The Fenelon gold project is an underground mine located in the Quebec province of Ontario, Canada. Wallbridge Mining, the owner and developer of the mine, purchased it from Balmoral Resources.

Wallbridge Mining is currently carrying out a 35,000t bulk sampling and exploration programme at the mine. Production decision on the project is expected to be taken based on the bulk sampling results in 2019.

The gold mine is expected to produce 400 tonnes per day (tpd) over its initial mine life of a minimum of one to two years.

Fenelon gold project geology and mineralisation

The Fenelon project property covers an area of 1,052ha in the Sunday/Detour Lake Deformation Zone (SLDZ) area in the Quebec province.

The mine area is located in the Harricana-Turgeon volcano-sedimentary segment, which extends from the Detour Lake mine of Ontario in the west to Matagami. It is also a part of the famed Abitibi sub-province of the Canadian Shield.

Gold mineralisation is hosted in the silicified envelopes containing sulphides such as pyrrhotite, chalcopyrite and pyrite. The sulphides are hosted in quartz veins with pyrrhotite being the dominant sulphide.

Mineral reserves at Fenelon gold project

Fenelon is estimated to contain proven and probable reserves of 96,720t graded at 9.3g/t of Au.

Mining and ore processing

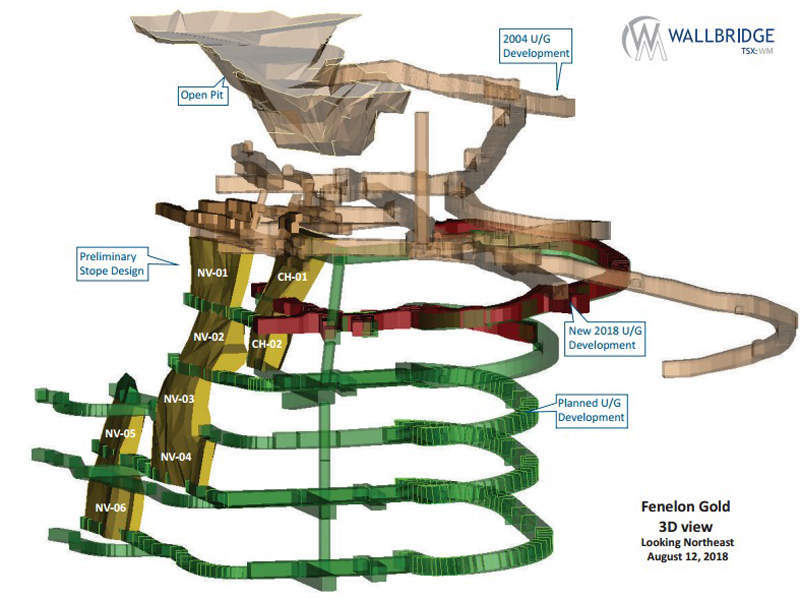

A combination of longhole open stoping method, uppers longhole open stoping method, and drift and fill mining method will be used to mine the ore at Fenelon. Drill and fill mining method will be practiced in areas where the ore body does not allow for the longhole or uppers method.

Ore will be mined using a fleet of boom jumbos for ramp, sill and level access development, five and three yard scoops for production mucking and backfilling and boom trucks.

Ore will be processed at the Camflo mill situated new Malartic town area. The ore first undergoes primary crushing in a cone crusher. The overflow from the primary crusher is fed to the secondary crushing circuit comprising two ball mills.

“Fenelon gold mine is estimated to contain proven and probable reserves of 96,720t graded at 9.3g/t of Au.”

The underflow is sent for further grinding, while the overflow is fed to three thickeners. The overflow from the thickeners is fed to a leaching circuit, which has six tanks with a capacity of 400m³ each.

The leached solution undergoes three washing stages to produce a gold rich pregnant solution. Gold is recovered through the Merrill Crowe process and melted in Wabi furnaces to produce doré bars.

Infrastructure at Fenelon gold project

The mine can be accessed through the 109 Highway from Amos. The Tembec forestry located approximately 21km from the highway junction also provides access to the mine.

Two diesel generator sets are planned to be installed to provide power supply to the mine. The first unit will power the office, dry, kitchen, garage and rooms, while the second unit will supply power to mine ventilation, dewatering systems and underground equipment.

Process water will be sourced from a well located on the site. Water can also be recovered from the polishing pond or the surface sump.

An office building, cafeteria and accommodation facility, ore and waste handling crusher will be constructed on the site.

Contractors involved

Monarques Gold Corporation was awarded a custom milling contract for the exploration programme in November 2017.

WSP Canada, InnovExplo and SNC-Lavalin were involved in preparing the technical report for the project.