Madsen is a past-producing mine located in the Red Lake Gold District of northwestern Ontario, Canada. Historically, the mine has produced around 2 million ounces of gold.

The mine is currently owned by West Red Lake Gold Mines, a publicly traded gold company which is focused on redeveloping the property as its flagship project.

The company acquired the property in June 2023 from PureGold by purchasing all of the outstanding shares of Pure Gold Mining.

West Red Lake Gold announced positive pre-feasibility study (PFS) results for the gold mine in January 2025. The company aims to restart and commence production from the fully permitted Madsen from the second quarter of 2025.

According to the PFS report, the project can deliver 67,600oz. of gold annually over six years of full production. The mine life is estimated to be 7.2 years, with substantial upside potential.

Initial capital will be around C$44.1m ($30.92m), which is low as activities necessary to recommence operations at site are well advanced or complete.

In October 2024, West Red Lake secured funding commitments of more than C$68m for the restart.

Life-of-mine capital costs are expected to total C$502.9m ($352.61m), including C$45.3m contingency and C$9.1m closure costs. Project operating costs total C$588.1m.

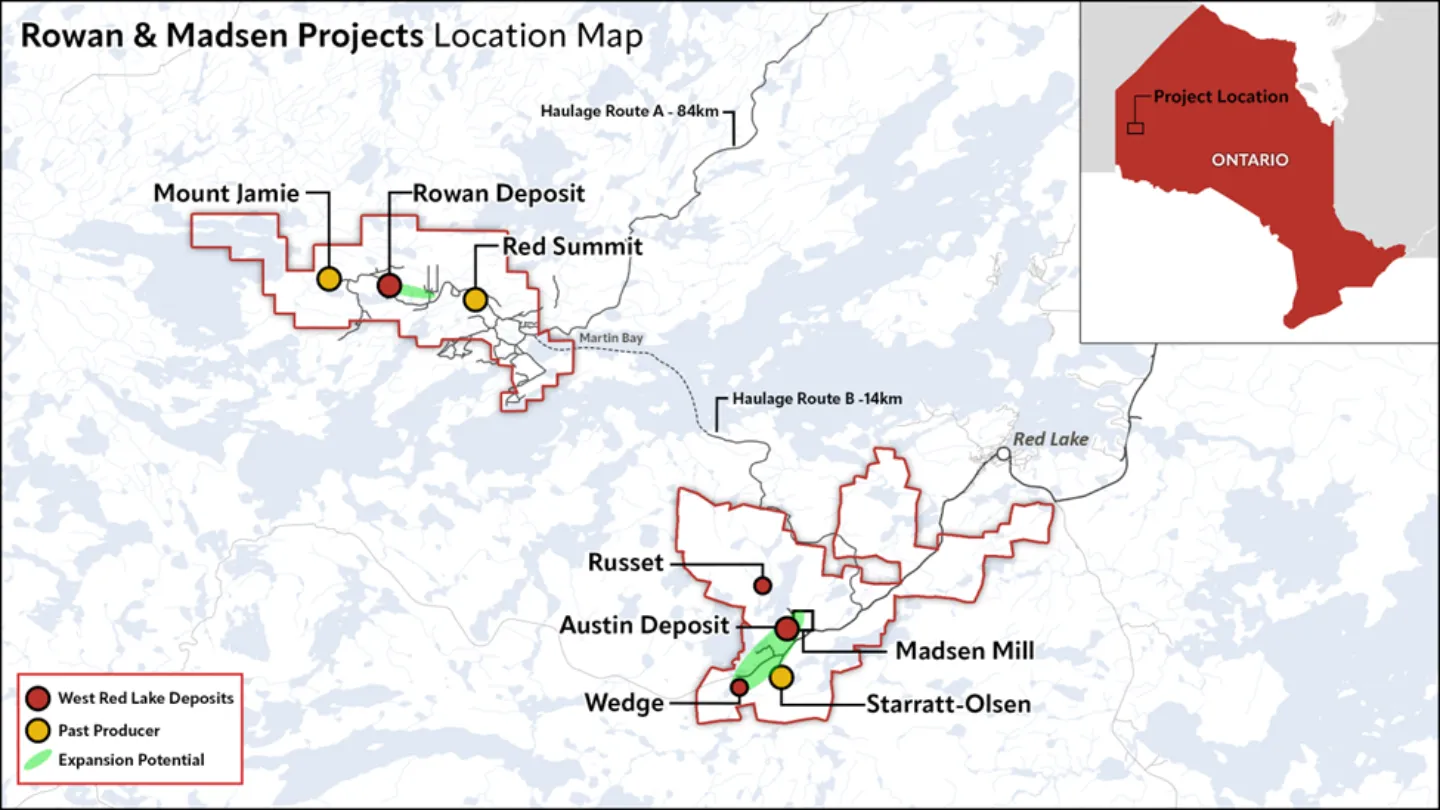

Madsen Mine Location

The Madsen Mine is situated within the Baird, Heyson and Dome Townships of the Red Lake Mining District.

The site is approximately 565km by road northwest of Thunder Bay in Ontario and around 475km by road east-northeast of Winnipeg, Manitoba.

