The Blacksmith Project in Western Australia is planned to be developed as a direct shipping ore (DSO) project. The iron ore project is being developed by its 100% owner Red Hawk Mining.

A scoping study for the project, which was released in October 2023, returned positive results. The scoping study was based on the project’s Delta and Paragon deposits.

It was followed by the announcement of pre-feasibility study (PFS) results in May 2024. The PFS extended the DSO project’s scope to include the updated mineral resource estimate for the Champion and Blackjack deposits.

According to the PFS, the project can deliver five million tonnes per annum (mtpa) of DSO products for over 20 years. The mine is projected to have a life of mine (LOM) of 23 years.

Upfront capital investment is estimated to be A$217m ($139m).

The Blacksmith iron ore project is expected to deliver first ore in the fourth quarter (Q4) of 2025.

Blacksmith Project Location

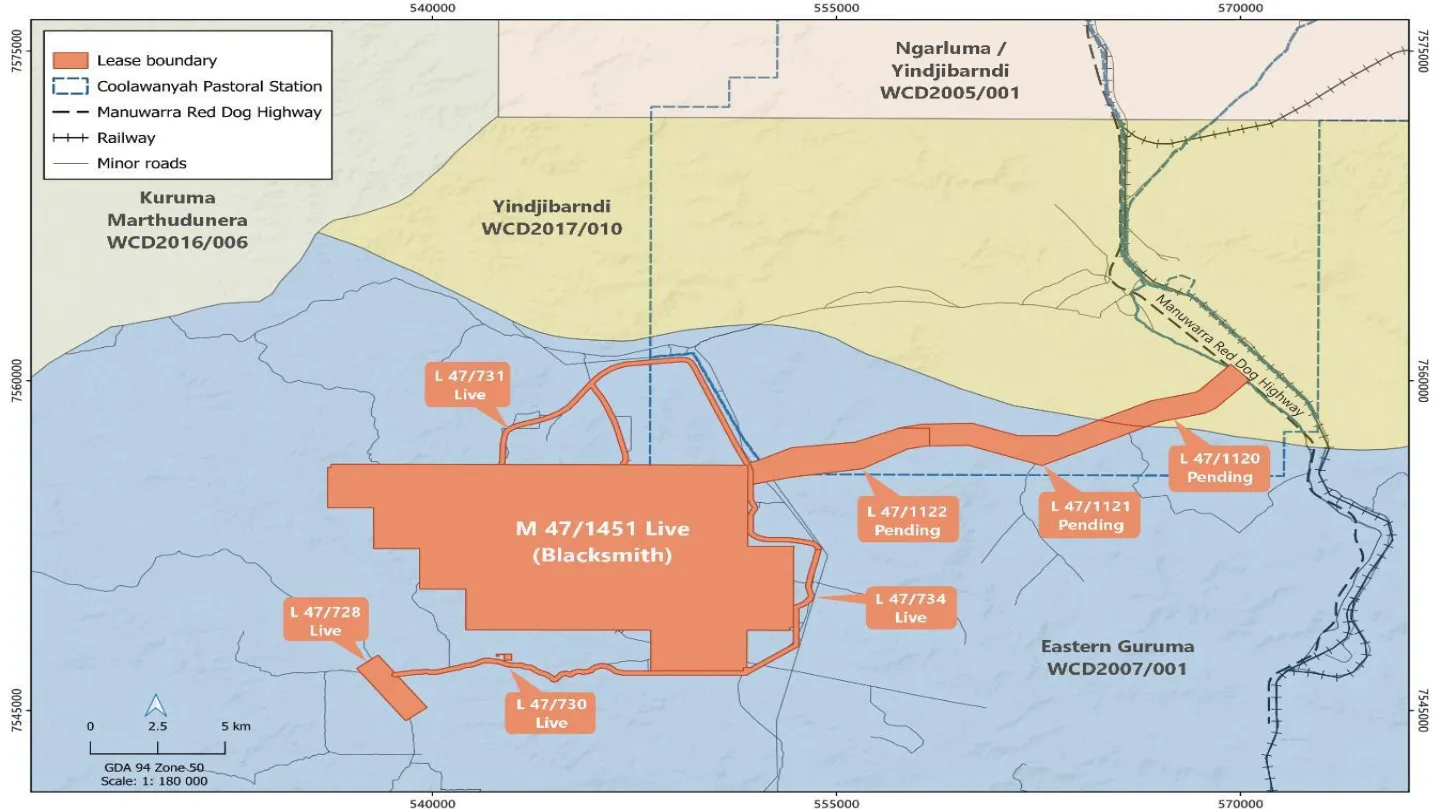

The Blacksmith iron ore project is located in the Hamersley province within the Western Pilbara district of Western Australia.

