Arizaro Project in the Salta Province of Argentina is majority owned by Canada-based exploration and lithium resource company Lithium Chile. The company runs its operations in Argentina via its subsidiary Argentum Lithium.

A Preliminary Economic Assessment for the project was completed in August 2023. This was followed by the announcement of the Pre-Feasibility Study (PFS) results in July 2024.

According to the PFS, Arizaro Project can produce 25,000 tonnes per annum (tpa) of battery grade Lithium Carbonate Equivalent (LCE). Life-of-Mine (LOM) duration is estimated to be 20 years.

The project will require an initial capital of $1.05bn, with a sustaining capital estimated to be $246m.

Lithium Chile has signed a binding Letter of Intent (LoI) in December 2024 to sell 80% interest in the project to an Asian based company for $180m. The LoI has a 90-day exclusivity period.

Before signing the LoI, the company shifted the ownership to a newly established subsidiary, Geo Inversiones Mineras in order to separate its other Argentine property Block IV from the Arizaro Project.

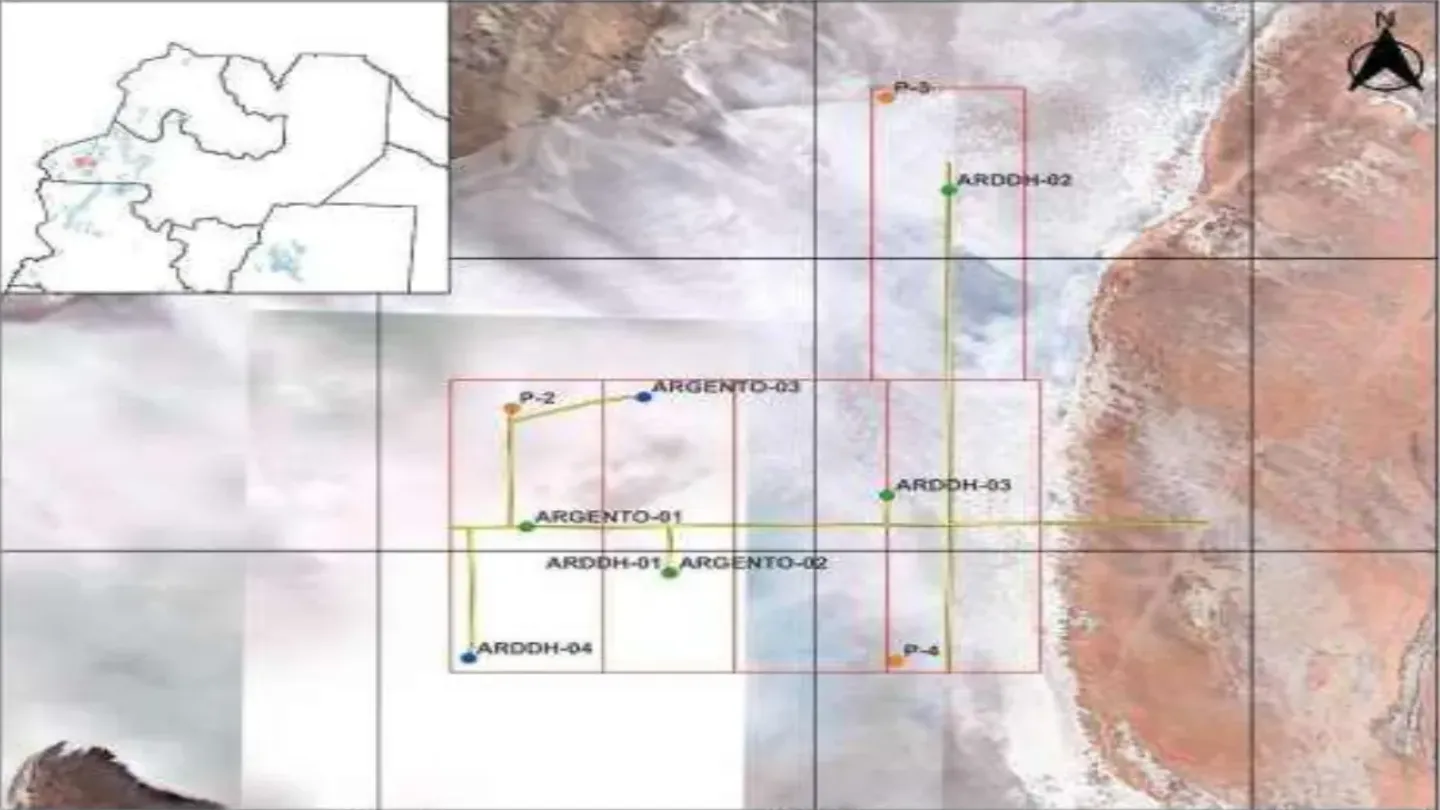

Salar de Arizaro Project Location

Arizaro is located in the Salar de Arizaro basin in the Argentinian Puna at an elevation of approximately 3,475 metres above sea level (m asl). The project lies approximately 230km from Salta and approximately 38km southwest of the Tolar Grande town.

