Morelos Complex in Mexico is the principal asset of Canada-based intermediate gold producer Torex Gold Resources. The project includes the El Limón Guajes (ELG) Mine Complex, the Media Luna Mine, the EPO deposit, a processing plant, and associated infrastructure.

Construction works for the ELG Mine Complex began in October 2013 following the completion of the feasibility study in 2012. It commenced commercial operations in April 2016.

Torex integrated the EPO underground deposit into Morelos Mine Plan in September 2024 after completion of an internal pre-feasibility study on the deposit.

The Media Luna Mine is an underground deposit containing gold, copper, and silver mineralisation. The mining project was approved by the company in March 2022. It produced first copper concentrate in March 2025.

The Media Luna Project feasibility study results were incorporated into an updated Technical Report for Morelos Complex. The report, published in March 2022, includes a comprehensive life of mine (LOM) plan and economic analysis for both the ELG Mine Complex and Media Luna.

Morelos Complex has a LOM of 11.75 years, starting from April 2022 and ending in Q4 2033. The development of Media Luna Project entailed an investment $848m.

Morelos Property Location

Torex owns the Morelos Property through its Mexican subsidiary Minera Media Luna. The property is situated within in the Mexican State of Guerrero, approximately 180km southwest of Mexico City.

As a group of seven mineral concessions, the property includes an area of nearly 29,000 ha. This includes the Reducción Morelos Norte Concession that hosts four deposits- El Limón (which includes El Limón Sur), Guajes (together, referred to as the ELG OP), Sub-Sill and ELD and Media Luna.

