Kangankunde Rare Earths Project is a large, rare earth deposit located in Malawi, a landlocked country in Southeastern Africa.

The project is owned by the Australian company Lindian Resources. The company announced the completion of a positive feasibility study (FS) on Stage I of Kangankunde Rare Earths project in July 2024.

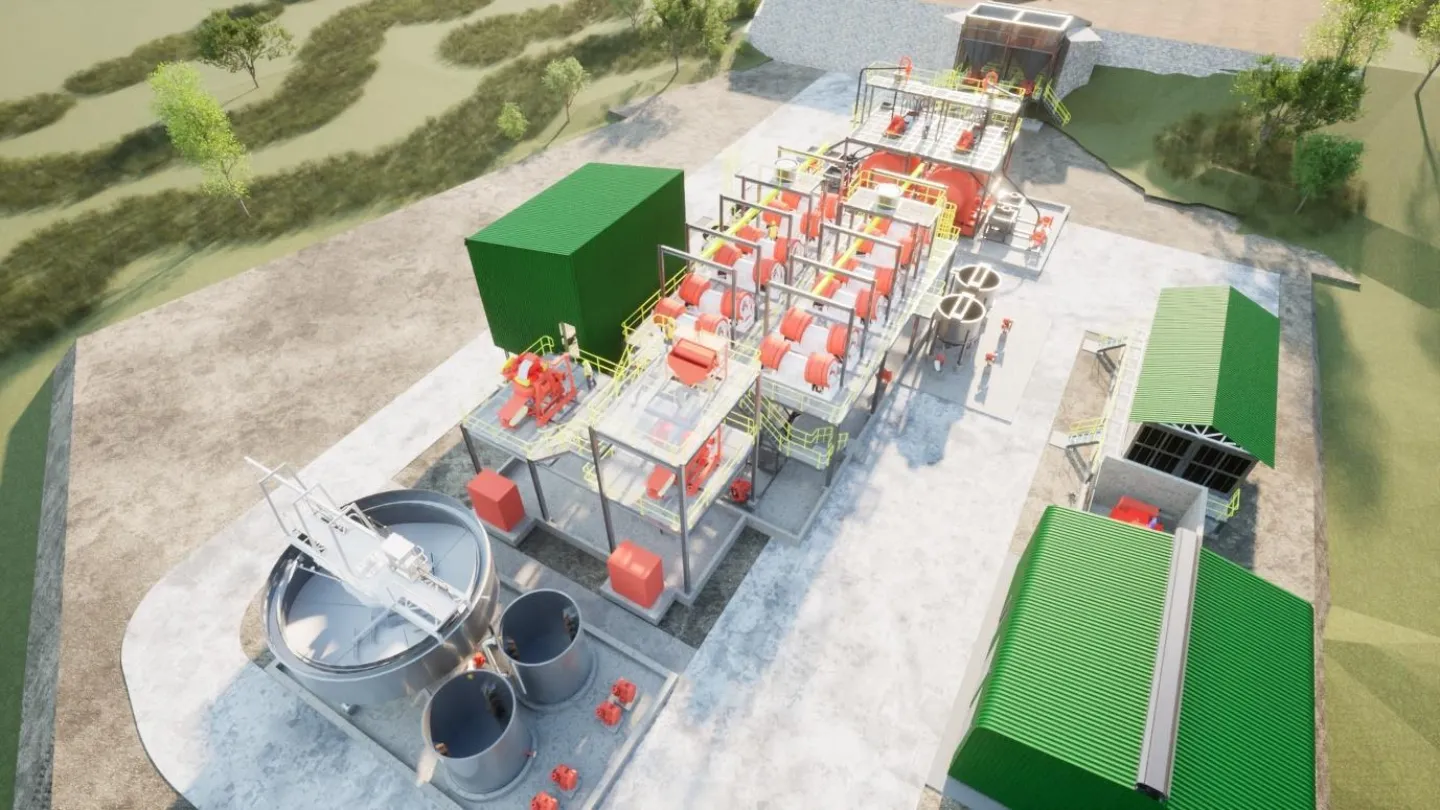

The first stage will include mining operations, a mineral processing plant, and necessary ancillary infrastructure. It will focus on producing monazite concentrate.

The results of the FS confirmed a technically low risk Stage I development with a potential expansion in the future.

According to the FS, Kangankunde project will entail a pre-production capital cost of $40m including a 12.5% contingency.

Stage I is expected to produce 15,300 tonnes per annum (tpa) of premium concentrate with 55% Total Rare Earth Oxides (TREO) grade for a life-of-mine (LOM) of 45 years.

Construction works at the site is expected to begin in the fourth quarter of 2024, following funding confirmation.