Madsen can be accessed from Red Lake via Highway 618, with logging roads and winter trails branching providing further access to other portions of the property.

Overall, the mine includes a contiguous group of 241 tenures with a total area of 4,648 hectares.

Geology and Mineralisation

The Madsen Mine is situated in the western region of the Archean Superior Province within the Canadian Shield. It lies within the Uchi domain, which is composed of Mesoarchean and Neoarchean volcanic and plutonic rocks.

Supracrustal rocks from the Balmer, Confederation, and Huston assemblages are located beneath the mine property.

The older rock formations were intruded by different plutonic bodies, including the post-tectonic Killala-Baird batholith to the west and the syn-kinematic Dome and Faulkenham Lake Stocks to the east, along with smaller associated sills and dykes.

Gold mineralisation at the Madsen Mine is primarily concentrated in the Austin, South Austin, and McVeigh zones. These zones, along with the 8 Zone, form the Madsen deposit.

Gold distribution within these structures is predominantly confined to altered basalt and is more concentrated near key lithological contacts, such as ultramafic sills, felsic dykes, and felsic volcanic layers.

The mineralisation controls at Madsen Mine align with characteristics typical of an orogenic gold system. Recent studies show that the Madsen Mine exhibits many features of classic orogenic gold deposits, exhibiting similarities with the Red Lake Mine deposit.

Madsen Mine Reserves

The Madsen Mine project contains probable reserves of 1.823 million tonnes grading 8.16 g/t gold, with contained metal totalling 478,000 oz. of gold.

The mineral resource estimate for the mine includes an indicated resource of 6.9 million tonnes grading 7.4 g/t gold hosting 1.65 million troy oz. gold.

Inferred resource at the property is estimated to be 1.8 million tonnes grading 6.3 g/t gold containing 366,200 troy oz. gold.

Mining and Production

Historic underground workings at Madsen extends 2.3km in length with a depth of 1,300m. A substantial portion of the high-grade mineral resources lies near these historic workings and is considered suitable for remnant mining.

Modern mechanised cut-and-fill (MCF) mining and ground support techniques will enable safe extraction of some of these remaining resources.

Additionally, the mine contains mineral deposits in unmined areas, although these are considered lower in grade than the historically mined core zones.

Several underground mining methods were assessed based on varying geological conditions across the site.

The final selection includes Longitudinal Retreat Longhole (LH) with ramp access (32.7% of production); Mechanised Cut and Fill (MCF) with ramp access (60.6%) and Mechanised Drift and Fill (MDF) with ramp access for 8 Zone (6.5% of production).

The East and West ramp systems provide access to the mine, while a link is being built to connect them. This connection is scheduled for completion in Q1 2025. The ramp infrastructure is designed to accommodate modern 40-tonne haul trucks.

By early Q2 2025, the mine is expected to have 56 pieces of underground mining equipment in operation, increasing to 70 units by early 2026.

The workforce at Madsen Mine is projected to average 221 underground personnel over the life-of-mine (LOM) plan. Labour demand is expected to peak in Q4 2025 as the mine reaches full production.

Operations will stabilise between 2026 and 2028, with a gradual workforce reduction beginning in 2029 as lateral development requirements decrease.

Processing

The processing plant at Madsen Mine is designed to handle 800 tonnes per day (t/d) using a conventional Leach – Carbon in Pulp (CIP) process.

The facility includes a one-stage semi-mobile jaw crusher for primary crushing; an existing SAG mill and ball mill for grinding; and two gravity concentrators with an intensive leach system.

Pre-leach preparation involves thickening to 50% solids, which is followed by a pre-oxidation stage. The leaching and CIP circuit consists of five leach tanks and six carbon-in-pulp tanks.

A 1-tonne carbon plant is used for gold recovery and then it is refined to produce doré bars.

Cyanide destruction is managed using two tanks, with one on standby, and processed tailings are pumped to the tailings management facility (TMF).

The crushing circuit is designed to operate at 50% availability, while the milling, leaching, and gold recovery circuits will have an operational availability of 95%.

Based on metallurgical testing and the 2024 mine plan, the estimated LOM gold recovery rate is 95.7%.

Infrastructure at Madsen Mine

The Madsen Mine has an existing underground mine, mineral processing facilities, a shaft, two access portals, a water treatment plant, a tailings storage area, a rock dump, and a general services zone.

As part of the restart, some additional surface infrastructure will be introduced including a new mine dry facility and a mobile crushing unit.

The gold mine is connected to the northwest Ontario power network via aerial distribution lines, receiving 44kV electrical supply with a 12MW capacity.

The regional power grid is owned and operated by Hydro One.

For underground communications, Madsen Mine is equipped with a leaky feeder system, which will be extended to new working areas as mining operations expand.

Tailings will be stored on storage in the TMF and underground as hydraulic backfill.

Contractors Involved

The technical report and prefeasibility study for the Madsen mine were prepared by SRK Consulting (Canada).

Several other entities also contributed- Mining Plus on mine design and scheduling; Allnorth Consultants on infrastructure; Nordmin Engineering on shaft design and material handling and T Engineering on backfill.

Fuse Advisors assisted with metallurgy, processing, and recovery, while Knight Piésold Consulting advised on water and waste management.