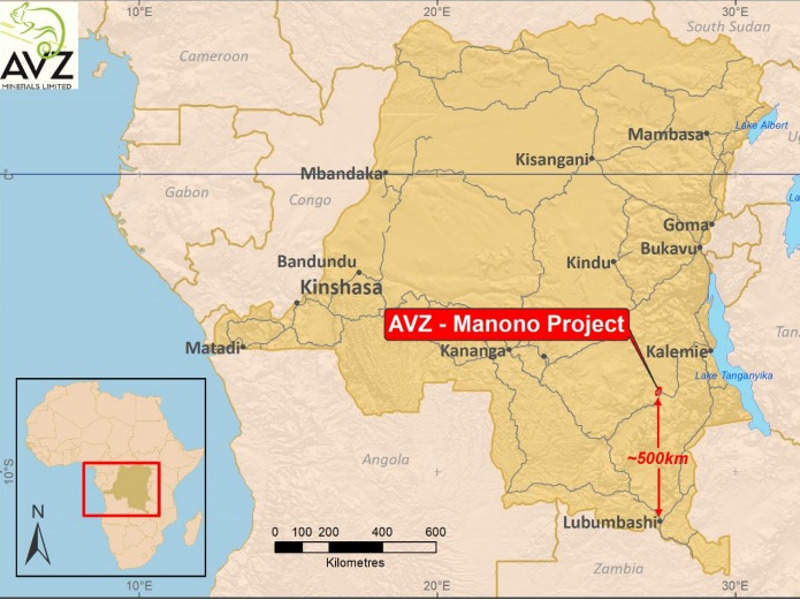

Manono lithium project is an open-pit mine located 500km north of Lubumbashi in the Democratic Republic of Congo (DRC).

The mine is owned jointly by AVZ Minerals (60%), La Congolaise D’exploitation Miniere (30%), and Dathomir Mining Resources (10%). The contingency cost of the project is estimated to be $36m.

Manono is a historic mine, which was mined for tin between 1919 and 1982.

AVZ holds two granted exploration permits for the extension of the Manono project, namely SW and NW extension targets.

The mine is expected to produce 440,000 tonnes per annum (tpa) at a minimum of 5.8% Li2O concentrate over its mine life of 20 years. The annual throughput rate is anticipated to be two million tonnes per annum (Mtpa) of pegmatite.

Scoping study for the Manono project was released in October 2018, while the full feasibility study (FFS) is scheduled for completion in the second quarter of 2019. Construction is expected to commence in the fourth quarter of 2019, while commissioning is scheduled for the second quarter of 2020.

Geology and mineralisation

The project area lies within the mid-Proterozoic Kibaran Belt. Lithium and tin mineralisation occurs in the Lithium Caesium Tantalum (LCT) pegmatites, between the sequences of chlorite schist.

The pegmatites are mostly found in the Manono and Kitotolo regions, where primary mineralisation is hosted in the Roche Dure pegmatites of the area.

Manono mine reserves

As of August 2018, the Manono mine was estimated to contain measured, indicated and inferred mineral resources of 259Mt grading 1.63% Li2O, 219kt of tin as cassiterite and 11.2kt of Tantalum.

Mining and processing at Manono lithium project

Conventional open-cut method will be used to recover lithium from the Manono mine. The ore will be blasted and transported by trucks to the processing plant located 1.5km away from the mine.

The ore will be processed by a three-stage crushing and screening circuit integrating a tertiary crusher equipped with high-pressure grinding rolls (HPGR) technology. It will then be sent to a ball milling and classification circuit, and magnetic separation circuit.

The crushed ore will pass through a series of flotation stages including roughing and cleaning, which will produce a spodumene flotation concentrate from the scalping screen fines.

The obtained concentrate will then undergo thickening and pressure filtering process followed by thickening of the tailings before reaching the tailings storage facility (TSF). The TSF will be located in the area near the existing waste dumps.

A fleet of public and private barges with a maximum loading capacity of 1,000t will be used for transportation. The dry spodumene will be loaded in tipping containers by front-end loading and transported by truck to Dar es Salaam in Tanzania.

Infrastructure at Manono mine

The project will require 9MW of power, which will be supplied by onsite diesel-fuelled generators. Local fuel storage is also planned to be set-up on-site. Dathomir will rehabilitate the Piana Mwanga hydroelectric power station and a road between Lubumbashi and Manono. Water will be supplied from Lake Lukushi’s existing dam.

Existing access roads are planned to be renovated, while a satellite and mobile tower will be raised on the site for on-site communication.

An existing camp is also available on the site, which can be used for construction works, while new accommodation facilities will be constructed for employees.

The site administration facilities to be built near the entrance of the processing plant include offices, meeting rooms, a training facility, and lunchrooms. The existing administration office on-site is also operational. Other facilities will include workshops, laboratory and storage spaces.

Contractors involved

MSA Group carried out the maiden mineral resource estimate of the Manono mine.

CPC Project Design managed and completed the scoping study. CPC was also involved in developing the processing plant engineering design, and operating cost and capital cost estimates for the project.

Alan Dickson and Associates was involved in financial modelling of the project for the scoping study, while Nagrom worked on the metallurgy of the project.

A drilling contract was signed between AVZ and Equity Drilling for drilling operations at the project, in October 2017.

Off-take agreements

AVZ Minerals signed a memorandum of understanding (MOU) with Shanghai Greatpower Industry for the off-take from Manono lithium project, in 2017.

In March 2018, Guangzhou Tinci Materials Technology (Tinci), which is the world’s biggest lithium-ion battery electrolyte manufacturer, and Beijing National Battery Technology signed off-take agreements with AVZ Minerals.