The Prairie Lithium Brine Project is a lithium-rich brine resource which is being developed in southeastern Saskatchewan, Canada.

The project is owned 100% by Arizona Lithium (previously Hawkstone Mining), a lithium exploration and development company headquartered in Perth, Western Australia.

Arizona acquired Prairie Lithium, a privately held company, in March 2023 under a binding pre-acquisition agreement with Alberta, a wholly owned subsidiary of Arizona, signed in December 2022.

To test the Direct Lithium Extraction (DLE) technology, a pilot plant was installed at the project site. It started operations in October/November 2023.

Arizona Lithium commenced a Preliminary Feasibility Study (PFS) for the project in June 2023. It was completed in December 2023. The production drilling at the project commenced in May 2024.

As per the PFS, the construction of the first well pad of the project commenced in November 2023. The project is planned to start production from three well pads in the first half (H1) of 2025.

The total (indicated + inferred) mineral resource estimate of the project is 6.3 million tonnes (Mt) of Lithium Carbonate Equivalent (LCE).

With average annual operating costs of US$2,819 per tonne over the operating life, the project has one of the lowest costs globally.

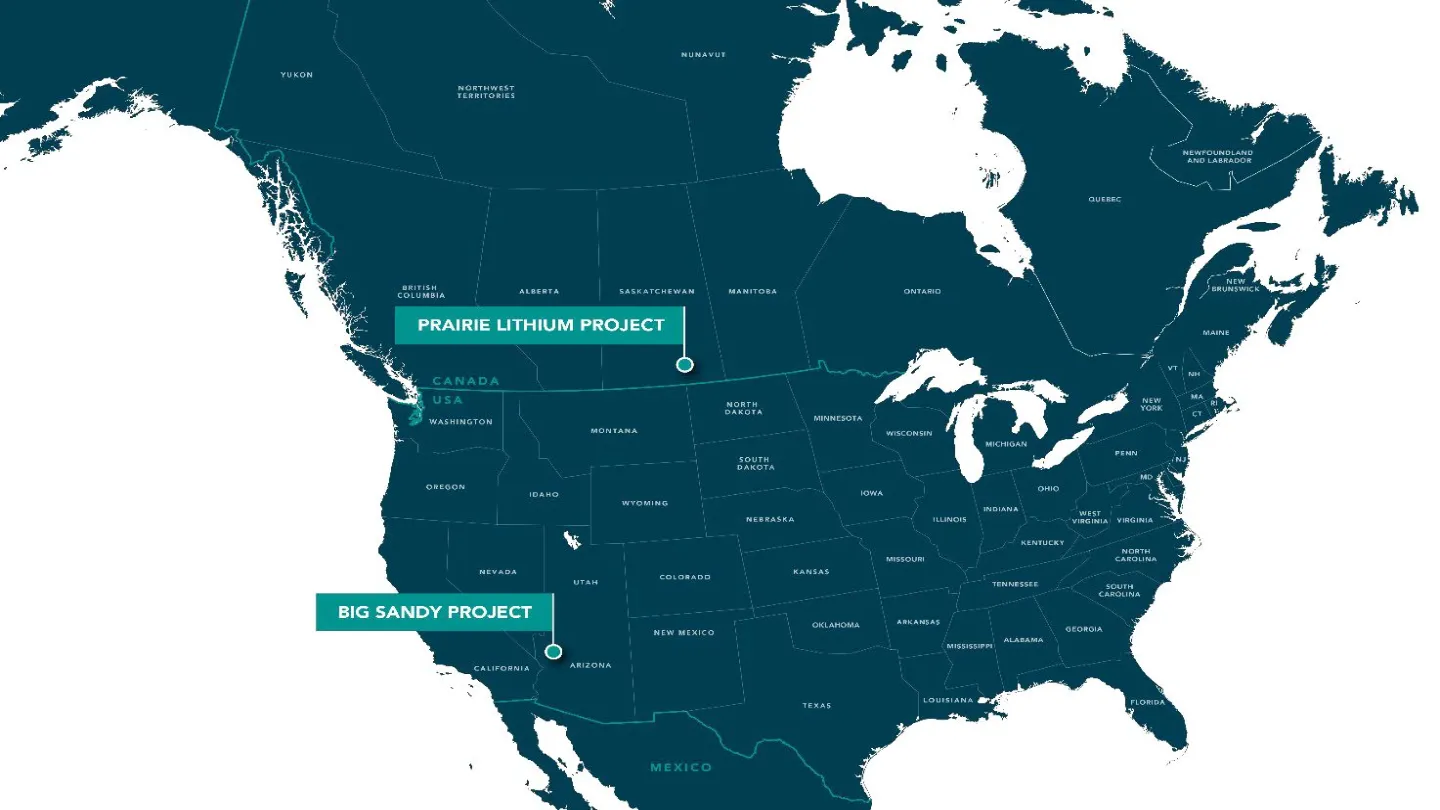

Prairie Lithium Brine Project Location

The project is located on the northeastern flank of the Williston Basin in Saskatchewan. The 560km diameter basin is an elliptically shaped intracratonic sedimentary basin located on the western shelf of the North American craton centred in North Dakota.

