Namdini gold project is a high-grade gold mine being developed in Ghana, West Africa, by Cardinal Resources.

Mining lease for the project was secured at the end of 2017 through Cardinal Resources’ local subsidiary, Cardinal Namdini Mining. The lease was granted by the Minister of Lands and Natural Resources, Ghana, as part of a large-scale mining license.

The pre-feasibility study (PFS) of the gold project was completed in September 2018, and the feasibility study (FS) is expected to be completed in the third quarter of 2019. The mine is estimated to produce approximately four million ounces (Moz) of gold through its life of 14 years.

Namdini gold project location, geology, and mineralization

The Namdini mining license is located 50km south-east of Bolgatanga in northern Ghana and lies 12km from Cardinal’s Ndongo east prospect.

The project falls within the Birimian Nangodi greenstone belt, which hosts sedimentary, granitic, and volcanic lithologies. Classified as an orogenic deposit, the gold mine has a strike length of 1,150m and a width of up to 300m.

The project comprises sharply-dipping, intensely-deformed sediments, which are intruded by a medium-grained granite and diorite. The southern part of the project is covered by flat-lying Volta basin clastic sedimentary rocks.

Gold mineralization at Namdini is contained within sheared and highly altered rocks containing sulfides, mainly pyrite with minor arsenopyrite.

Reserves

The Namdini project is estimated to contain 129.6 million tonnes (Mt) of probable ore reserves grading 1.14 g/t Au, while Contained gold is estimated to be 4.76Moz.

Mining at Namdini gold project

Conventional open-pit method of mining, including drilling, blasting, and hydraulic shovel operation followed by loading and hauling will be applied at Namdini.

The project will use 400t class excavators and 150t-class rigid body dump trucks supported by a fleet of dozers, graders, water carts, and utility vehicles.

Ore processing at Namdini

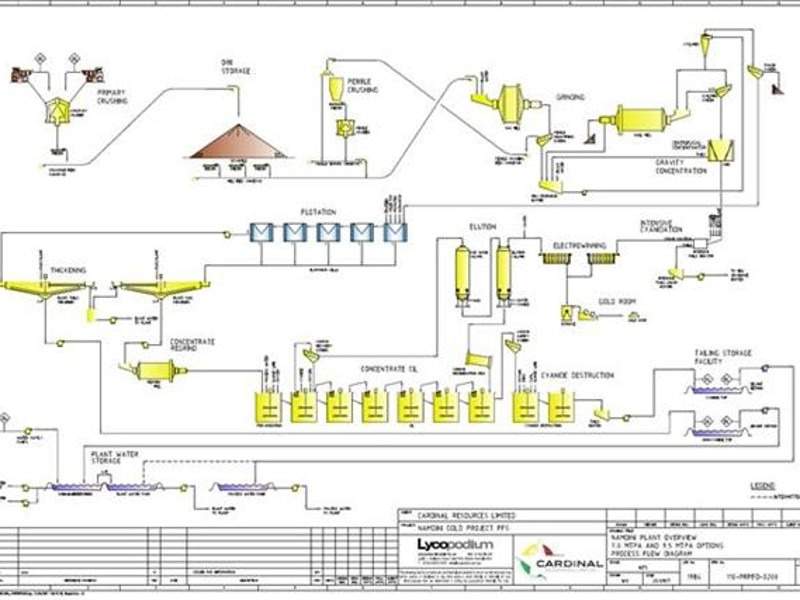

The ore will be processed at a 9.5Mtpa processing facility comprising a single-stage primary crusher to produce a P80 product size of 150mm. The crushed ore will be fed to a coarse ore stockpile via two apron feeders.

Ore will pass through two stages of grinding – semi autogenous (SAG) and ball milling in closed circuit with cyclones to produce a P80 grind size of 106µm.

The resultant product will be forwarded to a gravity recovery concentration circuit comprising a gravity scalping screen, a single centrifugal concentrator, and an intensive leach reactor.

From the concentrator, the product will be taken to rougher flotation circuit for producing a gold-rich sulfide concentrate. Just 10% of the concentrate will further undergo regrinding, followed by thickening to minimize carbon-in-leach (CIL) tankage and reduce overall reagent consumption.

The resultant product will pass through 3.5t split AARL elution circuit before undergoing electro-winning and smelting processes to recover gold from the loaded carbon and produce doré.

Infrastructure facilities

Access to the project area from Bolgatanga is through a sealed highway, followed by 20km of gravel roads.

Power for the project will be sourced from the national grid’s 161kV above-ground transmission line running approximately 30km west of the project site. A power line will be built under a build-own-operate (BOO) arrangement for securing the power supply.

Water required by the project will be collected from the White Volta River, located 7km from the site.

Contractors involved

Golder Associates calculated the ore reserves and drafted the mine design, while a company named Lycopodium was engaged for the process and infrastructure design and capital and operating costs.

MPR Geological Consultants was responsible for mineral resource estimates, while Knight Piesold was engaged for designing the tailings storage facility and associated infrastructure facilities as part of the PFS.

ALS Global conducted the metallurgical test works as part of the PFS, and the results were interpreted by Independent Metallurgical Operations.

Orefind conducted geology and structural genesis of the deposit, while NEMAS Consult is responsible for environmental works.