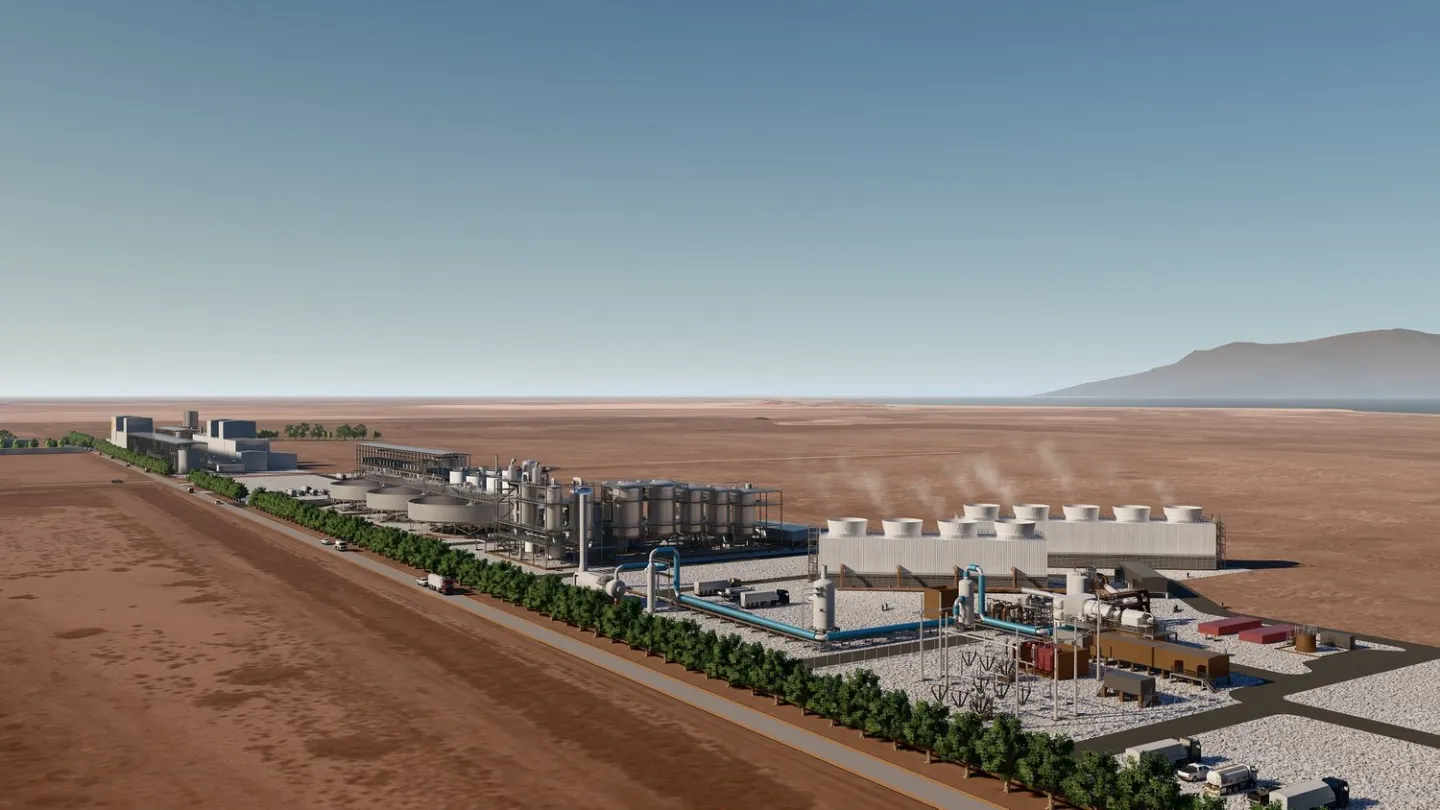

Hell’s Kitchen is a geothermal lithium project being developed in Imperial County, California, the US. It is the first geothermal project to be developed at the Salton Sea in ten years.

The integrated project will involve recovering lithium from geothermal brines and producing geothermal power and battery-grade lithium products.

