The Bonnie Claire Lithium Project is the world’s third largest lithium clay and hard rock deposit located in Nye County, Nevada, USA.

A mineral exploration and development company Nevada Lithium Resources is the 100% owner of the project.

Nevada Lithium published a Preliminary Economic Assessment (PEA) on the project in February 2022.

The PEA outlines 32,300 tonnes of Lithium Carbonate Equivalent (LCE) per year on average and $547m CAPEX inclusive of $126m contingency at a mine life of 40 years.

In October 2024, the owner of the project has awarded contracts to develop the metallurgical processes and plant design for the updated PEA.

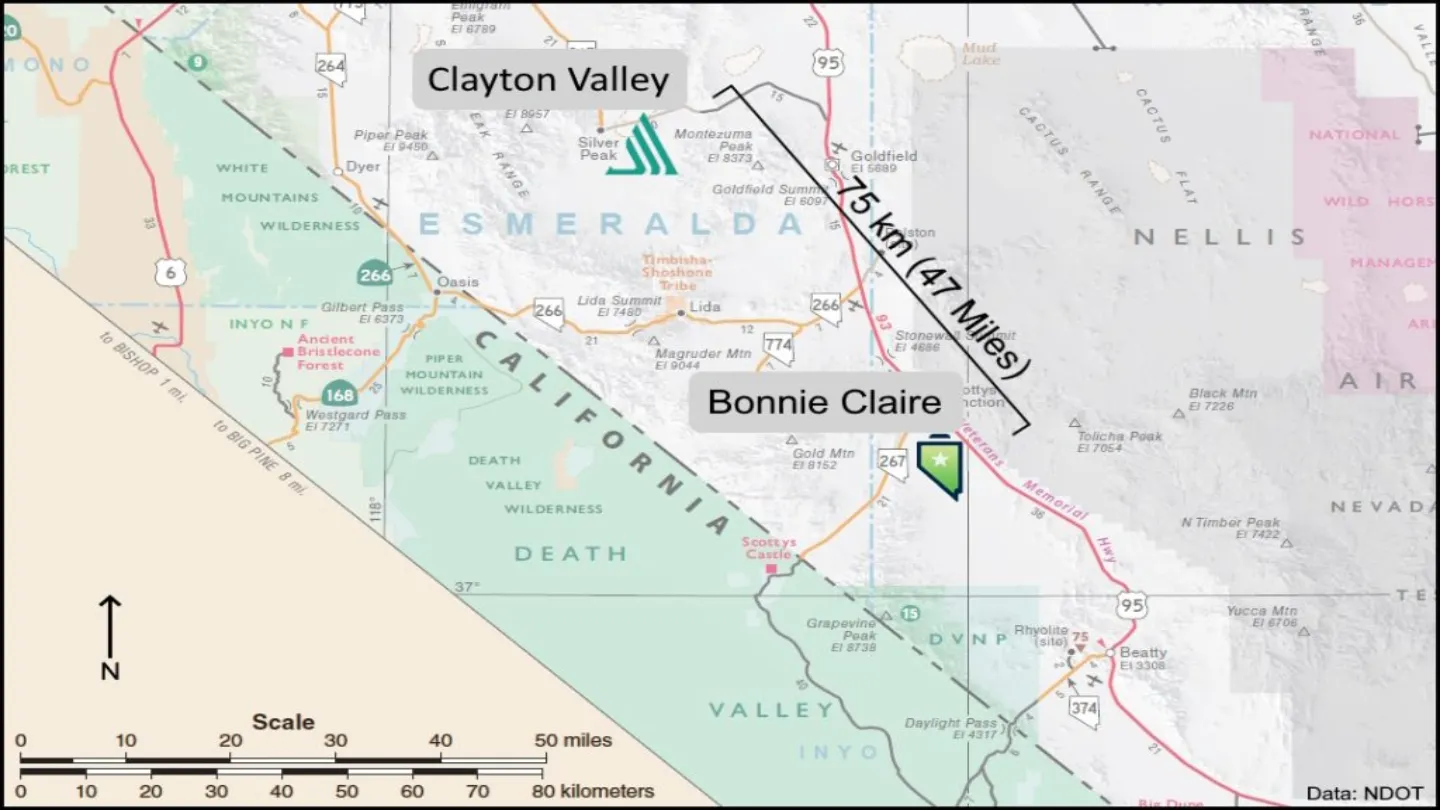

Bonnie Claire Lithium Project Location

Bonnie Claire is located within Sarcobatus Valley. The valley is 30km long and 20km wide.

The project lies 354km southeast of Reno and 201km northwest of Las Vegas.

The project comprises 915 placer mining claims. Each claim covers 8.09 hectares (ha). In total, the claims cover 7405.74ha. The claims are owned 80% by Iconic and 20% by Nevada.

The project is accessible from Las Vegas by taking US-95 N, NV-266 W, and NV-774 S roads and travelling northwest to reach the site.

The project can also be accessed by travelling 40km north on US Highway 95 from Beaty and then travelling 8km southwest on Scotty’s Castle Road.

Ownership Details

Iconic Minerals, owner of lithium and gold exploration projects in Nevada, via its wholly owned subsidiary Bonaventure Nevada signed an option agreement with Nevada Lithium in November 2020.

