Knarr offshore oil and gas field in the Norwegian North Sea operated from March 2015 to May 2022. The field was discovered in 2008, and the Norwegian government approved the Plan for Development and Operation (PDO) in 2011.

It had an initial recoverable reserves of 11.2 standard cubic metres of oil equivalent (Sm3oe).

Norske Shell, a Norwegian subsidiary of Shell, is the operator of the field with 45% interest. Wintershall Dea Norge (30%), and INPEX Idemitsu Norge, a subsidiary of Japan’s energy company INPEX, (25%) are the other two licence partners.

Following the shut down in 2022, the Knarr Floating Production Storage and Offloading (FPSO) was removed from the field.

In May 2024, the Norwegian Ocean Industry Authority (Havtil) gave its consent to Norske Shell for decommissioning and removal activities at the Knarr field. Decommissioning of the field subsea infrastructure will be completed by 2028.

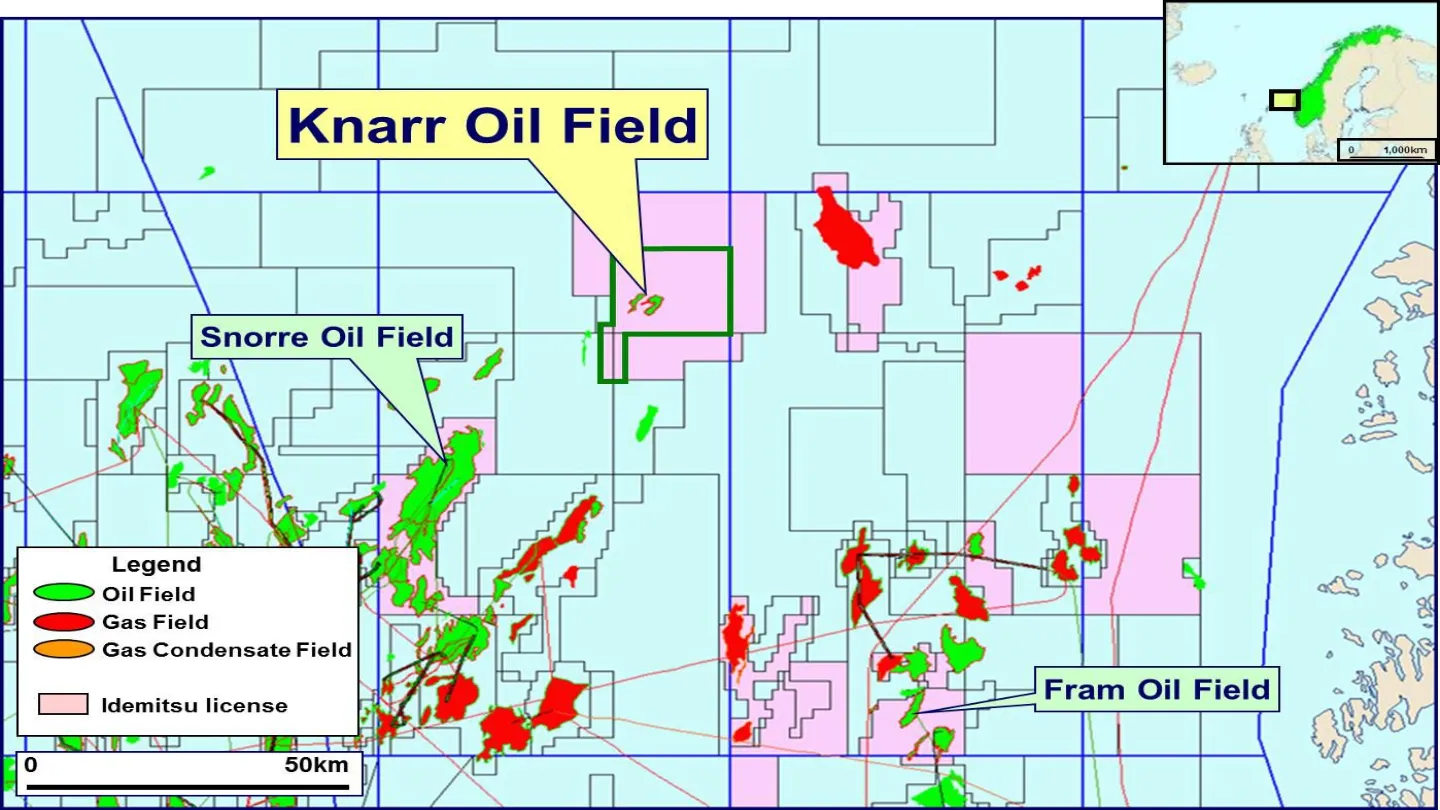

Knarr Field Location

Knarr field (formerly called Jordbær) is located in the Norwegian North Sea, around 50km northeast of the Snorre Field in a water depth of around 400m. The site is around 122km west of Norwegian town Florø.

It lies within production licence 373S of block 34/3 within the Tampen area.

Discovery and Appraisal

Knarr field was discovered in 2008 by the 31/3-1S well. The well was drilled by semi-submersible Bredford Dolphin drilling rig, proving an oil accumulation in a reservoir of Jurassic age.

It was drilled to a total depth of vertical depth of 4,057m below sea level and completed in the Triassic.

An appraisal well, 34/3-1A, was then drilled in the same year to delineate the discovery. It was drilled to a vertical depth of 3,974m below the sea level concluding in Lower Jurassic rocks.

In 2011, wildcat well 34/3-3 S and appraisal well 34/3-3 A were drilled west of the Knarr field. Both the wells proved oil in Early Jurassic sandstones.

Well 34/3-3 S proved oil in the upper part of the Cook formation with very good reservoir quality, while the 34/3-3A sidetrack identified the extent of reservoir rocks and proved oil in the lower part of the Cook formation.

These two wells were drilled the West Alpha drilling facility.

The Knarr field reservoirs are located at a depth of 3,800m, with oil produced from Lower Jurassic sandstone in the Cook Formation.