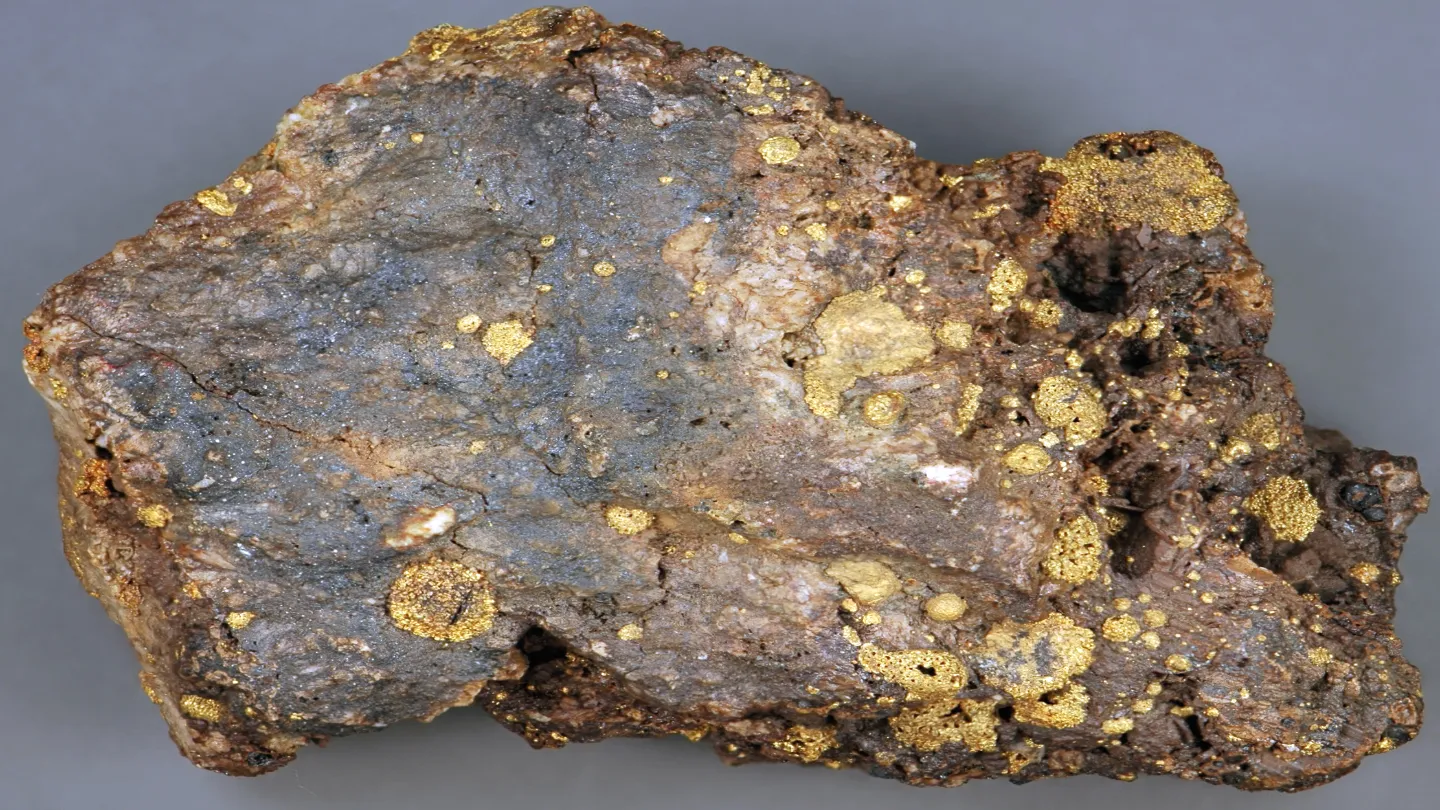

Geology and Mineralisation

The Guerrero platform consists of a thick Mesozoic carbonate sequence, including the Morelos, Cuautla, and Mezcala formations, intruded by early Tertiary-age granitoid bodies.

The Morelos Complex features a structurally complex sequence of marble, limestone, shale, and sandstone formations, intruded by the El Limón granodiorite stock, followed by felsic dykes and sills. At El Limón, gold mineralisation is hosted in a skarn body along a 2km corridor at the northeast contact of the granodiorite stock. The El Limón Sur zone, 1km south, follows a steep ridge toward the Balsas River and shares similar stratigraphy with the southeastern El Limón deposit.

The Sub-Sill zone, located between El Limón and El Limón Sur, lies beneath the El Limón sill. Multiple skarns occur along the contacts between carbonate-rich sediments, marbles, and granodiorite sills extending from the main intrusion. High-grade gold mineralisation is mainly linked to exoskarns with retrograde alteration.

The Guajes East zone, developed in the same lithologies as El Limón but on the opposite side of the intrusion, hosts a 300m-wide, up to 90m-thick skarn, extending at least 600m along the northwest intrusion edge. The Guajes West zone, at the northwest contact of the granodiorite stock, exhibits a hornfels–intrusive contact with localised, structure-controlled skarn occurrences.

The ML deposit, 7km south of the ELG Mine Complex, lies in Morelos Formation limestone, intruded by feldspar porphyry dykes and sills. Drilling has defined a gold-copper-silver mineralised skarn spanning 1.4km by 1.2km, with thicknesses from 4m to over 70m. Skarn alteration and mineralisation remain open to the southeast, southwest, west, and northwest.

Morelos Complex Mineral Reserves

The mineral reserve statement indicates a total of 40,871kt of Proven and Probable reserves, with an average gold, silver, and copper grades of 2.90 g/t Au, 16.3 g/t Ag, and 0.55% Cu, containing approximately 3,817 koz of gold, 21,442 koz of silver, and 495 Mlb of copper.

Measured and indicated mineral resources are estimated to be 46.7Mt at average grades of 3.41 g/t Au, 19.6 g/t Ag, and 0.66% Cu and containing 5.1 Moz of gold, 29.3 Moz of silver and 677Mlb of copper.

Inferred Mineral Resources total 16.2Mt at 2.17 g/t Au, 25.5 g/t Ag, and 0.95% Cu and containing 1.13 Moz of gold, 13.3 Moz of silver and 340 Mlb of copper.

Mining at Morelos Complex

The ELG open-pit (OP) operation employs a conventional truck-and-shovel mining method. The El Limón and Guajes pits are mined using the Owner’s fleet with contractor maintenance and specialised support, while the El Limón Sur pit is fully operated by contractors.

