The Hammerdown gold project is an underground mining project located in the Newfoundland and Labrador province, Canada. Maritime Resources fully owns and will also operate the project.

Pre-feasibility study of the project was completed in March 2017, while the feasibility study is expected to be completed in the last quarter of 2019.

The mine is expected to produce approximately 174,000 ounces (oz) of gold during its estimated mine life of five years.

Hammerdown gold project background

Richmont Mines operated the historical Hammerdown gold deposit from 2000 to 2004 and mined and milled 291,400tof ore. Richmont recovered 143,000oz of gold during the period before ceasing mining activities in 2004 due to lower gold prices.

Hammerdown gold project location, geology and mineralisation

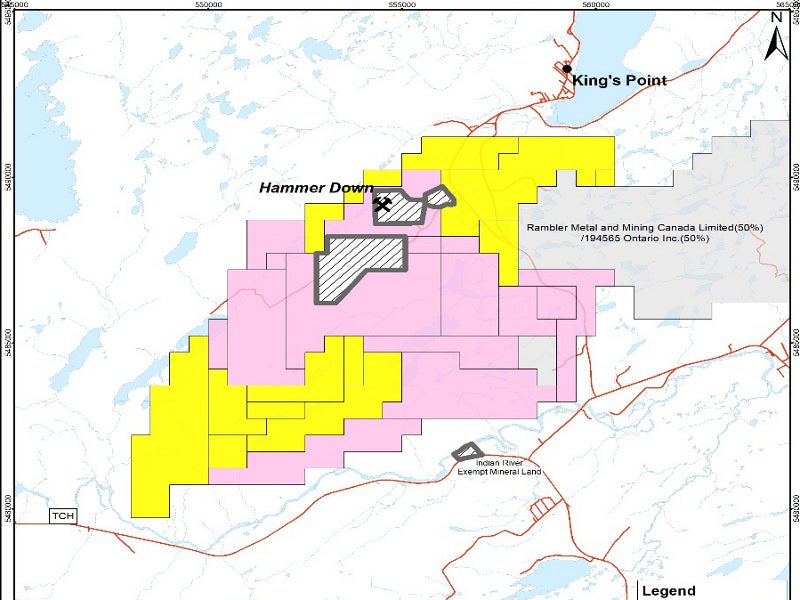

The Hammerdown gold project is located roughly 15km from the Town of Springdale and 5km from King’s Point in Newfoundland, Canada.

The project is part of the Green Bay property, which is placed on the North American Topographic Sheet (NTS). The property also hosts the Orion gold deposit and Lochinvar precious metal deposit.

The Hammerdown project comprises the Hammerdown, Rumbullion, and Muddy Shag veins. It includes the development of an underground mine and associated infrastructure, in addition to surface infrastructure.

The property falls within the north-eastern extremity of the Appalachian Orogen, which comprises volcanic rocks of the Catchers Pond Group and Lushs Bight Group.

The Hammerdown mine is host to nine gold-bearing veins, along with six to eight small or weak vein systems. These veins predominantly comprise vein quartz with 5 to 20 % pyrite that occurs as dense disseminations and massive stringers.

Mineralisation of the Hammerdown vein system is made up of multiple stacked gold vein zones, hosted within a 250m-long section of a 1,800m-long shear zone.

Ore reserves at Hammerdown gold project

The ore reserves of the Hammerdown gold project are estimated to be 700,600t, grading 7.96g/t of gold, while contained gold is estimated to be 179,400oz.

The indicated and measured mineral resources of Hammerdown, Rumbullion, and Muddy Shag veins are estimated to be 925,670t graded at 10.60g/t Au. The contained gold is estimated to be 315,600oz.

Mining at Hammerdown gold project

The Hammerdown underground project will be mined using a combination of longhole and mechanised cut-and-fill mining methods. The original access portal and a small part of the underground workings will be utilised to access the mine, and will be back-filled using hydraulically placed cemented sand fill.

Pre-production and construction works are estimated to take three years, including the installation of underground infrastructure.

Ore processing at Hammerdown gold project

Ore from the Hammerdown deposit will be crushed and transported to the nearby Nugget Pond mill for processing. A new grinding circuit will be constructed to process the material from the Rambler mine.

The Nugget Pond mill is expected to have a nominal production of 400 metric tons per day (mtpd), during the five-year mine plan.

The grinding circuit of the Nugget Pond mill will comprise grinding, leach, and carbon-in-pulp (CIP) circuits to recover gold.

Ore will be crushed to approximately three inches and grinded in an open circuit semi-autogenous grinding (SAG) mill, operating in closed circuit with cyclones. The leach circuit will include four agitated tanks, while the CIP circuit will feature six agitated tanks. The tailings will undergo cyanide destruction and finally sent to the tailings pond.

Infrastructure facilities

The Hammerdown gold project is accessible from Deer Lake on the east, through Highways 390 and 391. It is connected by a 2.6km-long all-weather road to the paved King’s Point highway.

Electricity to the Hammerdown site is proposed to be sourced from the substation located near Springdale, owned by the local electricity provider Newfoundland/Labrador Hydro (NL Hydro).

Bottled water will be the main source of potable water, while a pumping station will be installed near the Beaver Pond to supply fresh water and feed the water storage tank. The pumping station will be housed in an insulated container, through a four-inch diameter buried high-density polyethylene (HDPE) pipeline.

Contractors involved

WSP Canada prepared the pre-feasibility study (PFS) of the Hammerdown gold project, along with a consortium comprising AGP Mining Consultants, SRK Consulting, Gemtec Consulting, and Canenco Canada.

Tetra Tech Consultants prepared and reviewed the mineral resource estimates of the project.

Rambler Metals and Mining (Rambler) prepared the economic feasibility report with regards to the re-opening of the previously producing Hammerdown gold project, under an engineering, evaluation, and services agreement.