Controlled Thermal Resources Holdings (CTR), a US-based company offering renewable energy and lithium extraction services, owns the project.

CTR commenced construction and drilling activity in April 2021. The company broke ground on Hell’s Kitchen lithium and renewable power production facility in January 2024.

Hell’s Kitchen Project Specifications

The project area will be within Sections 10, 11, and 12, Township 11 North, and Range 13 East in Imperial County. It lies near the eastern shore of the Salton Area.

The project entails a total estimated investment of around $1.8bn.

Hell’s Kitchen Integrated Lithium and Power Project will be delivered in multiple stages.

It is expected to produce 49.9MW of renewable power and around 25,000 metric tonnes of lithium hydroxide from its first stage.

Overall, Hell’s Kitchen project has a projected resource capacity to produce 1,100MW of baseload renewable power and around 300,000 metric tonnes of lithium carbonate equivalent (LCE) products annually.

Hell’s Kitchen Project Development

Overall, the project will involve two schemes.

The power scheme will generate around 49.9MW of net geothermal power, which will be delivered to Imperial Irrigation District (IID) system through a 2-mile-long 230kV line to an existing interconnect station at Hudson Ranch.

Key components will include a geothermal plant; production and injection wells and well pads; geothermal fluid production and injection pipelines; a brine pond and processing facility; a geothermal turbine generator facility; and a heat rejection system.

Other infrastructure will include storage and control buildings; warehouse; water storage pond and tanks and a substation.

The other scheme will include mineral extraction and processing facilities to produce lithium hydroxide, silica, bulk sulphide, and polymetallic products.

It will also include supply and receiving pipelines to transport geothermal brine from the power scheme.

An interconnecting power line will supply power to the facilities.

The project will use renewable energy and steam to recover lithium from geothermal brines to produce battery-grade lithium products.

The process will seek to eliminate the need for evaporation brine ponds, open pit mines and fossil-fuelled lithium processing.

CTR completed drilling two full-diameter commercial wells, HK1 and HK2, to measured depths of 8,000ft and 8,618ft, respectively. The Direct Lithium Extraction (DLE) unit achieved a 95-97% lithium recovery rate.

CTR and its technology partners have also completed a $60m brine optimisation programme.

Offtake Agreements

In July 2021, General Motors formed a strategic investment and commercial collaboration with CTR to secure local and low-cost lithium. A significant amount of battery-grade lithium hydroxide and carbonate will be sourced from the Hell’s Kitchen project.

CTR has also signed a letter of intent (LoI) with US-based Statevolt to supply lithium and power for the latter’s proposed 54GWh battery manufacturing plant in Imperial County.

Stellantis, a multinational automotive manufacturing corporation, announced an investment of more than $100m to advance the development of the Hell’s Kitchen project in August 2023.

Stellantis and CTR also expanded the initial agreement signed in June 2022 to supply 65,000 metric tonnes of battery-grade lithium hydroxide monohydrate (LHM) each year over a ten-year period.

CTR will commence battery-grade lithium hydroxide monohydrate supply for Stellantis in 2027.

Contractors Involved

Hatch, a global multidisciplinary management, engineering and development consultancy, has been appointed by CTR as the project’s engineering and project management partner. It has completed the project’s NI 43-101 Preliminary Economic Assessment.

CTR engaged Lilac Solutions to develop a lithium extraction pilot facility by leveraging proprietary ion exchange technology.

In October 2022, CTR appointed Hargrove Engineers & Constructors as the engineering contractor for the scheme to recover lithium from sub-surface geothermal brine.

In March 2023, CTR and Fuji Electric Corp. of America (FEA) signed a Memorandum of Understanding (MoU) for multiple Equipment, Procurement, and Construction (EPC) contracts to deliver geothermal power facilities at the project.

The EPC contracts, with a combined value of $1.4bn, include completing a Stage 1 power facility and delivering five additional facility configurations.

In June 2023, CTR selected Aquatech as its technology partner to deliver the purification process plants for the company’s Stage 1 Lithium Hydroxide Facility.