Ikkari is a planned gold deposit development located within Rupert Lapland Project area in northern Finland. The Rupert Lapland area is 100% owned by gold exploration and development company Rupert Resources.

The company filed the preliminary economic assessment (PEA) report for the discovery in January 2023. This was followed by the completion of a Pre-feasibility Study (PFS) for the project in February 2025.

The PFS projected a 20-year life of mine (LOM) consisting of an open-pit operation for the first ten years, and underground mining for the remaining period.

Initial capital requirement is estimated to be $575m, including contingencies.

With a long-term market consensus gold price of $2,150 per troy ounce (oz), the Ikkari project is projected to yield favourable post-tax financial outcomes, including a post-tax Net Present Value (5% discount) (NPV) of $1.7 billion, an Internal Rate of Return (IRR) of 38%, and a payback period of 2.2 years.

The project is expected to achieve first gold pour in 2030.

Ikkari Project Location

The Ikkari Gold Deposit is located within the Rupert Lapland Project’s exploration licences, surrounding the village of Rajala in the municipality of Sodankylä. It lies about 30km northwest of Sodankylä town centre and approximately 22km west-southwest of the Pahtavaara Mine, which is currently under care and maintenance.

The terrain in the Ikkari deposit area is mostly flat, with an elevation of around 225m above sea level (m asl), gradually rising towards the southeast near the edges of Iso-Pulkittama hill.

The Rupert Lapland Project covers a contiguous area of 340.6km², comprising mining licences, exploration permits, and permit applications. The Ikkari deposit specifically falls within the Heinälamminvuoma exploration permit (ML2011:0033), which spans 84km².

