The Kasawari gas field is an offshore gas field being developed in the Malaysian part of the South China Sea. Petronas Carigali, a wholly-owned subsidiary of the Malaysian national oil company Petronas, is the developer and operator of the Kasawari gas field.

Discovered in November 2011, the Kasawari field is estimated to contain approximately three trillion cubic feet (tcf) of recoverable gas resources.

Scheduled to come on-stream in 2023, the offshore gas field is expected to produce up to 900 million cubic feet of gas (mcf) a day.

The gas output of the field will be supplied to the Petronas LNG Complex in Bintulu, Malaysia.

Location and site details

The Kasawari gas field is located in the South China Sea off the coast of Sarawak in Malaysia. The field lies in approximately 108m-deep waters within block SK316, approximately 200km north of Bintulu in the Sarawak state of Malaysia.

Gas field development details

The Kasawari field development plan includes a central processing platform weighing approximately 47,000t, a wellhead platform weighing approximately 8,600t, and a flare structure.

The central processing platform will be connected to a wellhead platform and flare structure by two separate bridges. Capable of processing up to 900 million cubic feet of gas a day (mcf/d), the Kasawari central processing platform is expected to be the heaviest and biggest offshore platform in Malaysia.

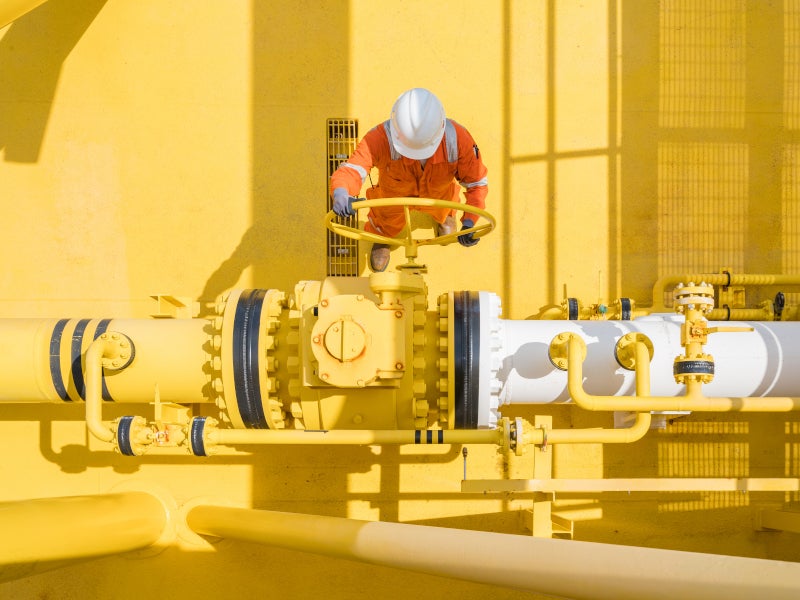

Kasawari is a sour gas field containing relatively higher levels of carbon dioxide. The centrifugal compressors will be used to compress the gas processed in the central processing facility. The compressed gas will flow through an 80km-long pipeline from the central processing platform to a riser platform. The gas will be further processed and liquefied at Petronas LNG Complex in Bintulu.

The Petronas LNG complex consists of nine production trains with a total capacity of 29.3 million tonnes per annum (Mtpa). It is one of the biggest LNG production facilities in the world.

Contracts awarded

Honeywell UOP entered into an agreement with Petronas Carigali to provide modular natural gas processing technology for the offshore gas processing plant of the Kasawari gas field in July 2020. UOP’s acid gas removal technologies including MemGuard and Separex are used to remove contaminants such as carbon dioxide, hydrogen sulphide and mercury from natural gas. UOP’s Separex membrane manufacturing unit in Penang, Malaysia, will supply elements for the membrane system.

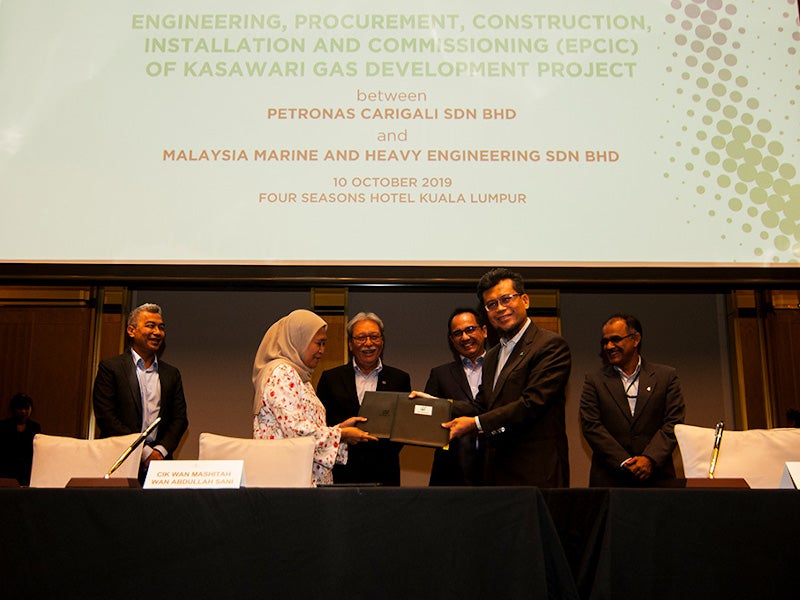

Malaysia Marine and Heavy Engineering (MMHE) was awarded an engineering, procurement, construction, installation, and commissioning (EPCIC) contract for the Kasawari gas development project in July 2019.

The contract scope included the construction of a central processing platform, a wellhead platform, and a flare structure as well as the laying of an 85km-long pipeline from the central processing platform to the existing E11R-A platform. The contract will be executed by a joint-venture between MMHE and TechnipFMC.

Siemens Gas and Power received a contract to supply three SGT-300 industrial gas turbine generators (GTG), three SGT-300 mechanical drive gas turbines, and three DATUM centrifugal compressors for the project from the MMHE and Technip FMC joint-venture in June 2020.

Each SGT-300 GTG unit, with dual-fuel capability, will have a capacity of 7.9MWe. The three SGT-300 GTG units will supply power to the central processing platform and the wellhead platform. While three SGT-300 mechanical drive gas turbines will power the DATUM centrifugal compressors.