The location is around 70km north-west of Tom Price and 170km southeast of Karratha.

It lies entirely within Mining Lease M47/1451-I (112km2) and Miscellaneous Licences L47/731 and L47/734. Three additional Miscellaneous Licence applications, L47/1120, L47/1121, were sought for an access road from the site to the Manuwarra Red Dog Highway.

Geology and Mineralisation

The DSO project, surrounded by multiple iron ore projects, is composed of Late Archaean to Palaeo-Proterozoic rocks from the Mount Bruce Supergroup. This includes the Fortescue, Hamersley, and Turee Creek groups, with Wyloo Group remnants over them.

Drilling and exploration activity at the site since 2008 led to the identification of iron ore resources in seven shallow deposits- Ajax, Badger, Blackjack, Champion, Delta, Eagle and Paragon.

The banded iron formation (BIF) units of the Hamersley Group contain the bedded iron deposits of the Pilbara with mineralisation primarily found in the Marra Mamba Iron Formation and Brockman Iron Formation.

The Brockman Iron Formation occurs as an unenriched BIF or as martitegoethite mineralisation within the Dales Gorge Member at Blacksmith.

Mineralisation at the property includes canga (hematite) and Dales Gorge Member hardcap (goethite). The hematite-dominant canga ore has an iron content above 60% Fe.

Blacksmith Project Reserves

Blacksmith project is estimated to contain a probable reserve of 46 million tonnes grading 60.5% iron (Fe). The reserves are located entirely within the Delta deposit and represent 48% of LOM production.

At a cut-off grade of 57.5% Fe, Mineral Resources (Indicated + Inferred) total 173.8Mt grading 60.0% Fe. Around 95% of the resource is classified as Indicated.

Mining and Ore Processing

Although the Blacksmith mining lease includes seven deposits, the PFS considered the development of four deposits – Delta, Paragon, Blackjack and Champion.

Operations will commence in Delta and Paragon and then mining activity will switch to the Blackjack and Champion deposits.

The project will be mined using open-pit method with conventional mining equipment. A mining contractor will be hired for mining operations.

According to the mine plan, the ore reserve of nearly 46 million tonnes will be mined in the first 13 years of the Life of Mine. The bulk of the Indicated, Inferred and Unclassified mineralisation is scheduled from Year 9.

Production will be increased gradually from 1.2Mtpa to 5Mtpa across a five-year period.

The mining activity will involve typical drill / blast / load / haul mining operations. The mining fleet will include two, Cat 6015 excavators and seven to ten Komatsu HD785-7 or Cat 785 haul trucks, besides support vehicles. The combined capacity of the fleet is 16Mtpa.

The run of mine (ROM) ore will be stockpiled to manage the iron grade. The process flowsheet includes primary crushing and screening, followed by closed-circuit secondary and tertiary crushing.

The final product will be stockpiled and then loaded out. DSO will be transported using trucks via a mix of private and public roads to the Utah Point bulk handling facility in the Port of Hedland. From the port, it is expected to be exported to global markets.

Key Infrastructure

Blacksmith Project will use both public and private infrastructure. Mine haul roads will be constructed to support the movement of heavy and light vehicles.

The ROM pad and crushing plant will feature a skyway, a five finger stockpile and a crushing and screening plant.

At Whim Creek, a staging facility will be developed to enable rapid haulage to Utah Point.

The project will procure raw water for operations from borefields at Delta, along the Mine Access Road, and at Badger and Whim Creek Villages.

Red Hawk is also upgrading the water licence to a capacity of 1GL per annum.

Electrical power will be supplied via diesel generators. Crushing plant and villages will be equipped with 500kVA and 750kVA power generators.

Contractors Involved

Ausenco, an engineering, procurement, construction management, and operations service provider, assembled the PFS.

The company provided the process plant, infrastructure, and road intersection designs. It was also responsible for cost estimates, scheduling, risk assessments, and project development plans.

Environmental Resources Management was responsible for geological studies and mineral resource estimates, while FTI Consulting provided financial and economic analysis.

Hypercube Scientific was in charge of haulage simulation modelling.

MGM Bulk and Pastin were hired for transport logistics, while NeoMet Engineering was responsible for providing metallurgical services and marketing.

Orelogy was responsible for the mine planning and ore reserve estimation, and Preston Consulting assisted with the approvals and environmental issues.

SME Geotechnical was responsible for the open pit geotechnical assessment for the project, while Worley, a global engineering company, provided their expertise in hydrology and hydrogeology.

Engineering professional services consulting company WSP was responsible for plant site geotechnical engineering.