Cabaçal is an advanced stage copper-gold project being developed by UK-based development mining company Meridian Mining UK S. The project is located in the State of Mato Grosso in Brazil.

In March 2023, the company announced the positive results of the Preliminary Economic Assessment (PEA) for the Cabaçal gold-copper deposit. This was followed by the completion of a Preliminary Feasibility Study (PFS) in March 2025.

According to the PFS study, Cabaçal can deliver 141,000 gold equivalent (AuEq) ounces in average annual production over ten years. Production may average 178,000 AuEq ounces annually in the first five years.

Life of Mine (LOM) silver and copper production are expected to total 1.3 million ounces and 169.65 tonnes, respectively.

Initial capital expenditure is estimated to be $248m.

A detailed feasibility study on Cabaçal Copper-Gold Project will commence soon, with plans to conclude it during the first half of 2026.

Cabaçal Project Location

The Cabaçal Gold-Copper Project is located in the State of Mato Grosso with mining rights straddling across five municipalities. The gold‐copper‐silver rich volcanogenic massive sulphide (VMS) deposit has the potential to become the standalone mine within the 50km VMS belt.

The site is approximately 310km from the state capital Cuiabá.

Geology and Mineralisation

The Cabaçal and Santa Helena deposits, along with other identified targets, are associated with a Paleoproterozoic volcanogenic massive sulphide (VMS) system featuring stringer and disseminated sulphide mineralisation. This system is hosted within deformed metavolcanic-sedimentary rocks of the Alto Jaurú Greenstone Belt.

The geological package consists of a bimodal volcanic sequence, comparable to those found in major VMS districts. Regionally, the Cabaçal host sequence is believed to be situated on the overturned eastern limb of an east-verging anticline.

Mineralisation includes massive, stockwork/breccia-style, stringer, and disseminated sulphides, primarily composed of chalcopyrite, with lesser amounts of pyrite and sphalerite. The deposit also has a relatively high gold content, which has been enriched by a later-stage hydrothermal overprint affecting the original VMS system. Mine development has revealed both shallow-dipping and steeper-dipping late-stage vein sets.

VMS systems often form clusters of deposits, offering exploration potential both near existing mines and in wider regional targets.

Mineral Reserves Estimate

Cabaçal contains proven and probable mineral reserves of 41.7Mt at 0.63g/t Au, 0.44% Cu and 1.64g/t Ag declared, containing 849.88koz of Au, 405.38Mlbs of Cu and 2,194.41koz of Ag.

Measured and indicated mineral resources total 51.43Mt at 0.55g/t Au, 0.40% Cu and 1.50g/t Ag for open pit mining and Inferred resources of 0.96Mt at 0.96g/t Au, 0.49% Cu & 1.36g/t Ag for underground mining.

Mining and Processing

The proposed Cabaçal mining operation is a 10.6-year, shallow open-pit project with a total feed inventory of 41.70Mt. In its first year, the mill feed will contain high-grade ore averaging 1.45 g/t gold and 0.54% copper, with a life-of-mine (LOM) average grade of 0.63 g/t gold, 0.44% copper, and 1.64 g/t silver.

