Black Pine Oxide Gold project in Idaho, the US, is being developed by open pit oxide deposit developer Liberty Gold as its flagship project.

A heap leach gold mine at the site operated from 1991 through 1998. During this period, the mine produced 435,000 ounces of gold at a grade of 0.7 grams per tonne (g/t).

Liberty Gold acquired the Black Pine Property from Western Pacific Resource Corporation in June 2016.

Subsequently, the company compiled an extensive drill database, a 3D model of the mineralisation in historic drill holes, and drilled reverse circulation holes.

Drilling activity led to additional discoveries expanding gold mineralisation.

Liberty Gold announced the results of a Preliminary Feasibility Study (PFS) on the project in October 2024.

The study concluded a technically straight-forward, low capital intensity, open-pit, run-of-mine (ROM) heap-leach operation at the property.

It estimated a 17-year mine life with an average annual production of 135 thousand ounces of gold.

Liberty Gold is working to further de-risk the project towards feasibility level. A Mine Plan of Operations is expected to be submitted to the US federal and cooperating agencies in the fourth quarter of 2024.

Black Pine Oxide Gold Project Location

The Black Pine Oxide Gold project is located in Cassia County, southern Idaho. The site is approximately 5 miles south of Juniper and 7 miles west of US Interstate Highway 84.