The processing plant is slated to be commissioned in the fourth quarter of 2025, with first production targeted for Q1 2026.

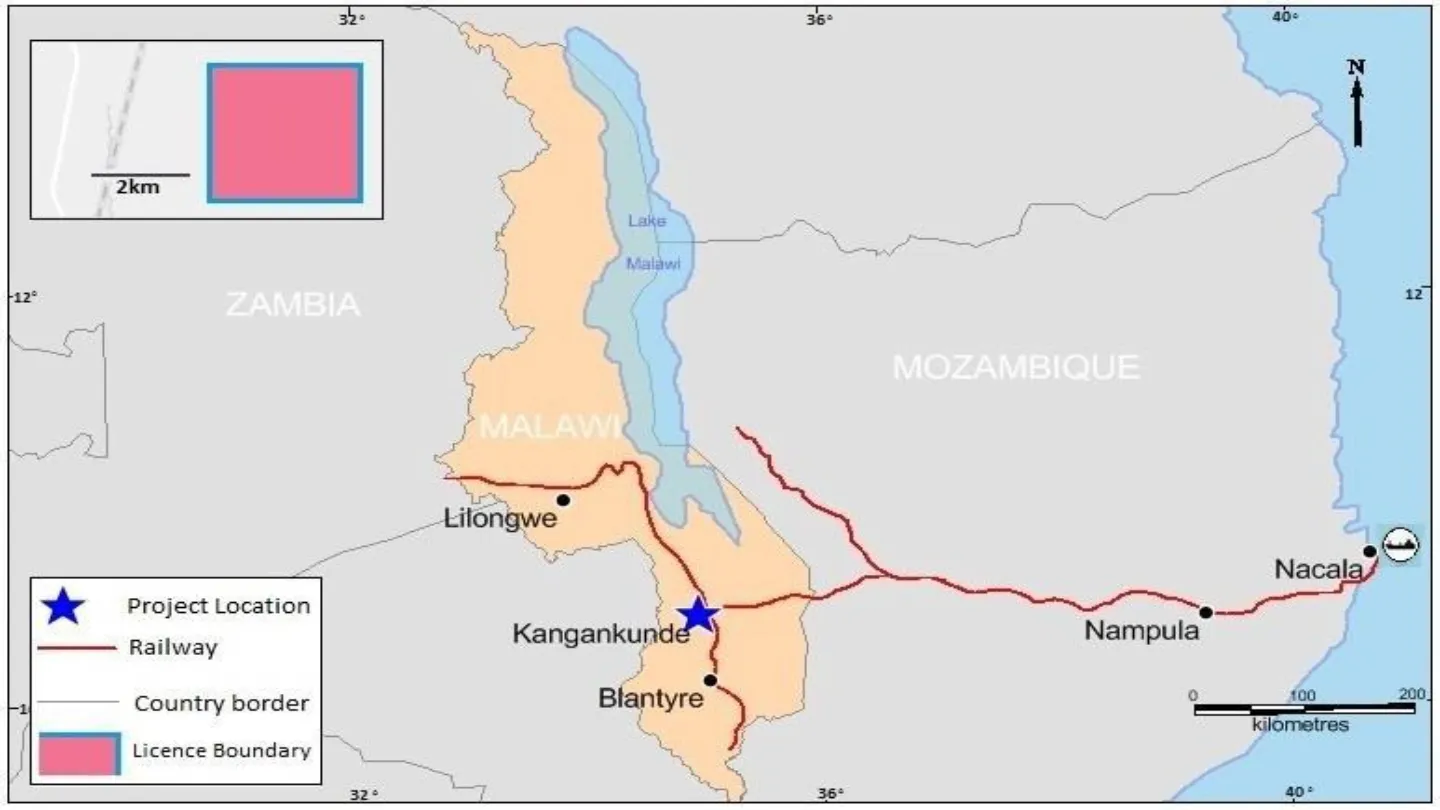

Kangankunde Project Location and Site Access

The Kangankunde Project is located around 90km north of the city of Blantyre and 13km south of Balaka in Malawi.

Mining lease area includes an area of around 900 hectares. The Stage I development plan includes an area of 364 hectares.

The project can be accessed by a sealed road from Blantyre and Balaka via the M1 highway. An unsealed 5km road leads to the site.

It is also known for its proximity to the Nacala corridor railway line, which is situated 9km to the east, providing the project with access to the deep-water Port of Nacala.

Ownership and Licencing Timeline

At Kangankunde, significant exploration and test work was carried out between the 1960’s and 1990’s, leading to the identification of higher-grade mineralisation.

In August 2018, Lindian Resources signed an exclusive option agreement with Rift Valley Resource Developments Limited (RVR) to acquire up to a 75% interest in the Kangankunde Rare Earths Project.

