The Makuutu Rare Earths Project is an ionic adsorption clay (IAC) hosted rare earth element (REE) deposit being developed around 120km east of Kampala in eastern Uganda.

Uganda-based private company Rwenzori Rare Metals (RRM) fully owns and operates the Makuutu project.

Ionic Rare Earths (IonicRE) has 51% interest in RRM. It will increase its ownership to 60%, subject to the completion of a feasibility study.

The Scoping Study of the Makuutu Rare Earths Project was completed in April 2021. In October 2022, Uganda’s National Environmental Management Authority (NEMA) approved the Environmental and Social Impact Assessment (ESIA) for the project.

The Mining Lease Approval is expected in the first quarter of 2023.

Makuutu Rare Earths Project has a Mineral Resource Estimate (MRE) of 532 million tonnes @ 640 ppm total rare earth oxide (TREO), at a cut-off grade of 200 ppm TREO- Ceric oxide (CeO2).

The scoping study has confirmed a base case 11-year critical rare earth oxide (CREO) and heavy rare earth oxide (HREO) production potential at the site, while potential life of the mine exceeds 30 years.

First production from the mine is expected in the first half of 2024, subject to environmental permissions and development approvals.

Location and site details

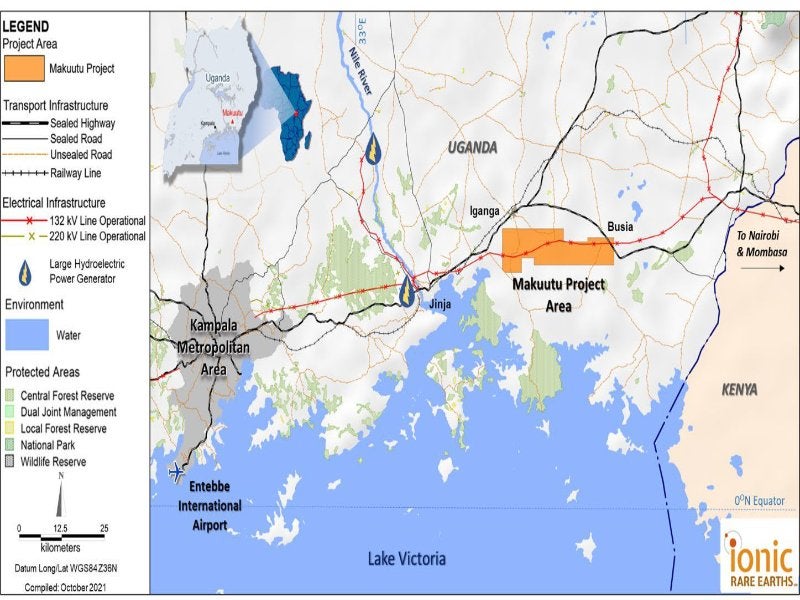

The Makuutu Rare Earth Element (REE) project is located around 40k east of Jinja, 120km East of Kampala in Eastern Uganda.

The site includes six licences including three Retention Licences (RL00007, RL1693 and RL00234) and three Exploration Licence (EL00147, EL00148 and EL00257), covering a combined area of about 298km².

The project site is surrounded by existing infrastructure including roads, rail, power infrastructure and cell communications.

Geology and Mineralisation

According to the project scoping study, the Makuutu resource stretches more than 20km, with a potentially mineralised basin extending up to 37km in length.

It has proven its potential to be a long life, low-cost capital source of magnet and heavy REEs.

The IAC-type REE property is said to be similar to those found in southern China, Myanmar, Madagascar, Chile and Brazil. The shallow deposit has less than 3m of cover across a 9m average thickness clay and saprolite zone.

Mineralisation occurs within the tropical lateritic weathering profile of a basin featuring sedimentary rocks such as shales, mudstones and sandstones. These rocks are considered the original source of the REE.

The REE mineralisation is concentrated in the weathered profile after dissolving from its primary mineral form such as monazite and xenotime.

Subsequently, it ionically bonded (adsorbed) or colloidally bonded on to fine particles of aluminosilicate clays like kaolinite, illite, smectite.

This adsorbed and colloidal REE will be extracted for production of rare earth oxide (REO).

Reserves

In May 2022, IonicRE announced a nearly 70% increase to the total mineral resource estimate (MRE) of Makuutu project.

The updated MRE is estimated at 532 million tonnes at 640ppm Total Rare Earth Oxide (TREO), above a cut-off grade of 200 parts per million (ppm) TREO minus CeO2.

The Indicated resource estimate increased 512% to 404 million tonnes at 670 ppm TREO.

The updated resource estimate made Makuutu one of the world’s largest ionic adsorption clay (IAC) deposits.

The MRE is based on data procured from 11 low plateaus defined by radiometric eU/eTh anomalism on mineral retention licences RL00007, RL1693 and RL00234. The tenements cover 134km2 of the 298km2 project.

Mining

The Makuutu project is expected to be mined using standard equipment and methods. It will primarily involve conventional truck and shovel, open pit mining at an appropriate bench height.

The metallurgical test work at the property achieved metallurgical recoveries of up to 75% TREE-CeO2 (Total Rare Earth minus Cerium) using simple extraction techniques.

In addition, the project has the potential to produce scandium as a co-product.

During mining operations, a pre-strip of 1m of topsoil will be stockpiled. The lower recovered rare earth grade open pit material will be stockpiled adjacent to the pit, while the waste will be mined and paddock dumped adjacent to the pit.

The material will be hauled to the Run-of-Mine (ROM) pad, fed into the process plant or stockpiled.

The processing is planned through simple acidified salt desorption heap leached using ammonium sulfate to break the chemical ionic bond which washes the rare earths from the ore into a pregnant leach solution (PLS).

The PLS is then concentrated using membrane technology, from which the rare earths are precipitated as a mixed rare earth carbonate product.

After extraction, the residue will be washed to recover residual reagents and REE content. The tailings will be returned to the mined open pits.

The mine planning activities assessed scenarios including Run of Mine (ROM) options from 2.5 to 12.5 million tonnes per annum (Mtpa), with smoothed total material movements (TMM) up to 25 Mtpa.

Around 84.5Mt will be mined at an average grade of 810ppm TREO, which will deliver a mine life of 11 years.

Contractors involved

IonicRE worked with several industry consultants to complete technical and commercial studies in support of the Makuutu Scoping Study.

This includes Atacama Consulting; GJ Exploration; Environment Plus; JBN Consults and Planners; Chimerical Technology; ALS Metallurgy; Cube Consulting; Libertas Infinity; ADT Africa; NewPro Consulting and Benzu Minerals.

In April 2021, IonicRE signed a non-binding memorandum of understanding (MoU) with Aluminum Corporation of China’s (Chinalco) subsidiary, China Rare Metals and Rare Earth (Jiangsu) to advance the development of the Makuutu project.

The MoU may also lead to investment in IonicRE, and/or the Makuutu Rare Earths Project directly, as well as offtake agreements for rare earth product in future.