The Munglinup graphite project is a high-grade open-pit graphite mine located in the South Coast of Western Australia. The joint venture (JV) of MRC Graphite (MRCG), a subsidiary of Mineral Commodities (MRC), and Gold Terrace is developing the project, under an agreement signed in November 2017.

MRC is acting as the project operator on behalf of the JV and holds 51% share in the project, while Gold Terrace holds the remaining stake.

Pre-feasibility study (PFS) of the project was completed in May 2018, while definitive feasibility study (DFS) is anticipated to be completed in December 2019. Graphite production from Munglinup is expected to be commenced by the end of 2019.

Munglinup is estimated to require a capital expenditure of A$52.4m ($39.4m) to be developed. It is anticipated to produce 54,800 tonnes per annum (tpa) of high-quality graphite concentrate over a mine life of nine years.

Munglinup graphite project location, geology, and mineralisation

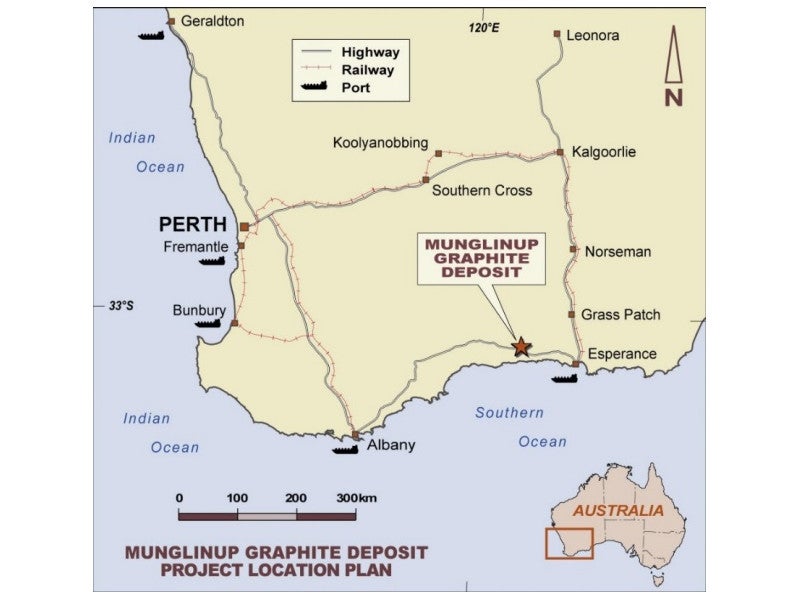

The Munglinup graphite project is located approximately 3km from Munglinup town and 105km from Esperance in Western Australia. The site is situated within the R24714 mining reserve and is covered by M74/245 and E74/565 tenures.

The graphite deposits at Munglinup were subject to multiple exploration activities by several companies and prospectors over the last 100 years.

The project area comprises Archean to Paleoproterozoic, metamorphosed granitic, and other metamorphic rocks of the Albany-Fraser Orogen, mostly gneiss and migmatite.

Graphitic mineralisation lies within the altered amphibolite and is associated with ferruginised zones, jaspilite, quartz veining, and magnesite.

Munglinup graphite project reserves

The proven and probable reserves of Munglinup graphite project are estimated to be 3.4 million tonnes (Mt) graded at 15.9% Total Graphitic Carbon (TGC).

Mining and processing at Munglinup graphite project

Conventional open-pit mining method, using trucks and excavators, will be applied at the Munglinup graphite deposit.

The proposed mining fleet will include 40t to 90t class excavators (Komatsu PC600 or equivalent) and 45t articulated all terrain dump trucks (Caterpillar 740 or equivalent).

The processing plant is capable of treating 400,000tpa of ore and will process ore using scrubbing, grinding, and graphite recovery through flotation.

Ore will be pumped to deslime cyclones, with the cyclones underflow forwarded to the flotation circuit that will comprise rougher flotation followed by five stages of regrind milling and cleaner flotation.

The high-grade graphite flotation concentrate will be filtered using a plate and frame filter and then dried. The product will be sized over multi-deck screens and transferred to a bagging machine for packing into 1t bags.

The bagged graphite concentrate will be transported to the Esperance Port in trucks for shipping to various markets.

Infrastructure

Power required for the project is proposed to be supplied by Horizon Power, the operator of the local grid network in the Esperance area.

Groundwater will be the main source of water for the project. Overflow from tails and concentrate thickeners of the processing plant will gravitate to the process water pond for re-use within the plant.

Contractors involved

MRC awarded the early contractor involvement (ECI) and front-end engineering and design (FEED) contracts to Mondium, a JV between Monadelphous and Lycopodium, in March 2019.

MRC prepared the project PFS with support from consultancies such as ALS Metallurgy, Australian Environmental and Mining Company (AEMCO), Battery Limits, Dajolin Mine Management Services, and Esperance Tjaltjraak Native Title Aboriginal Corporation.

Other parties involved in the project are Hastings Bell, Independent Energy Services, Integrate Sustainability, Klohn Crippen Berger, Mine Site Construction Services, and Rockwater.