Geology and Mineralisation

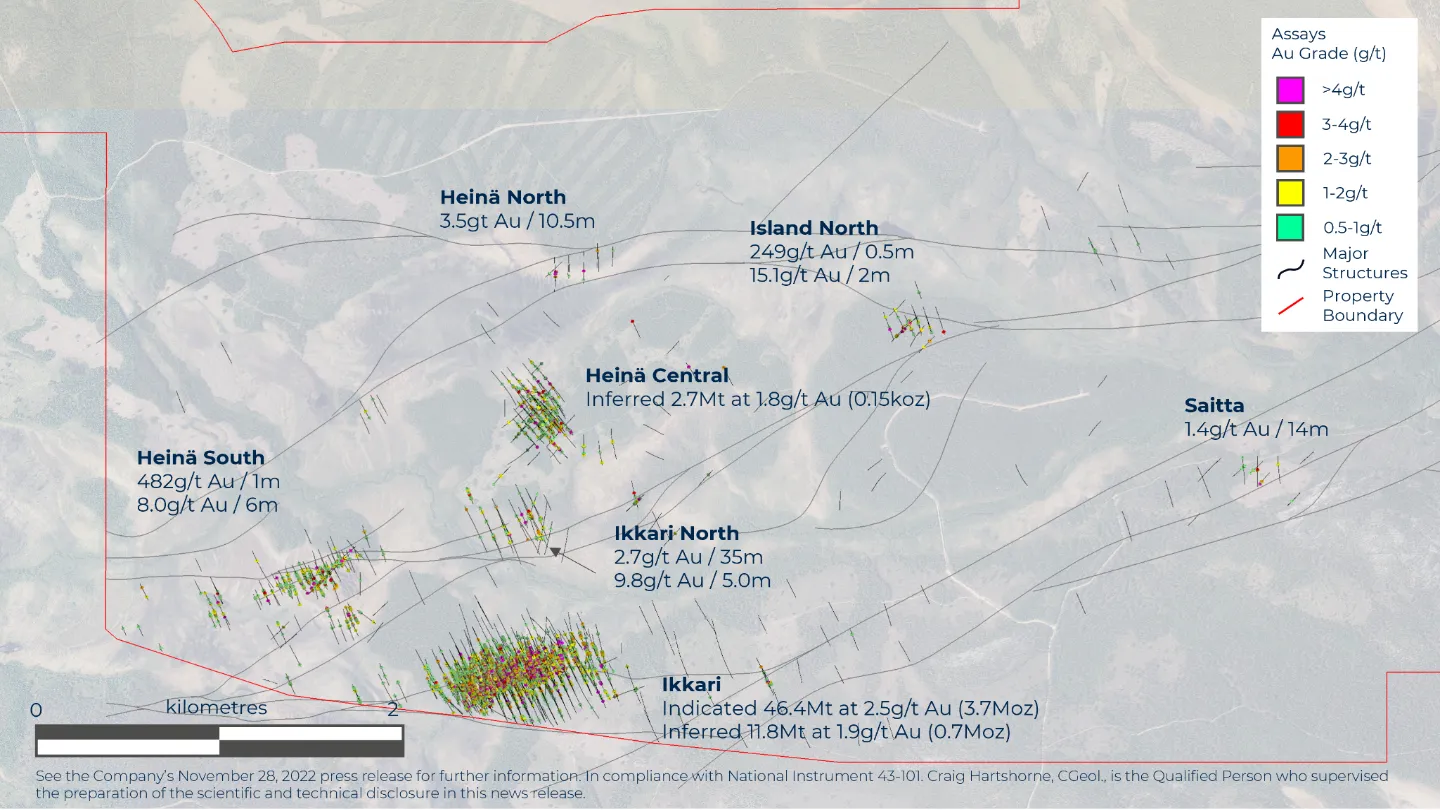

Discovered in 2020, the Ikkari deposit is positioned at the easternmost section of the Sirkka Line, a tectonic feature extending across northern Finland that hosts approximately 25 to 30 gold deposits or occurrences.

The deposit lies beneath a layer of glacial till ranging from 10m to 40m in thickness and occupies a structurally complex zone. This area is situated between thrust-imbricated metavolcanic and metasedimentary rocks of the Savukoski Group and synorogenic, molasse-type siliciclastic formations of the Kumpu Group.

