrics for the design engineering of the 230kV transmission line.

Brandt Meio Ambiente and Geoid Laser Mapping were contracted respectively for preparing the installation environmental permits and for conducting geoid laser mapping required for the powerline installation.