The Prairie Lithium Brine Project comprises over 157827.40 hectares (ha) (390,000 acres) of subsurface permits.

The project facilities are 60km south of the city of Weyburn and 40km west of the city of Estevan. Prairie Lithium Brine lies near the Canada-USA border with access to the North American road and rail network.

Highways 18, 35, and 39 cross the project site. A former Canadian Pacific Railway cuts the project site from east to west.

Geology and Mineralisation

The target interval of the Prairie Lithium Project is porous carbonate rocks of the Upper Devonian (Frasnian) Duperow Formation of the Saskatchewan Group.

The Upper Devonian sediments lie in an elongated northwest-to-southeast Elk Basin extending from northwestern Alberta to Saskatchewan, North Dakota, and Montana.

The project’s lithology is marked by layered limestone, dolomite, and evaporites. Limestone and dolomite are situated at the base. They are overlain by evaporitic intervals of halite and anhydrite.

Dolomite (carbonates) form laterally continuous aquifers of higher reservoir quality. Evaporites form poor reservoir quality intervals as vertical permeable baffles or aquitards.

Dolomite increases in thickness in the northeastern part of the project. Its thickness and occurrence decrease upwards within the Duperow Formation.

Mineral Resource Estimate

The indicated mineral resource estimate of the project is 4.5Mt of LCE containing 850,000 tonnes (t) of lithium at a grading of 106 milligram per litre (mg/L).

The inferred mineral resource estimate of the Prairie Lithium Brine Project is 1.8Mt of LCE containing 340,000t of lithium at a grading of 101mg/L.

Lithium Extraction Process

The PFS outlines a well network for the Prairie Lithium Brine Project. The network will have 13 production wells, 15 injection wells, and three brackish water source wells. These wells are divided between three well pad locations.

Conventional oil and gas drilling and completion methods are used to access lithium brine from aquifers around 2.3km underground.

Lithium-rich brine will be extracted from the process facilities at each well pad and the lithium-depleted brine will be reinjected into the subsurface.

At each well pad, the lithium-depleted brine will need on-pad disposal rates of 10,500m3 per day (m3/d) to 12,000m3/d.

Water for the operations will be produced by processing water from three brackish water source wells via reverse osmosis. The net consumption of brackish water will be between 727m3/d to 1,090m3/d.

Before using in DLE technology, water will be heated to at least 75oC through heat transfer from the depleted steam and brine.

The required brackish water rates for DLE desorption will be supplied by the Newcastle Formation and Mannville Group sandstone reservoirs.

The extracted brine is then sent to the process plant for processing.

LCE Recovery Details

The extracted brine is filtered in a processing plant to remove suspended solids. It is then pumped to the DLE system. The system concentrates lithium and removes sodium, magnesium, calcium, and potassium.

The depleted brine is used to preheat the DLE strip solution before reinjection via a disposal well system of each well pad.

The concentrated lithium is transported to a softening and concentration package. The resulting effluent is clarified and filtered along with removing precipitated solids.

The effluent undergoes softening again in a weak acid cation exchange (WAC IX) skid. The produced brine is sent to the Gradient Reverse Osmosis Infinity (ROI) system.

In the ROI system, lithium chloride undergoes desalination and concentration (around 16 times feed concentration).

After heating, the produced lithium chloride is transferred to a lithium carbonate crystallisation reactor and then contacted with a soda ash solution.

In the crystalliser, lithium carbonate (Li2CO3) is precipitated. It is dewatered and dried, producing over 99% by weight of lithium carbonate to be sold into the market.

Prairie Lithium Brine Project Infrastructure

The infrastructure of Prairie Lithium Brine consists of a network of roads and transmission lines.

The power to the project will be delivered by SaskPower transmission and/or distribution lines running across the project. SaskEnergy will supply natural gas.

For bulk storage of reagents, central headquarters will be developed in Estevan or Weyburn. The well pads will have truck access to unload reagents and loading products for the market.

Prairie Lithium Brine Project Contractors

The PFS for the Prairie Lithium Brine Project was prepared by Samuel Engineering, a global engineering group.

iLiAD Technologies, a subsidiary of Energy Source Minerals and DLE technology provider, developed the DLE system for the project.

For the drilling program, Rhythm Engineering, engineering company based in Calgary, Alberta, was awarded the the Drilling and Completion Engineering and Supervision Services in February 2024.

Financing

Under the Saskatchewan Government’s Oil & Gas Processing Investment Incentive Program (OGPII), the project was financed by up to $21.6m.

The project raised $10m (before costs) via a placement to institutional and investors in July 2023.