The Northern Lights project forms part of the Norwegian Full-Scale carbon capture and storage (CCS) project, which is one of the first industrial-scale, open-access projects in Europe to develop a value chain for CCS.

Supported by the Norwegian government, the feasibility studies for Norway’s flagship Full-Scale CCS project were carried out in 2016. The project involves CO2 capture from industrial sources in the Oslo-fjord region and its transportation and storage on the Norwegian Continental Shelf. The Norwegian state enterprise Gassnova is acting as the coordinator for the project.

The Northern Lights project is planned to be developed by a consortium of three international oil giants including Equinor, Shell, and Total.

The project partners reached an investment decision for the project in May 2020. The development and operation plans for the project which is estimated to involve £550m ($680m) of initial investment have also been handed over to Norway’s Ministry of Petroleum and Energy.

Subject to approval by the Norwegian authorities by 2021, the Northern Lights CCS project is expected to store approximately 1.5 million tonnes (Mt) of CO2 annually in phase one, starting from 2024 onwards.

Northern Lights CCS project background

The concept evaluation and the pre-feasibility study for the carbon capture and storage project were completed in 2015, while the feasibility studies were completed by the end of 2016. Shell and Total joined Equinor (formerly Statoil) as the partners for the Northern Lights project in September 2017.

Gassnova completed the front end engineering and design (FEED) studies for the CO2 storage project by September 2019.

The Northern Lights project partners completed the drilling of a confirmation well 31/5-7 Eos to a depth of 2,500m beneath the seabed of the Norwegian North Sea for injection and storage of CO2 in March 2020. It is the first well to be drilled in exploitation licence EL001 which was awarded to the Equinor-led consortium in January 2019.

The Northern Lights joint venture signed memoranda of understanding (MoU) with seven European firms including Air Liquide, Arcelor Mittal, Ervia, Fortum Oyj, HeidelbergCement, Preem, and Stockholm Exergi for the CCS project in September 2019.

Northern Lights CCS project details

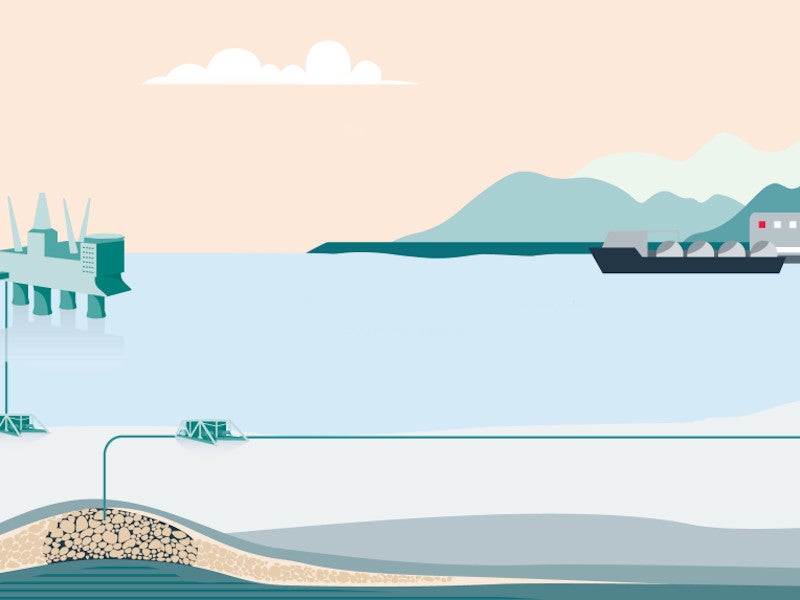

The CO2 will be captured from industrial capture sources including, Fortum Oslo Varme’s waste-to-energy plant at Klemetsrud and Norcem’s cement factory in Breivik.

The captured CO2 will be compressed and liquefied at the source sites and the liquefied CO2 will be transported by ship to an onshore receiving terminal in the Naturgassparken industrial area in the municipality of Øygarden, on the Norwegian west coast.

The CO2 receiving plant will be remotely operated from Equinor’s facilities at the Sture terminal in Øygarden and the subsea facilities from Oseberg A platform in the North Sea.

The liquefied CO2 from the onshore terminal will be transported through an offshore pipeline for injection and permanent storage in a reservoir approximately 2.5km beneath the seabed, located south of the Troll field in the North Sea.

The project will be capable of transporting and storing 1.5 million tonnes per annum (Mtpa) of CO2 in phase one. It can be further expanded up to 5Mtpa storage capacity in subsequent development phases.

Contractors involved

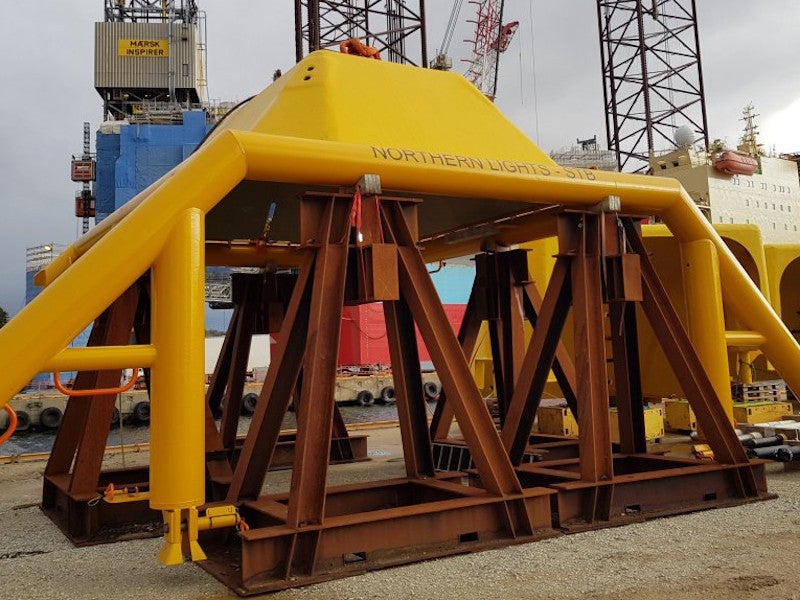

Aker Solutions was contracted for the supply of subsea infrastructure equipment for the early well development at the Northern Lights CO2 storage site in January 2019.

Ashtead Technology provided subsea installation monitoring services for early well development for the project.

KBR received the concept and FEED contract for the onshore CO2 storage terminal for the project in November 2017, while Multiconsult provided site-preparation and marine structures design for the terminal facility under a contract awarded in the same month in 2017.

Safetec was subcontracted by KBR to provide for the safety and efficiency related layout and design inputs for the project in April 2019.