The Coka Rakita project is a gold discovery located in Serbia. The project is being developed by Canada-based gold mining company Dundee Precious Metals (DPM).

The preliminary economic assessment (PEA) for the gold mine was completed in April 2024. This was followed by the announcement of the results of a pre-feasibility study (PFS) in December 2024.

According to the PFS, the development of the Čoka Rakita project will entail an initial capital investment of $379m.

With a life of mine (LOM) of ten years, the project is estimated to produce 170,000 ounces (oz) of gold in the first five years.

DPM is proceeding with permitting activities and the feasibility study, which is expected to be completed by the end of 2025.

Construction works at Coka Rakita may begin in mid-2026, supporting first concentrate production in 2028.

Coka Rakita Project Location

The Coka Rakita Project is located in the eastern part of the Republic of Serbia, around 25km north-west from the town of Bor. DPM’s Timok gold project is around 3km from the site.

The site includes one exploration licence with an area of 14km². It can be accessed by regional asphalt roads and well-developed unpaved forestry roads.

Geology and Mineralisation

The Coka Rakita Project is situated within the north-western part of the Timok Magmatic Complex (TMC), a part of the Western Tethyan Belt segment.

TMC includes multiple fault populations of different inferred ages-of-formation. It stretches 85km extending from the town of Majdanpek in the north to the village of Bučje in the south.

In the region, the oldest outcropping rocks are Palaeozoic phyllites composed of sandstone, shale, and conglomerate protolith.

Two interpretative carbonate units were defined within the larger project area. They are Upper Jurassic (JLS) and Lower Cretaceous (KLS). The older Jurassic age features massive limestone, while the lower parts are made of micritic limestone with concretional chert nodules.

