Marathon Project is a large undeveloped copper-palladium deposit located in Northwestern Ontario, Canada.

The project is owned by Toronto Stock Exchange-listed company Generation Mining.

In January 2020, the company announced a positive preliminary economic assessment (PEA) study on the Marathon project. This was followed by the release of a feasibility study in 2021.

In March 2025, Generation Mining released an updated Feasibility Study, which replaced Amended Feasibility Study Update on the project filed in May 2024.

According to the latest report, the polymetallic deposit can produce 42 million pounds (Mlbs) of copper, 168 thousand ounces (koz) of palladium, 38 koz platinum, 12 koz gold and 240 koz silver annually over nearly 13 years of mine life.

The initial capital costs for construction and ramp-up, excluding sustaining capital and closure costs, is estimated to be C$992m ($689m).

Marathon Project is also expected to create more than 800 jobs during construction and around 400 direct permanent jobs during operations.

Generation Mining has also received key permits required to begin construction.

As of April 2025, it awaits the Lakes and Rivers Improvement Act (LRIA) approvals from Ministry of Natural Resources (MNR) for the construction of tailings and water management structures on site; and Environmental Compliance Approval – Waste (ECA-W ISW) from the Ministry of the Environment, Conservation and Parks (MECP) for the discharge of water at the project site.

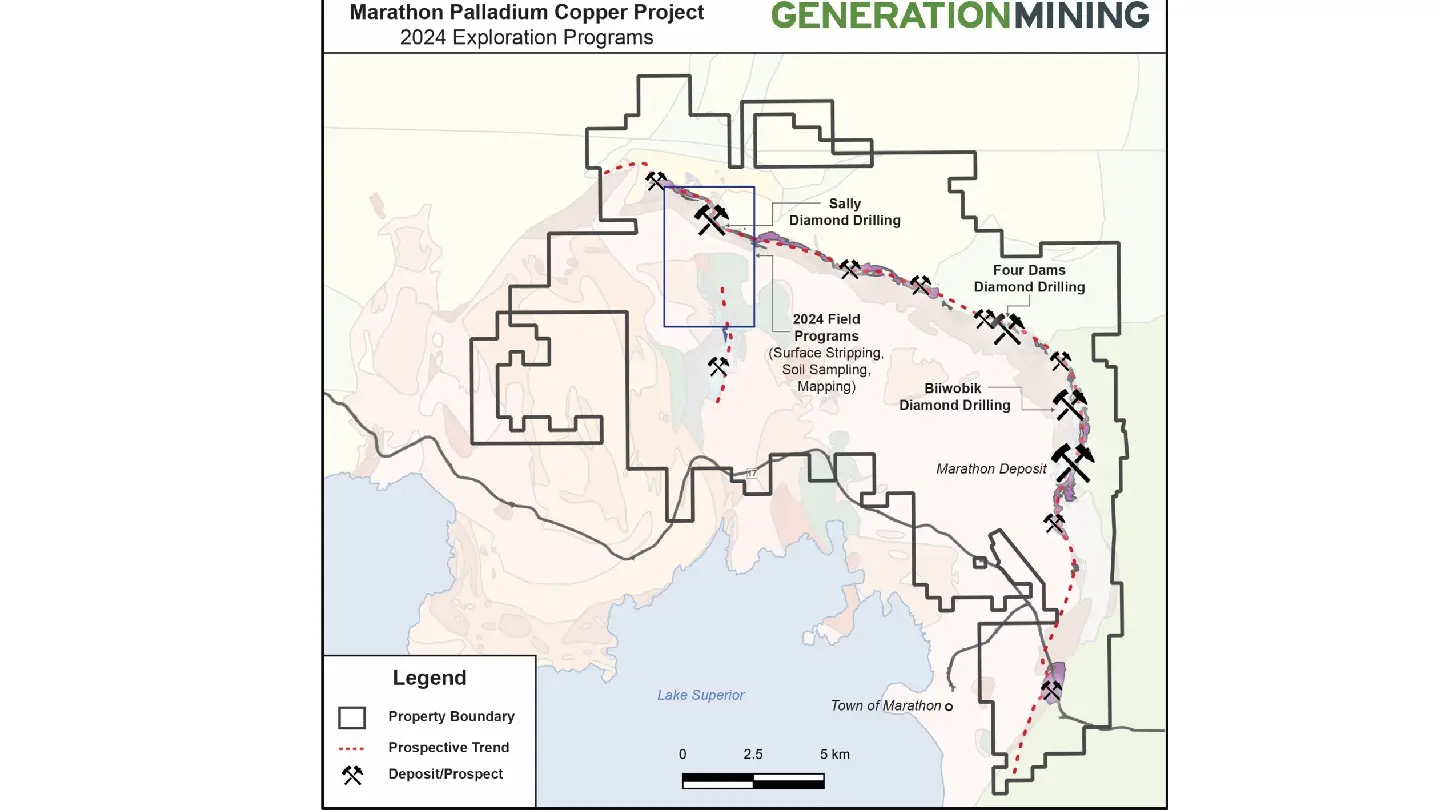

Marathon Project Location

The Marathon Project is located about 10km north of the town of Marathon in Ontario, next to the Trans-Canada Highway No. 17, along the northeastern shore of Lake Superior.