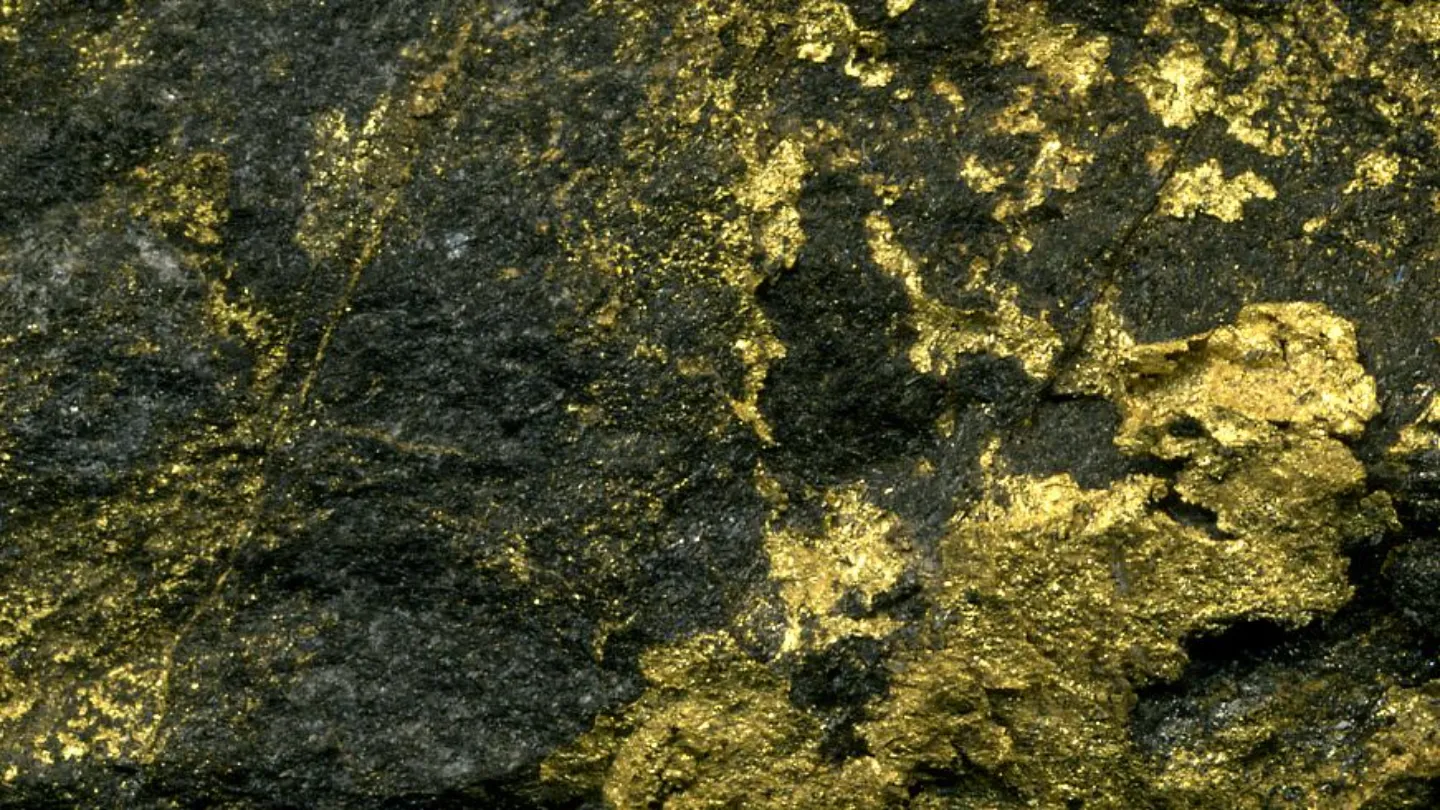

Regionally, the Ikkari deposit is hosted within greenschist-metamorphosed mafic-ultramafic volcanic rocks of the Savukoski Group. Gold mineralisation is primarily localised along the structurally modified unconformity between the Savukoski and Kumpu Group strata.

Ikkari is classified as an orogenic, hydrothermal gold deposit hosted by disseminated and vein-hosted pyrite. Free gold, commonly occurring as around 1mm grains, is also present. Gold mineralisation is typically found on pyrite grain surfaces or within fractures in the pyrite.

Ikkari Project Mineral Reserves

Rupert Resources updated Mineral Resource Estimate (MRE) for its Ikkari Project in November 2023.

The updated MRE contains Indicated Resource of 58.43 million tonnes (Mt) at a grade of 2.18 grams per tonne of gold (g/t Au) for 4.09 million ounces (Moz) contained gold.

It also reported an inferred resource of 3.58Mt at a grade of 1.18 g/t Au for 136,000 ounces of contained gold.

The gold mine contains a probable mineral reserve of 52Mt at 2.1g/t Au for 3.5Moz Au. This represents an 85% Mineral Resource to Mineral Reserve conversion.

Mining and Processing

The Ikkari deposit will be mined using both open pit and underground methods.

