Johan Sverdrup offshore oil field is located approximately 150km away from the coast of Stavanger, Norway in the Norwegian North Sea. It is considered to be one of the biggest oil fields in the Norwegian continental shelf.

The field is jointly owned by Equinor (40.02%, operator), Lundin Norway (22.6%), Petoro (17.36%), Aker (11.5%) and Total (8.4%). It is being developed in two phases, with an estimated investment of approximately Nkr86bn ($10.3bn) on the first phase and Nkr41bn ($4.9bn) on the second.

Construction on phase one of the offshore project began in March 2016, while production is expected to be started by the end of 2019.

The plan for operation and development (PDO) of phase two was submitted to the Norwegian Ministry of Petroleum and Energy in August 2018 and the same was approved in May 2019.

Construction on the second phase was started in the same month, with commissioning scheduled for the fourth quarter of 2022.

The production life of Johan Sverdrup field is approximately 50 years, while its peak production capacity is estimated to be 660,000 barrels of oil per day (bpd).

Johan Sverdrup offshore field discovery, geology, and reserves

The Johan Sverdrup oil and gas field is located in the Utsira High, which lies south-west of the Norwegian continental shelf.

It consists of two oil discoveries named Avaldsnes and Aldous, which were discovered in 2010 and 2011 respectively and located at a water depth of 110m-120m.

The field is estimated to contain recoverable reserves between 2.2 and 3.2 billion barrels of oil-equivalent.

Johan Sverdrup phase one development details

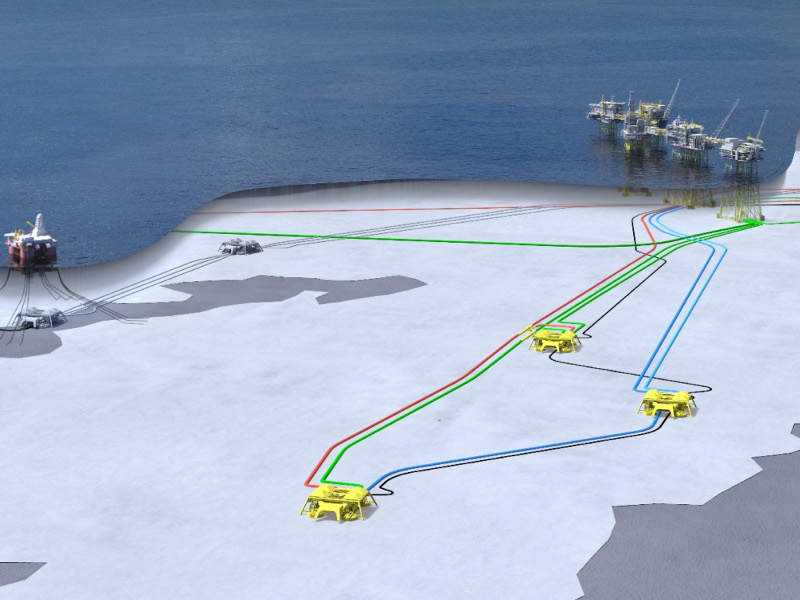

Phase one of the Johan Sverdrup field development includes the construction of four platforms, three subsea installations for water injection, and oil export pipelines with a total length of 400km. It is expected to produce 440,000 barrels of oil a day.

The oil from the production platform will be transported to the Mongstad terminal located in Hordaland through the Mongstad pipeline, while the gas will be transported by the Karsto pipeline to the Karsto gas processing plant located in North Rogaland.

The construction work for the phase one began in March 2016. The installation works for all subsea systems along with the installation of the riser platform (RP) and the drilling platform (DP) were completed in 2018. The topsides for the processing platform and utility-living quarters are to be installed in 2019, while the laying of Mongtad and Karsto oil export pipelines was completed in September 2018.

The processing topside for Johan Sverdrup phase one weighs approximately 28,100t and measures 139m-long, 69m-wide, and 72m-tall. Manufactured at the Samsung Heavy Industries yard in South Korea, it was transported to Norway on the semi-submersible heavy transport vessel Boskalis Vanguard.

Johan Sverdrup phase two development details

The second phase of Johan Sverdrup offshore oil and gas field includes the drilling of 28 wells and construction of one processing platform and five new subsea templates. Modifications to the riser platform and the field center will also be carried out.

The oil processing platform will weigh 23,000t and consist of three modules including the upper process module, a converter module, and the main support frame. Construction on the processing platform began in Aibel’s construction yard in Haugesund, Norway, in May 2019.

The average production of phase two is estimated to be approximately 220,000bpd, which will bring the total production capacity of the field to 660,000bpd.

Electricity supply for Johan Sverdrup

The Johan Sverdrup offshore field will be powered from two onshore converter substations at Haugneset, east of Karsto, which will be connected to the converter module of the processing platforms of the field.

The power cable system will consist of two high-voltage power cables with a length of 200km each. The power cables will link the high-voltage direct current (HVDC) equipment of the processing platforms to the HVDC equipment of the onshore converter substations.

Contractors involved in Johan Sverdrup phase two

Subsea 7 was contracted for subsea pipelines and associated marine operations of Johan Sverdrup phase two in June 2019. The contractual scope includes the supply and installation of 100km of infield pipelines, 25 spools, and umbilicals.

TechnipFMC was contracted for the subsea production system if Johan Sverdrup phase two that includes five templates and 18 X-mas trees, in March 2019.

Aker Solutions provided front-end engineering and design (FEED) services for the phase two processing platform, while Kvaener provided FEED for the jacket.Equinor signed a letter of intent with Aibel in April 2018 to provide engineering, procurement, and construction (EPC) services for the topsides of the phase two processing platform, under a Nkr8bn ($900m) contract.

Equinor also signed a letter of intent with a joint venture between Aker Solutions and Kvaerner for an EPC contract worth Nkr3.4bn ($410m) for the utility module of the phase two platform. The scope of the contract also includes modifications required to the riser platform of the field.

Aker-Kvaener JV subcontracted PG Flow Solutions for delivering a mono ethylene glycol and chemical injection pump for the utility module.

NKT, a company based in Denmark, signed a letter of intent with Equinor in October 2018 for a contract worth Nkr1bn ($120m) for the engineering, procurement, fabrication, installation, and testing of the cable system for the phase two development.

Siemens is responsible for supplying electrical equipment, while Kongsberg Maritime was contracted for providing safety and automation systems.

Contractors involved in Johan Sverdrup phase one

Aker Solutions provided feasibility and concept studies, as well as executed the FEED for Johan Sverdrup phase one in 2014.

It was awarded the engineering services, procurement and management assistance (EPMA) contract for the first phase development of the field in late-2013.

Aker Solutions was also responsible for engineering and procurement of the process and riser platforms.

Kvaerner delivered three steel jackets and built the utility and living quarter platform, while Samsung Heavy Industries built the processing platform for Johan Sverdrup phase one.

Aibel supplied the drilling platform for phase one and was contracted for building two onshore converter stations for the Johan Sverdrup field development.

Subsea 7 and TechnipFMC were engaged as major subsea contractors, while NKT undertook the supply and installation of the power cables for phase one.

Kaefer Energy was awarded the insulation, scaffolding, and surface treatment (ISO) services for the Johan Sverdrup field in May 2019.

Other major contractors involved in phase one development include Siemens, Kongsberg Maritime, ABB, IKM Ocean Design, and Odfjell Drilling.