The offshore field was estimated to contain gross recoverable reserves of around 80 million barrels of oil equivalent.

Knarr Field Development

Knarr field development included two segments- Knarr West and Knarr Central. It involved the installation of the FPSO Petrojarl Knarr near the field.

The FPSO was connected to six production and injection wells via two subsea templates.

The produced hydrocarbons were transported via wells to the FPSO for processing, storage, and offloading.

The injection wells were used to push water into the reservoir for pressure maintenance.

After processing, oil was offloaded to shuttle tankers for export. Gas from the FPSO was transported via the Far North Liquids and Associated Gas System (FLAGS) to St Fergus in the UK.

Petrojarl Knarr FPSO Details

The mooring-type Petrojarl Knarr FPSO was built in 2014 at Samsung heavy Industries’ shipyard. The vessel is 256m long and 48m wide.

It was owned by offshore sustainable solutions provider Altera Infrastructure.

The FPSO has an oil production capacity of 63,000 barrels of oil per day (bopd) and can handle 47 million standard cubic feet of gas per day.

Petrojarl has 15 riser slots, a storage capacity of 800,000 barrels (bbls) of oil, and can accommodate 100 people.

Key Knarr Field Contractors

Subsea 7, a subsea solutions provider, was selected to supply a flowline bundle solution for the offshore oil and gas project. Butting supplied Subsea 7 with pipes which will be used in bundle technology.

Teekay won the $1bn engineering, procurement and construction contract for Petrojarl Knarr.

Aibel, energy infrastructure builder, prepared the FPSO for installation at its yard in Haugesund. Vassnes Solutions supported Aibel with the work.

Fairmount Marine, a subsidiary of Boskalis, was awarded a tow-out and towage contract of Petrojarl from Geoje, South Korea, to the Haugesund Port, Norway.

Corinth Pipeworks, a steel pipe manufacturer, supplied offshore gas export pipes.

TechnipFMC carried out a flow calibration witness test for a gas ultrasonic flowmeter on a FPSO.

FMC Technologies supplied the subsea equipment for the field including subsea production trees, water injection trees, control modules, wellheads, manifolds and other equipment.

Aptomar provided field monitoring services at Knarr field.