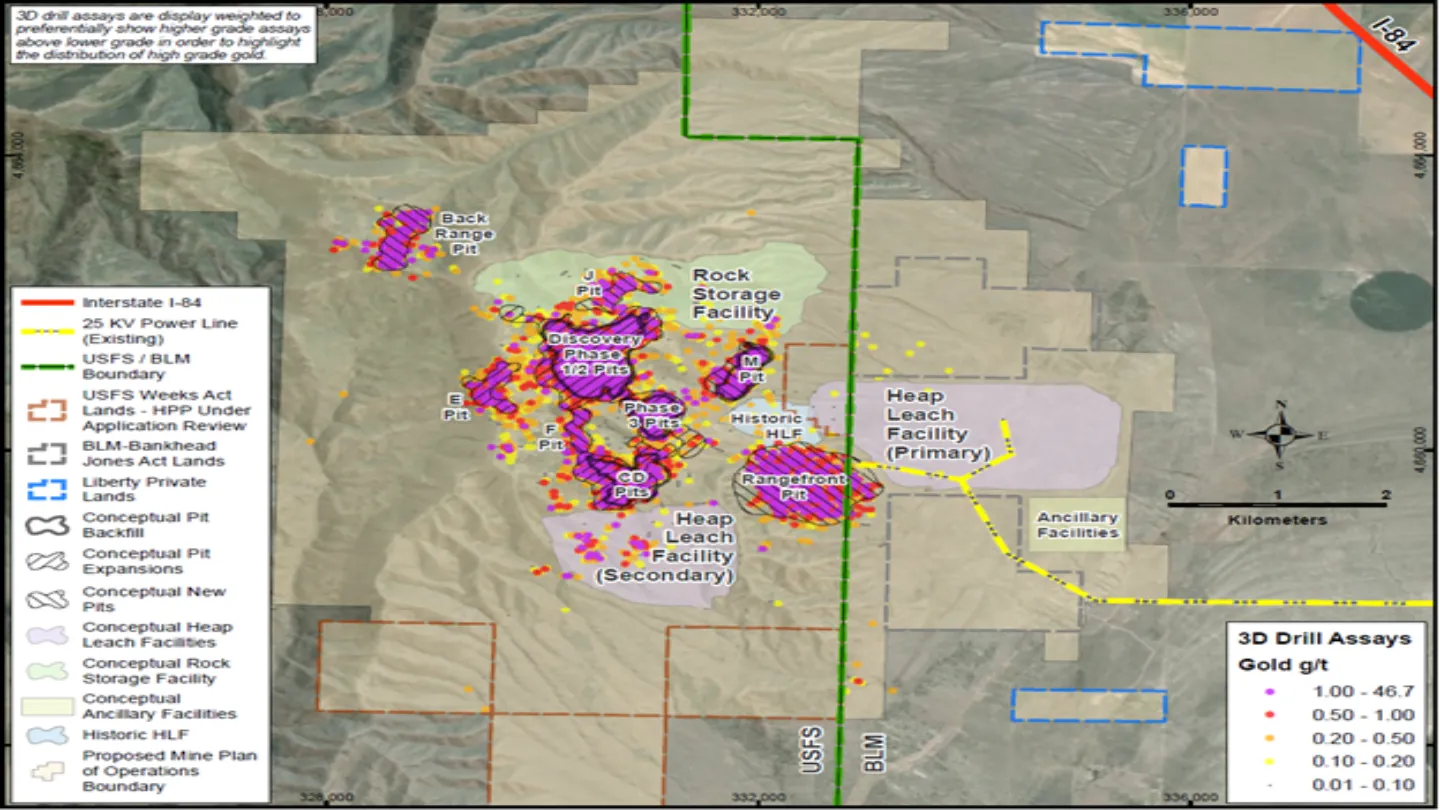

Overall, the project area includes 12,749 acres/ 5,159 ha consisting of unpatented mining claims on US Forest Service (USFS) and Bureau of Land Management (BLM) lands.

Geology and Mineralisation

Black Pine is defined as a Carlin-style, sedimentary rock-hosted gold property. It is located within the southern structural block of the Black Pine Mountains.

The property comprises a lower structural plate of the Devonian Jefferson Formation and Mississippian Manning Canyon Shale; a middle plate consisting of Pennsylvanian carbonate rocks of the Oquirrh Group; and an upper plate primarily including Permian siltstones and sandstones of the Oquirrh Group.

The 200m to 500m thick middle plate hosts the gold mineralisation of interest across an area of nearly 14km2. The highest gold grades are found in calcareous siltstone in proximity to large listric normal faults.

Black Pine Project Mineral Reserves

Mineral Reserves for the gold mine were estimated for a conventional, multiple pit, open pit mining operation.

It is estimated to contain probable reserves of 299.4Mt at a grading of 0.32g/t gold (Au). Contained metal is estimated to be 3,110koz Au.

The PFS also updated the Black Pine Mineral Resource estimate.

The resource is reported at a cut-off grade (COG) of 0.2 g/t Au and consists of indicated resources of 3.2 million oz Au at an average grade of 0.49 g/t Au totalling 203.8Mt.

Inferred resources stand at 325,000oz Au at an average grade of 0.42 g/t Au and totals 24.1Mt.

Mining at Black Pine Project

The PFS anticipates a conventional, multiple pit, open pit surface mining operation that would involve utilising surface waste rock storage facilities, pits backfill, extensive ore stockpiling and direct haul to a single ROM heap leach facility.

The owner will be responsible for planning and executing direct mining activity, while blasting will be carried out by a contractor.

Key mining fleet will comprise 400 tonne-class hydraulic excavators, 100 tonne-class hydraulic excavators, 11.5 cubic metre bucket front end loaders, 136 tonne off-highway haul trucks and 64 tonne off-highway haul trucks.

Around 50,000 tonnes of ore per day or 18.3 million tonnes per year will be fed for the estimated 17-year life of mine.

Primarily, ore will be extracted from two large multi-phase open pits and six smaller ‘satellite’ open pits.

Initially, higher grade ore horizons will be accessed, while lower-grades will be stockpiled throughout the mine life and re-handled on to the heap to optimise gold production.

Processing

At Black Pine, the haul trucks will carry the ore material piling onto a single heap leach pad situated at the eastern extent of the project.

The pad will have four phases to contain up to 315 million dry tonnes of leachable material.

ROM-sized ore will be stacked in 10m vertical lifts to a maximum heap height of 100m. Subsequently, it will be leached with dilute cyanide solution.

A three-train, activated carbon adsorption circuit will be used to recover leached gold.

Any carbon recovered in the gold, and any silver present, will be separated using a desorption process followed by electrowinning to produce a precipitate sludge.

A furnace on site will refine it to produce final doré bars.

The Black Pine Oxide Gold Project will receive power from an existing 25 kV line to the mine gate.

Processing water will be procured from five existing water wells, situated within 5km of the processing facility.

Key Contractors

The Black Pine Oxide Gold Project PFS was prepared by a team of independent industry experts from SLR Consulting, AGP Mining Consultants, GL Simmons Consultants, NewFields Consultants, M3 Engineering & Technology, Piteau Associates, Knight Piésold, Westland Engineering & Environmental Services.