The company reached an out-of-court settlement regarding the acquisition in May 2022.

In August 2022, Lindian entered into an agreement to acquire 100% shares of RVR to become the sole owner of the Kangankunde Rare Earths Project.

As agreed, Lindian will pay $30m consideration in tranches over 48 months.

The company is expected to make the final tranche payment at or before the commissioning of the process plant.

Kangankunde Rare Earths Project has received all key permits.

The project received environmental licence in Q3 2021, followed by mining licence in Q2 2022.

Water permit was issued in April 2024.

Lindian also announced maiden mineral resources for the project in the third quarter of 2023 and maiden ore reserves in the second quarter of 2024.

Geology and Mineralisation

The Chilwa Alkaline Province of Southern Malawi hosts the Kangankunde carbonatite complex. The complex exhibits a structure of a low hill with a height of nearly 200m more than the surrounding plain.

It features a central carbonate core encompassed by a range of carbonatite-rich rock composed primarily of dolomite, siderite and ankerite. The zone gradually transitions to fenitised polymictic breccias and gneiss at the periphery.

Rare earth mineralisation primarily contains monazite ((RE)PO4).

Although carbonatite-rich rocks and breccias host primary mineralisation, other rock types also contain some minerals.

Kangankunde Project Reserves

Kangankunde Project’s Mineral Resource Estimate (MRE) includes 61 million tonnes (mt) of indicated resource grading 2.43% TREO (0.5% TREO cutoff grade) containing 0.3 million tonnes of neodymium-praseodymium (NdPr).

MRE in the inferred category includes 200mt grading 2.05% TREO.

The project is estimated to contain a probable reserve of 23.7mt grading 2.9% total rare earth oxide (TERO) with a NdPr content of 19.7%. Contained NdPr is estimated at 679,000t.

Mining and Ore Processing

Kangankunde Project Stage I will seek to achieve a throughput rate of 60 tonnes per hour to deliver an annual throughput of around 450,000 tonnes.

This will lead to the production of a nominal 15,000 tonnes of rare earth monazite concentrate per annum with a 60% recovery rate and an average TREO grade of 55%.

Kangankunde Project’s high-grade, near-surface mineralisation will enable open pit mining operation using conventional drill, blast, load and haul methodology.

The mine is designed in six stages based on on-specification grade ore.

A hydraulic excavator will load the blasted material into dump trucks, which will haul it from each mining stage to the ROM pad or other material stockpile. The ROM ore will undergo ore crushing in primary jaw crusher and secondary cone crusher.

The crushed ore will be fed into the processing plant. It would reach the ball mill via vibrating plate feeders in order to liberate monazite.

The milled material moves through a trommel and into a sump, while oversized scats are removed.

A scalping screen filters the slurry to enable preliminary classification. It will be then pumped to a deslime cyclone cluster to remove ultrafine particles.

Multi-Gravity Separators (MGS) will be used for initial rougher gravity separation to achieve a concentrate grade of approximately 30% TREO. Additional cleaner gravity recovery improves the concentrate to 35-45% TREO.

Further, the concentrate will undergo magnetic separation via Low-Intensity Magnetic Separators (LIMS) and Wet High-Intensity Magnetic Separators (WHIMS).

Magnetic fractions will be collected and conditioned, and rougher/scavenger and cleaner flotation will be used to remove impurities.

Non-magnetic fractions and sulphide tailings will be discarded, while the final monazite concentrate will be collected.

The concentrate will be then dewatered, dried and bagged for storage and transported to Nacala Port.

Key Support Infrastructure

Processing operations of the rare earth project would require 3MW of power. It would be sourced from the national grid. It will also have a diesel generator as backup.

A 24-km power line corridor from the existing substation may be laid for power supply.

The project will receive water supplies from dedicated boreholes and then store it in two reservoirs.

The first 500 cubic metre capacity reservoir will serve the processing plant and mining operations, while the second 100 cubic metre capacity reservoir will supply treated water for domestic use.

Kangankunde Project will also have tailings storage facility, an explosives storage facility, administration area building and accommodation facilities among others.

Contracts and Offtake Agreements

The FS was carried out under the management of Lindian’s internal team. Experts from several entities were associated with the execution of the study.

This includes, among others, Cube Consulting for mineral resource estimation and pit shell optimisation, Geotheta for tailings storage facility, Orecraft for process plant and infrastructure cost estimate and Mine Planning Services for mine planning, design and scheduling works.

In September 2023, Lindian signed a contract with global metals trading company Gerald Metals for the supply of 45,000 tonnes of rare earths concentrate from the Stage 1 development of the Kangankunde Rare Earths Project.