Thunder Bay, a key industrial hub, lies roughly 300km to the west via Highway 17.

The site covers an area of 21,883 hectares, comprising 46 leases and 933 claim cells.

History

The Marathon Property has been explored for more than 60 years. Around 193,057m of drilling at the property is completed.

The property went through multiple ownership changes. Gen Mining entered the project in July 2019 by acquiring a 51% stake from Stillwater Canada and forming a joint venture.

In November 2020, Gen Mining increased its interest to 80%. After Sibanye Stillwater declined to continue funding, Gen Mining acquired the remaining stake, gaining full ownership in January 2022.

The company entered into a Precious Metal Purchase Agreement with Wheaton Precious Metals in December 2021 for $240m.

The property has no prior history of mining.

Geology and Mineralisation

The Marathon property lies along the eastern margin of the Proterozoic Coldwell Complex, part of the Keweenawan Supergroup.

The Marathon deposit is hosted in the Two Duck Lake Gabbro, a late-stage intrusive phase of the Eastern Gabbro, which intrudes the older Archean Schreiber-Hemlo Greenstone Belt. The deposit features several broad, continuous zones of disseminated sulphide mineralisation occurring as shallow-dipping, sub-parallel lenses along the basal contact of the gabbro. These include the footwall, main, hanging wall, and W-Horizon zones, with the Main Zone being the thickest.

Sulphide minerals include chalcopyrite, pyrrhotite, bornite, pentlandite, cobaltite, and pyrite.

The deposit is interpreted as forming from sulphide accumulation in magma conduits, with metal enrichment through multi-stage dissolution, similar to Noril’sk-type systems.

Beyond the Marathon deposit, the property hosts additional PGM mineralisation at Geordie, Sally, Boyer, and Four Dams.

Marathon is part of the Mid-Continent Rift System, which includes other significant mafic-ultramafic hosted deposits such as Eagle (Yellow Dog peridotite), Tamarack, Thunder Bay North (Current Lake), and the Duluth Complex intrusions.

Marathon Project Mineral Reserve Estimate

The Marathon Project hosts total Proven and Probable open pit mineral reserves of 128.3 million tonnes (Mt), grading 0.64 g/t palladium (Pd), 0.21% copper (Cu), 0.20 g/t platinum (Pt), 0.07 g/t gold (Au), and 1.7 g/t silver (Ag).

This equates to contained metals of approximately 2.63 million ounces of palladium; 605 million pounds of copper; 815 thousand ounces of platinum; 291 thousand ounces of gold; and 6.88 million ounces of silver.

Mining and Recovery

Mining at the Marathon Project will use conventional open-pit methods, with operations slated to commence 24 months before the process plant starts up and will continue for approximately 13 years.

Ore and waste will be mined in 10m benches, with the ability to flitch mine in 5m intervals where finer grade control is required. Pit designs will use a double benching system, with 20m spacing between berms.

The mining fleet will include diesel-powered rotary drills for bulk drilling, DTH drills for highwall areas, large hydraulic shovels, wheel loaders and smaller excavators. Haulage will be conducted using rigid-frame trucks.

Potentially acid-generating (PAG) waste rock will be stored sub-aqueously in the tailings facility or backfilled into mined-out pits. Lower-grade ore not immediately processed will be stockpiled for later use, allowing higher-grade material to be prioritised earlier in the mine life. Stockpiled material will be re-handled to the crusher as needed.

The process plant is designed to treat 10.1 million tonnes of ore per year, with a ramp-up over the first two years. Run-of-mine ore will be transported to a primary crusher located southwest of the pit, within 2km of the pit rim, or stockpiled northeast of the crusher.

Waste rock will be placed in nearby storage areas (MRSA), used as backfill in mined-out pits, or utilised as construction material for a tailings dam located 3–4 km southwest of the pit.

The processing plant will use a conventional SAG and ball mill (SAB) comminution circuit. A pebble crusher will be added after the initial capital phase to help achieve full throughput.

Following grinding, ore will pass through a flotation circuit consisting of rougher flotation, regrinding of the concentrate, and a three-stage cleaning circuit.

Final processing includes concentrate dewatering and tailings disposal. The plant will produce a copper- Platinum Group Metals (PGM) concentrate for off-site shipment.

Contractors Involved

The 2025 Feasibility Study was prepared by Ausenco Engineering Canada.

Moose Mountain Technical Services, Knight Piésold, P&E Mining Consultants and JDS Energy and Mining also contributed.