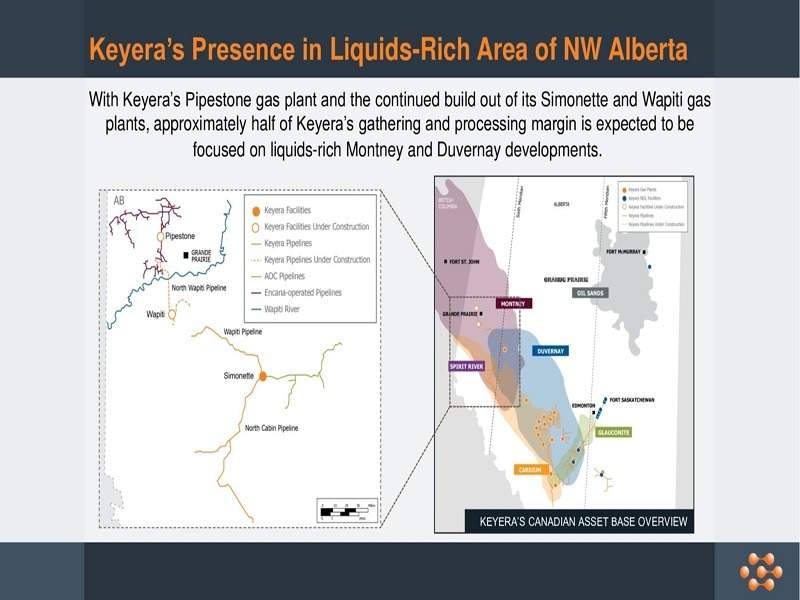

The Pipestone natural gas processing facility is being built in Alberta, Canada. The project was originally developed by Encana, a North American energy producer.

Encana entered an agreement with Keyera, a Canada-based midstream business and energy company, to acquire and fund the Pipestone liquids hub and the planned processing facility in April 2018.

Keyera will own 99.9% interest in the facility, while Encana will own the remaining 0.1% interest. Encana will be responsible for the design, construction, and operation of the facility, while Keyera will be responsible for commercial development. The agreement includes an option for Keyera to gain full ownership of the project after five years of start-up.

The preliminary stage capital investment for the project is estimated to range from $500m to $600m. The construction of the facility was started in 2018, with operations expected to be commenced in 2021.

Pipestone natural gas processing facility location details

The Pipestone gas processing facility is being developed approximately 45km north-west of the Grand Prairie region in Alberta, Canada.

The site is located within the Montney formation, which is a major shale gas and natural gas reserve.

Pipestone processing facility details

The Pipestone plant will be equipped with one feed and sales gas train and one compression train. It will be capable of processing approximately 200 million cubic feet (Mcf) of sour gas per day and 24,000 barrels of raw condensate per day.

The first train will consist of Siemens SGT-750 gas turbine, which will drive two Dresser-Rand DATUM centrifugal compressors along with a Siemens waste heat recovery unit to process heat. The second train for refrigeration compression will include a DATUM compressor driven by a Siemens electric motor and equipped with Siemens variable frequency drive.

The Pipestone facility will also be equipped with acid gas injection capabilities and associated water disposal facilities. A second phase of the project with a capacity of up to 200Mcf per day is also planned. It will help Keyera process gas from other facilities in the region and support the company’s growth.

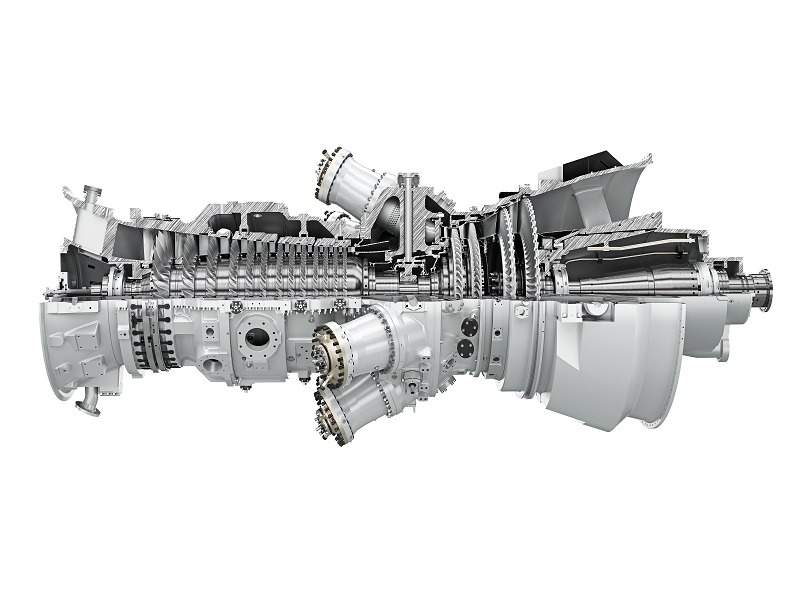

Gas turbine and compressor details

The Siemens SGT 750 industrial gas turbine consists of a core engine and a free rotating high-speed power turbine. The power generation capacity of the turbine is 39.8MW(e). The high-efficiency turbine has maximized uptime, low emissions, and small footprint.

The turbine runs on a fourth-generation dry low-emission combustion system with a two-stage free power turbine and a compressor and can designed to handle temperatures ranging from -60° C to +55° C.

The power generation frequency of the gas turbine is approximately 50/60Hz and efficiency is 40.3%. The mechanical drive of the turbine ranges from 34MW to 41MW, while efficiency ranges between 40.4% and 41.6%.

The Dresser-Rand DATUM compressors are the most highly efficient, reliable, and easy to maintain turbo-compressors used in oil, gas, and process industries.

Contractors involved

WorleyParsons was awarded the engineering, procurement, fabrication, and construction contract for the Pipestone natural gas processing facility in January 2019.

Siemens was contracted in January 2019 to supply the gas turbines and rotating equipment, while Dresser-Rand, a Siemens business, was contracted to provide the DATUM compressors.