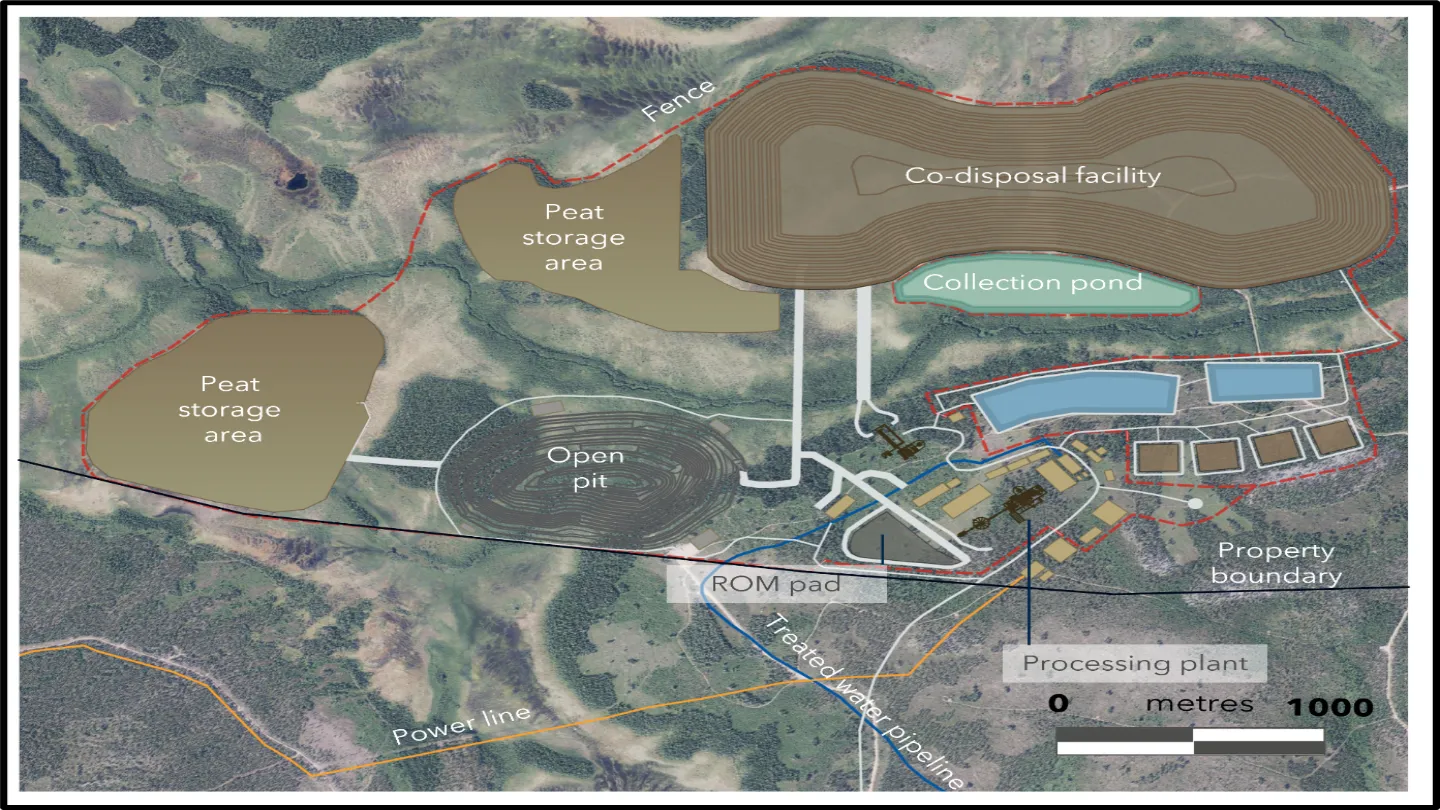

Open pit mining will utilise a truck and shovel setup, with drilling and blasting carried out on 10m benches. It will extend from the surface (230 mL) down to -80 mL and will be developed in two phases. The total open pit inventory is estimated at 36 million tonnes (Mt) at an average grade of 2.2 grams per tonne (g/t), containing 2.5 million ounces (Moz) of gold.

Open pit mining is set to begin in Year 1, with a year of pre-stripping before the first gold pour. Ore production from the open pit is expected to reach 3.5Mt per year and will continue until Year 11.

For underground mining, Long Hole Open Stoping (LHOS) has been selected, incorporating a combination of paste and waste rock backfill. Access will be provided via two declines—one extending from the surface to the east of the open pit and another from the 40 mL switchback within the pit, which will be used once open pit operations conclude.

The underground mine will be ventilated through four shafts, comprising two exhaust shafts and two for fresh air supply, with heating available when necessary. Ore will be hauled to the surface using trucks through the two declines.

Construction of the primary decline is scheduled to start in Year 6, with underground stoping operations commencing at the end of Year 10. Underground mining is expected to continue until Year 20, with a total underground inventory of 16 Mt at 1.93 g/t, containing 1.0 Moz of gold. Annual underground ore production is planned at 2.0Mt.

Over the expected 20-year mine life, a total of 52 Mt of ore will be processed, with an average grade of 2.1g/t, yielding approximately 3.5 Moz of contained gold.

The processing plant flowsheet begins with primary crushing using a jaw crusher, followed by a covered crushed ore stockpile and a reclaim tunnel. The grinding circuit follows a standard SABC (Semi-Autogenous Grinding, Ball Mill, and Pebble Crusher) configuration, where a SAG mill operates in closed circuit with a pebble crusher, followed by a ball mill and classifying cyclones.

Gold recovery is enhanced by a gravity recovery and intensive leach circuit, which extracts liberated gold from the cyclone underflow. The cyclone overflow is thickened before entering the carbon-in-leach (CIL) circuit. Gold is then extracted through a pressure Zadra elution system, recovered via electrowinning, and cast into doré bars.

Tailings from the CIL circuit undergo detoxification in an SO₂/Air cyanide destruction circuit before being pumped to the filtration plant located nearby. A future paste plant is planned adjacent to the filtration plant.

The processing plant’s tailings are thickened in a high-rate thickener before being fed into three horizontal pressure filters. The filtered tailings are stored in a building next to the filtration plant, where they are reclaimed for co-disposal.

Based on metallurgical testwork and the designed flowsheet, the overall gold recovery rate is projected to reach 95.8%.

Contractors Involved

Consulting firm WSP Finland Oy conducted the Preliminary Feasibility Study (PFS) and prepared the technical report.

Several other consulting organisations were also involved for information and data points. This includes Mine Environment Management, Envineer, Piteau Associates Engineering, Grinding Solutions, Stress Measurement Company, Geolabs, Terratec Geophysical Services, SRK Finland, Afry Finland, Tektonik Consulting, and Know Flow.