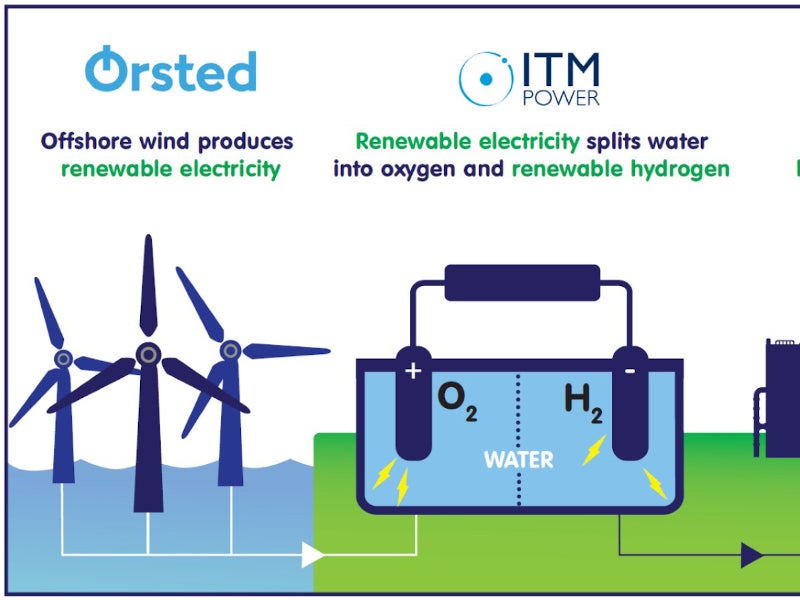

Gigastack is a demonstration project in the UK for industrial scale, low-cost renewable hydrogen production through the electrolysis process.

The innovative project is being undertaken by a consortium led by ITM Power, an electrolyser systems manufacturer based in Sheffield, UK, while the other partners are wind power producer Orsted, oil refining company Phillips 66, and low-carbon energy consultant Element Energy.

The design of a 5MW electrolyser stack was developed and an initial feasibility study was completed as part of phase one of the project in September 2019.

The project advanced to phase two after securing funding from the UK Government in February 2020.

UK Government funding for Gigastack

The Gigastack consortium partners received £7.5m ($10m) funding from the Department for Business, Energy and Industrial Strategy (BEIS), Government of the UK, in February 2020.

Gigastack was one of the five demonstration phase projects related to bulk hydrogen production and supply in the country that received financial assistance from the BEIS innovation fund, as part of the £90m ($115m) package in support of UK’s 2050 net-zero greenhouse gas emission target.

The project had also received a funding of £499,905 from the UK government for conducting a feasibility study during phase one in 2019.

Gigastack project phase two details

A front-end engineering and design (FEED) study for the deployment of a 100MW electrolyser system at the Phillips 66-operated Humber refinery in North Lincolnshire will be conducted as part of the phase two development of the Gigastack pilot project.

The FEED will incorporate staged installations of electrolyser module systems using ITM Power’s new generation polymer electrolyte membrane (PEM) electrolyser stack technology, with the rated capacity of each electrolyser module system as 20MW.

The power required for the electrolysis process will be sourced from Orsted’s 1.4GW Hornsea Two offshore wind farm which is expected to come online in 2022.

The hydrogen generated at the electrolyser facility will be used for carbon-free refining processes at the Humber refinery.

Demonstration site details

The 100MW electrolyser system will be located at Humber refinery in North Lincolnshire on the northeast coast of the UK.

Spread over a 480acre-site, the refinery is located close to the Hornsea substation.

The crude processing capacity of the Humber refinery is 221,000 barrels per day (bpd).

Objectives of the Gigastack demonstration project

ITM Power will install and test the semi-automated manufacturing machines for producing high-capacity and low-cost electrolyser stacks as part of the project.

Apart from finalising manufacturing designs and the company will also test its new generation of electrolyser stack technology for further cost reduction and improved efficiency.

The Gigastack demonstration project at the Humber refinery will help identify regulatory, technical and commercial challenges involved in the industrial-scale application of renewable hydrogen systems.

ITM Power’s electrolyser manufacturing facility

In July 2019, ITM Power signed a lease agreement to set up a manufacturing facility at PLP Bessemer Park in Sheffield, UK.

The proposed semi-automated manufacturing facility is planned to manufacture 5MW capacity electrolysers. The company currently manufactures electrolysers of only 0.67MW capacity.

Subject to the outcomes of the on-going demonstration project, the annual electrolyser manufacturing capacity of the proposed Sheffield factory will be increased to 300MW by 2023 and 1GW by 2025.

Methods of hydrogen production

Hydrogen can be produced mainly through methods namely electrolysis and natural gas reforming process.

The majority of commercial hydrogen is produced through the natural gas reformation process, which is considered to be a carbon-intensive process.

Whereas, in the electrolysis process, the water is split into hydrogen and oxygen in an electrolyser. The types of electrolysis processes include polymer electrolyte membrane (PEM) electrolysis and alkaline electrolysis.

If the electrolysis process utilises electricity from renewable sources, the net carbon emissions associated with hydrogen fuel production becomes zero.