The Fort Cady borate project is a boric acid (H3BO3) deposit located in California, US. American Pacific Borate and Lithium (ABR) is developing the highly rare and large colemanite deposit with a capital expenditure of £401m ($526m).

ABR is just the third player to develop one of the world’s biggest known contained borate occurrences, apart from Rio Tinto and Eti Maden.

Definitive feasibility study (DFS) of the borate project was completed in December 2018, while an enhancement report for the DFS was completed in January 2019. The mine life of the Fort Cady borate project is 21 years.

Project development

The project is planned to be developed in three phases, with the first phase operations further divided into two phases – 1A (starter project) and 1B.

Construction of the first phase will be started in the fourth quarter of 2019, with production planned to be started in the fourth quarter of 2020.

Phase 1A will target the production of 40,000 short tons per annum (stpa) of SOP (potassium sulphate or K2SO4) and 6,000stpa of H3BO3. Boric acid production will be increased to 90,000stpa under Phase 1B.

The second and third phases will produce a total of 163 million metric tons (Mmt) of boric acid and 36.3Mmt of SoP each. Production from the two phases will be commenced in the second quarter of 2023 and 2025, respectively.

Fort Cady borate project location, geology, and mineralisation

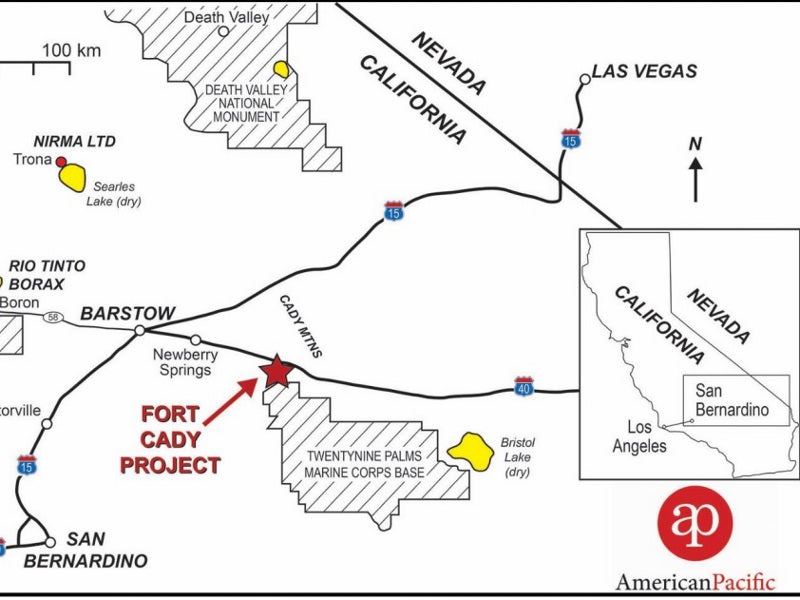

The Fort Cady borate project is situated in the eastern side of the Mojave Desert region, which is located in San Bernardio County, California, US. The site is situated approximately 200km to the north-east of Los Angeles near the Newberry Springs town and the city of Bastow is at a distance of 50km.

The borate project extends in 1.39 square kilometres (km2) including 1.1km2 of ore body well field. The project hosts the recently formed olivine basalt flows from Pisgah Crater, situated 3.2km from the site.

The main borate deposit at Fort Cady area is located between 350m and 450m beneath the surface and comprises sequence of mudstone and tuff. The borate mineralisation takes the form of colemanite and majorly found in thinly laminated silt, clay, and gypsum beds.

Ore reserves

The total amount of reserves in the project is 41.01Mmt with boron trioxide (B2O3) grading 6.6% and H3BO3 grading 11.72%. It is estimated to contain 367ppm of lithium, 2.71Mt of B2O3, and 4.81Mt of H3BO3.

The measured, indicated, and inferred mineral resources are estimated to be 120.44Mmt, grading 6.51% of boron trioxide and 11.57% of boric acid.

Mining and ore processing at Fort Cady borate project

The Fort Cady project will apply solution mine/in-situ solution mining method as the ore body contains vertical impermeable layers. The field will initially operate on the ‘push and pull’ method until the wells connect naturally, following which ore will be recovered using separate recovery and injection wells.

HCl solution will be injected underground into the colemanite orebody, where it will leach the colemanite ore to produce a pregnant leach solution (PLS). The PLS will be used to convert the colemanite into boric acid.

The PLS from the production wells will be taken to the surface where the boric acid will be separated from impurities by solvent extraction (SX), concentration, and cooling crystallisation processes. The crystallised boric acid will be dried, sized, and bagged as final product.

Acidification of the process waste stream with sulphuric acid (H2SO4) will result in the regeneration of HCl, within the boric acid plant. The process also results in gypsum crystallisation.

The sulphate of potash (SOP, potassium sulphate) plant processes muriate of potash (MOP, potassium chloride) with Mannheim furnaces to produce high-quality SOP. The production of SOP yields HCl as a by-product and further used in solution mine ore extraction.

Infrastructure

Access to the Fort Cady borate project is through the I-40 Hector turn-off connecting to Route 66.

A 1.8km-long pipe located between the processing plant and the existing Pacific Gas and Electric Company (PG&E) main line will supply natural gas for the project.

Water will be collected from the two existing water wells, while four new wells are proposed.

American Pacific Borate proposes to source power from internal power generation sources (Cogen). The steam turbine type generator will generate approximately 8MW of power from the steam generated by the natural gas-fired boiler.

Contractors involved

Barr Engineering prepared the DFS for the Fort Cady borate project and participated in preparing the mineral processing programme of the deposit.

American Pacific Borate awarded the contract to prepare a detailed mining plan for Fort Candy to Piteau Associates, while RESPEC Consulting converted the identified mineral resource estimates to ore reserves.

Millcreek Engineering, a company based in Utah, was engaged to conduct basic engineering for the project.