The ELG underground (UG) operation, covering the El Limón and Sub-Sill deposits, uses a cut-and-fill mining method with consolidated rockfill backfill. Mining is carried out by contractors under the Owner’s supervision and Technical Services.

The ML Underground mine is designed for a 7,500t/d production rate, primarily using longhole stoping with paste backfill, supplemented by mechanised cut-and-fill stoping. The mine will be fully mechanised, with primary access via the 6.5km Guajes Tunnel, linking ML to the ELG Mine Complex, which will remain the operational base.

ML mining will occur across six active blocks, each with dedicated infrastructure for continuous ore production. The deposit’s dip allows for efficient material movement through sub-vertical ore and waste passes.

A paste backfill plant, located outside South Portal Upper, will receive slurry tailings from ELG’s processing facility via the Guajes Tunnel. The paste will be pumped into underground stopes via a borehole and distributed through underground piping.

ML operations will be Owner-operated with contractor support, transitioning open-pit personnel to underground roles as open-pit mining ceases. The mobile fleet will be a mix of Battery-Electric Vehicles (BEVs) and diesel equipment, with BEVs reducing ventilation needs, improving working conditions, and supporting carbon reduction goals.

Mineral Processing and Recovery

The ELG Process Plant was expected to continue processing ELG OP and UG ores until Q3 2024. A new processing facility will be commissioned to handle high-grade copper sulphides from ML ores, improving gold and silver recovery and enabling the production of saleable copper concentrate.

The ELG Processing Plant, operational since late 2015, has processed over 24.4Mt of ore, yielding more than 2.2 Moz of gold by December 2021.

Cyanide leaching with carbon-in-pulp (CIP) adsorption remains effective for ELG OP ores. However, high iron content in feed has increased cyanide consumption, mitigated through pre-oxidation using liquid oxygen injection. The SART plant, introduced in 2018, has further reduced cyanide consumption by recovering 89.1 t/month of copper.

ML ores, containing significant copper as chalcopyrite, will be processed via flotation, with copper accounting for nearly 30% of the ore’s economic value. Extensive metallurgical testing on infill drill core samples has optimised conditions for maximising copper concentrate grade and gold and silver recovery, while assessing deleterious elements (bismuth, arsenic, zinc, cadmium) that will incur smelter penalties.

The preferred ML processing method involves sequential flotation, recovering a saleable copper concentrate first, followed by an iron sulphide (Fe-S) concentrate. Reactive pyrrhotite in ML ores, known to increase cyanide consumption and reduce gold recovery at ELG, will be managed by separately floating iron sulphides and regrinding them before leaching. This approach reduces cyanide consumption and improves gold recovery, as finely ground iron sulphides (80% passing 30 µm) leach more efficiently than the current grind size (80–100 µm).

Laboratory tests suggest ML and ELG UG ores will achieve recoveries of 93.0% for copper, 90.0% for gold, and 86.0% for silver in an integrated flotation and leaching circuit.

The new flowsheet will maximise reuse of existing infrastructure to minimise capital costs. The crushing and primary grinding circuits will remain largely unchanged, while a new flotation circuit will produce three flotation products. Copper concentrate will be filtered and trucked off-site for smelting. The iron sulphide flotation circuit will generate low-sulphur tails for leaching in the existing gold recovery circuit, while high-sulphur iron sulphide concentrate will be reground and leached separately in repurposed tanks.

The resulting gold- and copper-rich solution will be processed through the SART plant, which will recover copper and silver while regenerating cyanide. The gold-bearing product will then proceed through the modified CIC circuit to the ADR plant for final recovery.

Contractors Involved

The ELG Mine Complex Life of Mine Plan and Media Luna Feasibility Study, published in 2022, was prepared by Torex with the contribution of several authors. This includes M3 Engineering & Technology Corporation; SLR Consulting; Consultoria e Ingenieria ProMet101; BQE Water; BBA E&C; Stantec Consulting International; Paterson & Cooke Canada.

Golder Associates; JDS Energy & Mining; Call & Nicholas; NewFields Mining Design & Technical Services and Conrad Partner also contributed.