The Fenix lithium mine is an integrated brine extraction and lithium processing facility located in the Salar del Hombre Muerto salt pan in Argentina.

The mining concession is owned and operated by Minera del Altiplano, a local Argentinian operating subsidiary of Philadelphia-based chemical manufacturing company Livent.

The Fenix lithium mine was previously under the ownership of FMC Corporation until Livent was separated from it through a spin-off in March 2019.

Commercial lithium extraction was started with the opening of a lithium carbonate manufacturing facility in Fenix and a lithium chloride manufacturing facility in Guemes in 1998.

The manufacturing facilities, both operated by Minera del Altiplano, produced approximately 17,000t lithium carbonate and 4,000t of lithium chloride in 2019.

The total production capacity is expected to increase up to 40,000t from 2022 onwards as part of a mine expansion which is currently in the planning stage.

Project location geology

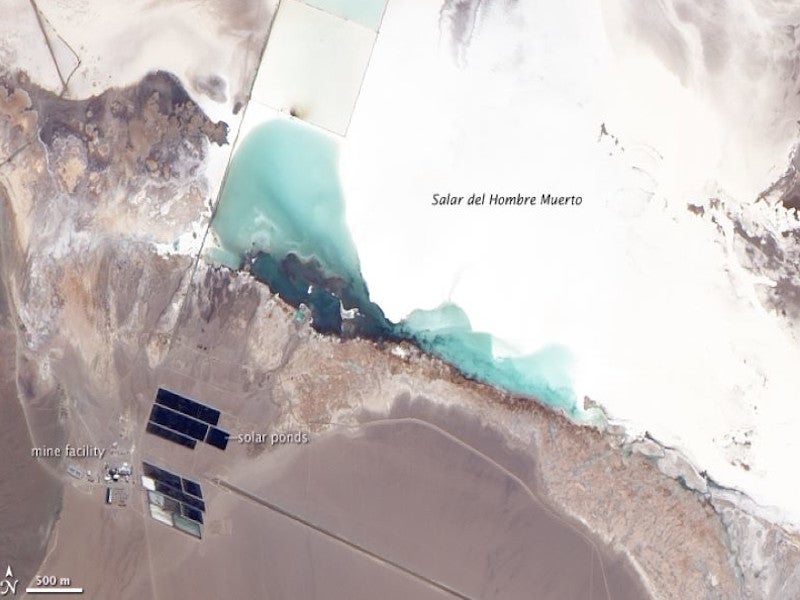

The Fenix lithium mine is located in the western section of the Salar del Hombre Muerto salt flat in the province of Catamarca, Argentina.

Located at an elevation of 4000 metres above the sea level (masl), the Salar del Hombre Muerto covers an area of approximately 600 km2 and forms a part of the Lithium Triangle which is a lithium-rich region of the Andes around the borders of Argentina, Bolivia and Chile.

Geological investigations of the Salar del Hombre Muerto salt bed involving the drilling of 20 diamond wells were carried out from 1990 to 1995. The exploration studies discovered sufficient recoverable brine reserves within a depth range of 40m to 70m to support a long-life commercial operation.

The Salar del Hombre Muerto salt flat is an evaporite deposit divided into two separate sub-basins. Borate evaporites dominate the eastern sub-basin while the relatively clastic sediment-free western sub-basin is dominated by halite evaporite deposits.

The mineral concession rights for the Fenix Lithium mining operations cover an area of approximately 327 km2.

Lithium reserves at Fenix

The Fenix lithium mining concession on the Salar del Hombre Muerto flat was estimated to hold recoverable reserves of up to 1.2 million tonnes (Mt) of lithium carbonate equivalent (LCE) as of March 2019.

Mining and processing operations

The mining operations at the Salar del Hombre Muerto salt flat uses the pumping-evaporation method which involves pumping of brine from underground saltwater aquifers with the use of extraction wells.

The pumped brine contains approximately 600 parts per million (ppm) of lithium. The brine solution is then transferred to an evaporation pond system through a network of pipelines.

The brine undergoes lithium concentration and purification in the evaporation pond to remove other minerals such as sodium, potassium, and magnesium. The resulting lithium chloride brine is pumped from the terminal pond of the system and routed to the off-site processing plant at Fenix where lithium carbonate is extracted.

The brine extract from the Fenix processing facility is then transported by road to the Guemes processing facility for the production of lithium chloride. The processed lithium carbonate and lithium chloride are then transported by trucks to ports in Argentina and Chile for shipping.

Infrastructure facilities

The Fenix lithium mine is accessible via local roadways from the city of Salta. A 3km-long airstrip is also located at the Fénix mine camp.

Livent has water rights to extract fresh water from the Trapiche which is done with the use of battery-powered wells. The wells also supply water to the processing facilities.

A 135 km long natural gas pipeline from Pocitos was completed in 2015 to supply gas for the Fenix facilities.