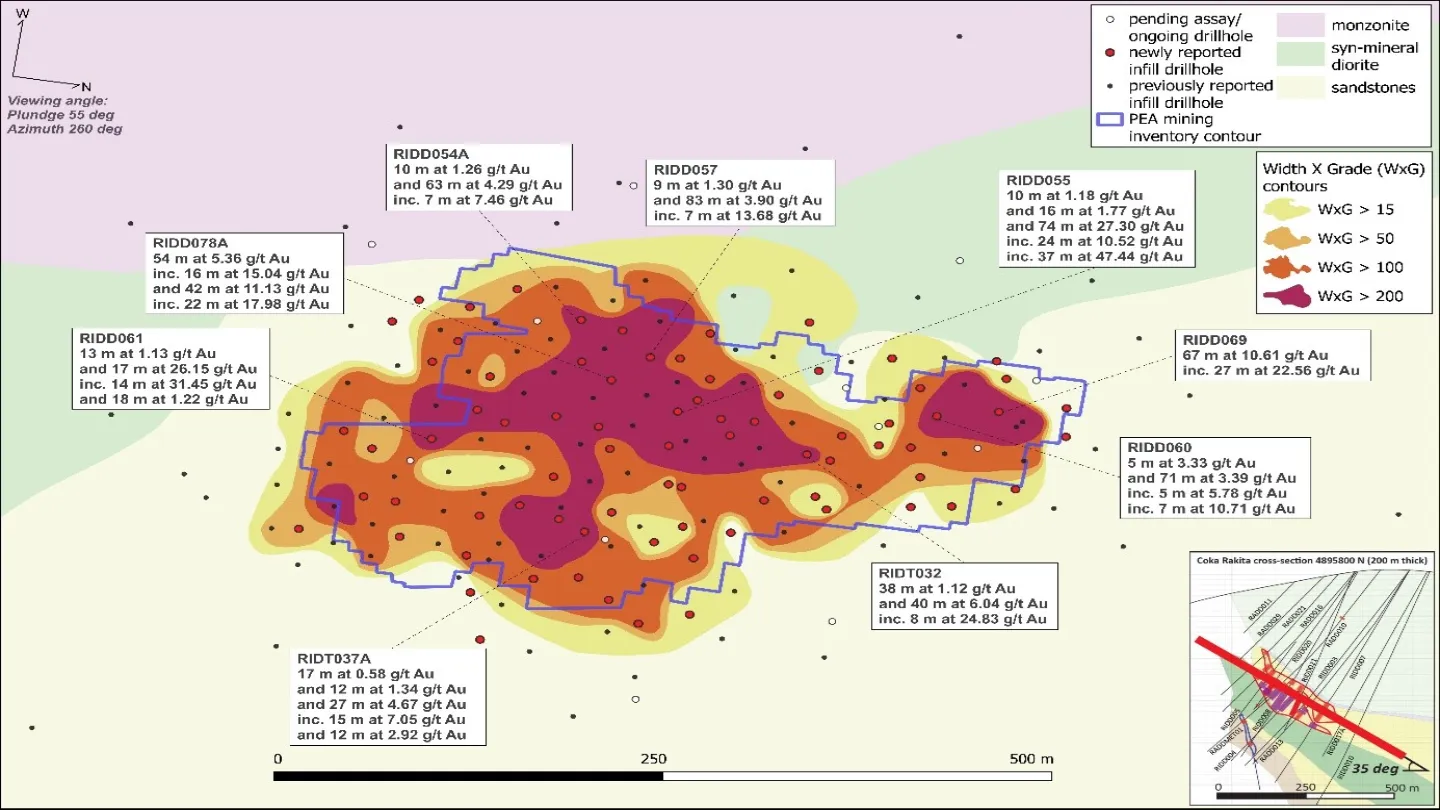

The gold-rich skarn mineralisation occurs within carbonate-rich sandstones and conglomerates. It formed a shallow-dipping tabular mineralised body situated 250m and 450m beneath the surface.

The body is around 650m long and up to 350m wide, with a thickness ranging between less than 20m in the margins to more than 100m in the core of the mineralised zone.

Areas of intense retrograde skarn alternation also contain some coarse gold.

Coka Rakita Project Reserves

According to the PFS, the Coka Rakita project is estimated to contain proven and probable mineral reserves of 6.6 million tonnes (Mt) at 6.38 grams per tonne (g/t) for 1.36 million contained gold ounces.

Total Measured and Indicated Mineral resource, exclusive of Mineral Reserves, is estimated to be 1.45Mt at 3.30g/t for 154Koz of contained gold.

Mining and Ore Processing

The PFS outlined underground mining at Čoka Rakita deposit with a relatively standard flowsheet to process 850,000 tonnes of ore per year.

The plan includes accessing the deposit from surface via two declines and a spiral ramp.

A conventional sublevel long-hole open stoping method will be used for mining. This includes utilising paste backfill with cemented rock fill, and unconsolidated rock fill where the mining sequence allows.

In the initial years, mining activity will target high-grade mineralisation with production expected to average 170,000 ounces annually from an average gold head grade of 7.42 g/t in the first five years.

The average life of mine (LOM) gold production is expected to be approximately 147,000 ounces per year from an average gold head grade of 6.38 g/t.

The PFS incorporates a processing flowsheet that includes crushing and grinding to achieve a particle size (P80) of 53 µm.

This will be followed by gravity concentration and sulphide flotation.

The gravity concentrate will be directly marketable to gold refineries, while the sulphide flotation concentrate will be sent to regional smelters.

A portion of the gravity concentrate will be refined into doré bars for sale.

Payability is estimated at 97.5% for the flotation concentrate, 99.8% for the gravity concentrate, and 99.9% for doré, resulting in a combined life-of-mine weighted average payability of 98.5%.

Power Supply

The project will explore technical and economic feasibility of two choices of connecting to the national electrical grid.

The first option involves constructing a 35kV line from Zagubita city where the substation will be expanded to accommodate additional equipment. The second option is to build a 110kV line from the city of Bor.

Coka Rakita Project will also have two diesel generation plants, with an effective capacity of 1.6MW each, which will provide power during emergencies.

Contractors Involved

The Coka Rakita Project PEA report was prepared by DRA Americas, an engineering and consulting company. It was responsible for reviewing metallurgical test work, developing design criteria, and recovery methods, and overseeing the process plant and related infrastructure.

The company was supported by Environmental Resources Management, Responsible Mining Solutions, SLR Consulting and WSP Global.

Environmental Resources Management developed the mineral resource estimate, and conducted environmental studies, secured permits, and assessed social impacts.

Responsible Mining Solutions offered the design of the paste backfill system, while SLR Consulting was responsible for designing tailings management and waste rock facilities, and a site-wide water balance.

WSP Global delivered the underground mine design and associated infrastructure.

The PFS was prepared in accordance with the Canadian regulatory requirements, and was reviewed by personnel from Environmental Resources Management, DRA Americas and WSP Global among others.