The project consists of a total of six exploration and exploitation concessions (minas) and exploration permits (cateos) covering 20,500 hectares (ha).

Accessibility to the site from the city of Salta via the national route RN-51. The route connects through the towns of Campo Quijano and San Antonio de Los Cobres.

Arizaro Geology

Arizaro is located within the Puna Austral Geological Sub-province of the Geological Province of La Puna.

Puna is characterised by the presence of evaporitic basins called salars containing borates, sodium sulphate and lithium concentrate as deposit.

La Puna hosts evaporitic basins or salars containing deposits of borates, sodium sulphate, and lithium.

The northern concessions of the project are surrounded by Holocene alluvial and colluvial deposits, and underlain by the recent evaporitic deposits.

The older sediments from the northeastern area are of Oligocene Lower Miocene Vizcachera Formation. These include sandstones, volcanic sandstones, pelites, tuffs, gypsum, and halites.

The boundary of the project is made up of older granodiorites of Upper Ordovician Formation found towards northwest, Taca Taca Formation, dacites, ignimbrites, and dacitic tuffs of Eocene Santa Ines Volcanic Complex.

Halites are around 200m to 500m trending from southwest to northeast, respectively.

Mineral Resource and Reserve Estimates

At 200mg/L cutoff grade, the measured mineral resource estimate for Arizaro Project is 261kt LCE with an in-situ lithium mass of 49kt at an average extracted concentration of 261mg/L.

The project contains 2,237kt LCE of indicated mineral resources containing 420kt in-situ lithium mass at an average extracted concentration of 302mg/L.

Inferred resources stand at 1,624kt (1.6Mt) LCE containing 305kt in-situ lithium mass at an average extracted concentration of 362mg/L.

The project hosts a total of 490kt LCE of probable reserves with an 92kt of extracted lithium mass at an average extracted concentration of 273mg/L.

Mining at Arizaro Project

Arizaro will produce LCE by operating brine extraction wells. The brine extracted from the wells will be temporarily stored in one collection/transfer pond and from there it will be transferred via a main pipeline directly to the receiving ponds located near the DLE plant.

A total of 35 production wells are expected to be drilled by Year 2 to meet the target of 25,000t/y of LCE, with their replacement expected to be considered after 8-12 years of operation.

The production wells will have an estimated average depth of 500m. A 12-inch stainless steel casing is under consideration for the wells.

Production will increase to 25,000t/y in Year 2 from 14,178t (57%) annual LCE production target in Year 1.

After the first year, approximately 660 litres per second (L/s) average brine feed rate with 273mg/L average extracted lithium concentration are expected from the project.

Recovery Method

The raw brine with a flow rate of 64,080m3/d will be necessary to achieve a production of 25,000t/y stored in one collection or transfer pond and pumped through a main pipeline to the receiving ponds located near the Direct Lithium Extraction (DLE) plant.

In the processing plant, the raw brine will undergo eight stages of treatment.

The direct lithium extraction (DLE) will involve using resins as a highly selective adsorbent to take out maximum lithium.

The solution enriched with lithium from the DLE will pass through membranes thereby increasing the concentration of lithium and recovering water. This process is known as reverse osmosis.

The produced concentrated brine undergoes chemical precipitation and ion exchange to remove impurities like calcium, boron, and magnesium. The purified brine will undergo a vapour recompression evaporation resulting in a concentrated lithium solution with condensate.

Subsequently, the solution will pass through ion exchange 2 to remove calcium, magnesium, and boron in the evaporation or crystallisation process.

Lithium carbonate is obtained through carbonation by using soda ash, while mother liquor would be neutralised with sulphuric acid to remove carbonates.

The product will be dried and reduced in size and then it will be packaged for export.

Key Contractors

The PFS for the project was prepared by engineering consultant Ausenco Chile, Ausenco Sustainability and EL Montgomery & Associates, and Montgomery & Associates Consultores Limitada (M&A).

AUSENCO Engineering was selected to co-ordinate and produce the Preliminary Economic Assessment (PEA) report.

MINERÍA POSITIVA SRL (MP+) conducted bench test on selective adsorption of lithium.

Andina Perforaciones, a construction company based in Argentina, acted as the drilling contractor for August 2021 drilling programme.

In May and June 2018, South American exploration and surveying company Geophysical Exploration & Consulting (GEC) conducted a Controlled-source Audio Frequency Mangneto-Telluric (CSAMT) exploration survey on the project site. The survey consisted of 122 stations.

Conhidro, a Romanian construction and real estate builder, conducted a Vertical Electrical Sound (VES) geophysical survey in Q1 2017 at the project site.