Under the agreement, Nevada acquired 50% interest in the project.

In January 2023, both companies signed a Letter of Intent (LOI) followed by a definitive arrangement agreement in March 2023.

The arrangement was completed in July 2023 as per which Nevada acquired 100% interest in the project.

Geology and Mineralisation

The closed Bonnie Claire Basin is located near the southwestern edge of the Basin and Range geo-physiographic province of western Nevada.

The main structural element of the Basin and Range is Horst and graben normal faulting.

The topography of the basin consists of flat and elongated quaternary sediments of playa and alluvium.

The Pleistocene period was subjected to multiple wet and dry periods resulting in the formation of lacustrine deposits, salt beds, and lithium brines in the basin.

The diagenetic alteration of the tuffaceous rocks is accompanied by anomalous high lithium concentrations.

The average grade of lithium mineralisation depends upon the host sedimentary layers.

The layers consist of sand or sandstone averaging about 30ppm to 570ppm from near surface to depth, silt or siltstone from 135ppm near surface to 1,270ppm at depth, and clay, mud, claystone, or mudstone from 300ppm near surface to 2,550ppm at depth.

Lithium salts and lithium carbonate at the project are hosted within the fine-grained clay, silt, and sand pore space.

The 2024 metallurgical program identified high-grade lithium and boron mineralisation. Boron mineralisation is hosted in the searlesite mineral.

Bonnie Claire Lithium Project Mining

The PEA evaluated open pit, Bore Hole Mining (BHM), and combination of both for mining the Bonnie Claire Lithium Project.

The most viable option among the two methods is hydraulic BHM (HBHM). For mining, production hole will be drilled at an angle beneath the Lower lithium-rich fine sediments layer.

A jet hole will be drilled vertically to meet the production hole. Through hydraulic BHM, the slurry will drop to the bottom of the well and will be pumped to the surface via the production well.

The water jet will rise slowly, and the slurry will be transported to the processing site.

Processing Details

The slurry in the process plant will enter feed preparation and pretreatment circuit where the slurry would be reduced in size and calcinated to produce soluble lithium sulphate.

The material will undergo leaching, thickening, and filtration. The processes will result in a Pregnant Leach Solution (PLS).

The PLS will be separated from the impurities in a Secondary Impurity Removal (SIR) circuit by addition of soda ash and a 5-stage thermal-mechanical evaporation system.

The resulting filtrate will undergo ion exchange to remove the remaining manganese or calcium from the PLS. The ion exchange resin will react with hydrochloric acid and regenerated with sodium hydroxide.

The purified PLS will enter the product precipitation circuit. The circuit will produce lithium carbonate with 99.5% purity as targeted.

The product will be dried and packed and sealed in 1-tonne bags to be transported to the US manufacturers.

At full operations, the nominal production rate is targeted at 15,000 tonnes per day (tpd) or 5.25 million tonnes per year (Mt/y).

Lithium is estimated to be recovered at 74.7% of lithium tonnes processed. The production will range from 16,500 tonnes per year (tpy) of LCE in the first year to 38,000tpy of LCE in the 17th year.

Boron and lithium will be recovered by a two-stage leaching process comprising a dilute acid leach at 160kg acid per tonne solid to recover boron and a concentrated 500kg acid per tonne solid to recover lithium.

From the above process, a 97% recovery of lithium and a 98% boron recovery is possible as outlined by Hazen, a Colorado-based research and development company.

Project Infrastructure and Power Supply

The infrastructure of Bonnie Claire Lithium comprises the state and county roads, buildings and yards, a processing plant, and a tailings management facility.

The other infrastructural facilities are a water supply facility, a waste management facility, and a storm water handling facility.

The project will receive power by a connection running along the US-95 Highway and connecting the regional grid.

Onsite, the power will be supplied by a main substation located near the processing plant. The electricity will be fed via overhead and buried transmission lines to various portions of the project.

Bonnie Claire Lithium Project Contractors

Fluor Enterprises, a Texas-based engineering and construction firm, will develop the metallurgical processes and the process plant for the updated PEA on the project. The contract was awarded in October 2024.

In October 2024, Kemetco Research, a researcher in specialty analytical chemistry, chemical process and extractive metallurgy, will coordinate the test work program in the testing of material at its lab facility.

The preliminary acid leach benchwork and the design of a conceptual acid treatment process to recover lithium and boron were conducted by Hazen.

Power One Capital Markets, a Toronto-based investment bank, with other companies will be the finder in $6m private placement to Nevada Lithium.

A Kansas-based consultant Kinley Exploration assessed the HBHM mining method for the project in April 2024 and provided a working model based on HBHM.

Hazen also produced battery-grade lithium carbonate in February 2023. Hasbrouck Geophysics conducted seismic survey on the project site. The survey was completed in January 2024.

The project site was subjected to a seismic reflection survey conducted by Hasbrouck Geophysics, Matrix Surveys, Columbia Geophysical, and Bird Seismic Services. The survey commenced in October 2023.

The PEA of the Bonnie Claire Lithium Project was prepared by Global Resource Engineering, a mining engineering firm.