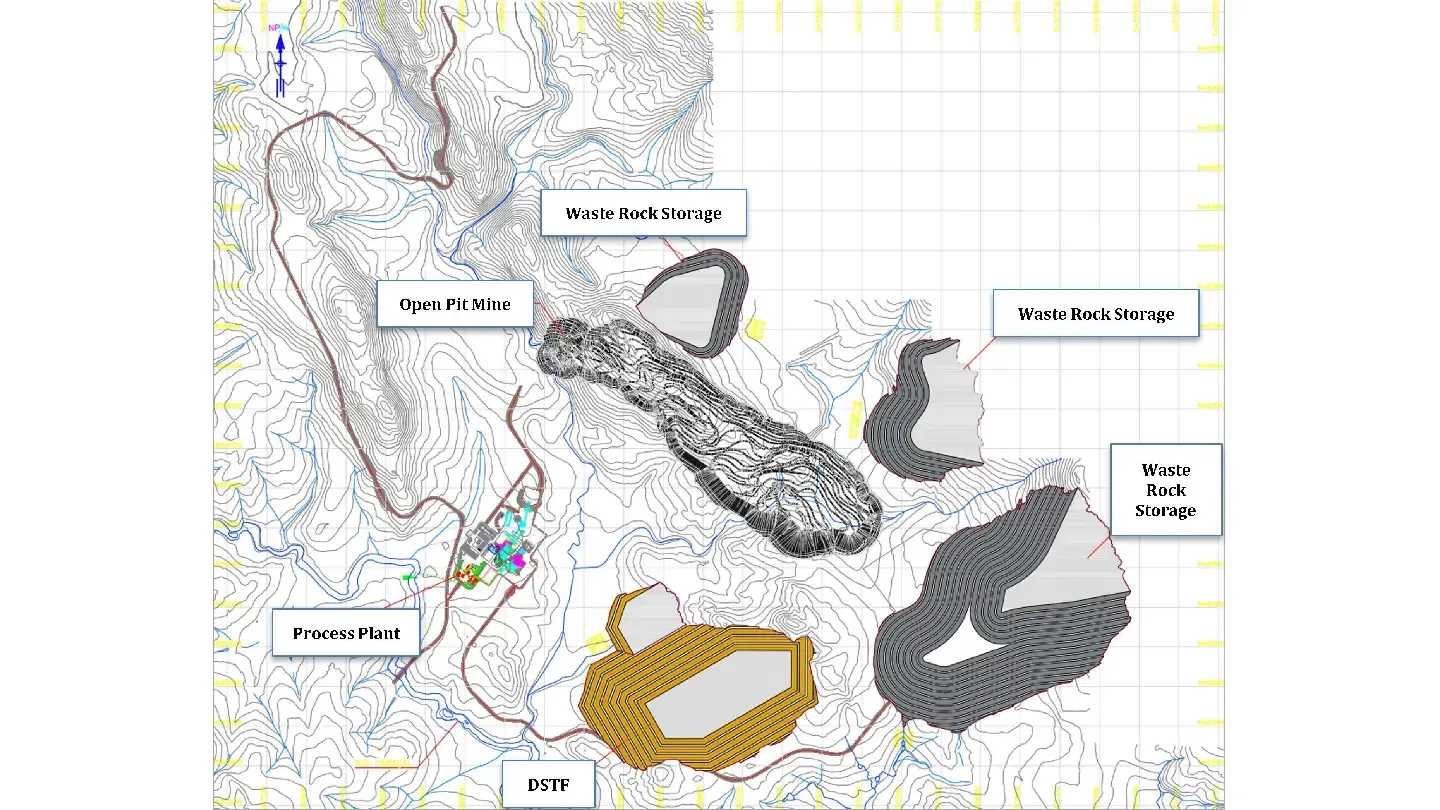

Mining will be conducted using an open-pit method with ore production designed to support a processing plant with an initial capacity of 2.50Mtpa for the first three years, increasing to 4.50 Mtpa for the remaining 7.6 years.

The operation will use a block model with dimensions of 10x10x5m and a slope angle of 54° inter-ramp for fresh rock in the hanging wall, while the footwall will follow the slope of the mineralised material. Mining activities, including mechanical blasting, loading, and haulage, will be fully outsourced.

The ore is relatively soft, with an average Bond ball mill work index of 11.8, and will require blasting at a load ratio of 200 g/t for mineralised material and 155 g/t for waste. Transport distances from the pit to the RoM yard will range from 1.58km during pre-stripping to a peak of 1.98km in Year eight, while waste transport distances will extend from 1.96km to 2.61km in Year ten.

Ore and waste transport will utilise 55-tonne trucks with operations supported by 74-tonne hydraulic excavator. Ore will be transported either directly to the crusher or to the RoM stockpile, from which a 30.3-tonne wheel loader will reclaim material as needed. Waste will be transported to three designated dumps.

The Cabaçal project will produce two primary saleable products: gold and silver in doré bars and a copper-gold concentrate.

Process plant design, based on SGS test work and developed by Ausenco, will initially handle 2.5Mtpa of RoM feed, increasing to 4.5Mtpa from the fourth year. The processing circuit includes crushing and grinding to achieve a primary grind of 80% passing 200 microns. Around 30% of the mill feed will be directed to a gravity separation circuit for free gold recovery, with the gravity tailings recycled back to the grinding circuit.

The ground material will then undergo copper flotation in conventional cells, with the rougher concentrate reground and cleaned in a Jameson cell to produce the final concentrate. Copper flotation tailings will be processed separately to generate a pyrite/high-sulphide concentrate and a low-sulphide tailings stream, which will be filtered and disposed of accordingly.

Infrastructure

Cabaçal benefits from well-developed public infrastructure. The site is accessible via sealed roads from the state capital of Cuiabá, followed by a 35km all-weather gravel road from the company’s administrative base in São José dos Quatro Marcos.

The region is currently serviced by a 34.5kV high-voltage power line, with multiple hydroelectric power stations operating nearby. A proposed 138kV transmission line route has been identified, spanning 22km from the Araputanga substation to the project site, which would provide sufficient capacity for the mine’s operations.

Water supply for the project is expected to come from the nearby Cabaçal River, subject to permissions.

The process facility will be designed to maximise water recovery and reuse, minimising external water demand. Additionally, all rainwater that interacts with mining activities will be collected and either reused on-site or treated to meet regulatory standards before being discharged.

Contractors Involved

The Cabaçal Project’s Preliminary Feasibility Study (PFS) was led by Ausenco do Brasil Engenharia and Ausenco Engineering Canada, supported by GE 21 Mineral Consultants.

Ausenco also prepared the Preliminary Economic Assessment (PEA) for the copper-gold project.