The Prieska copper-zinc project located in Kimberley, Northern Cape Province, South Africa, is being developed by Orion Minerals with an estimated investment of $282m.

Scoping study of the project was completed in December 2018 and the bankable feasibility study (BFS) is expected to be completed by the second quarter of 2019. Construction of the project is expected to be commenced by the third quarter of 2019.

Prieska mine is expected to produce between 70,000 tonnes (t) and 80,000t of zinc and 22,000t of copper in concentrates per annum, through its initial (first phase) mine life of ten years.

Prieska copper-zinc project location, geology, and mineralization

The historic mine was operated by Prieska Copper Mine (PCM), a subsidiary of Anglo-Transvaal, from 1971 until closure in 1991.

Project Gallery

-

Prieska project is expected to produce up to 80,000t of zinc and 22,000t of copper in concentrates per annum. Image courtesy of Orion Minerals.

-

The Prieska copper-zinc project is located in the south-west region of Kimberley in the Northern Cape Province. Image courtesy of Orion Minerals.

-

The underground project will be operated at a rate of 2.4Mtpa. Image courtesy of Orion Minerals.

Prieska consists of a volcanogenic massive sulphide (VMS) body hosted by the Copperton Formation of the Areachap Group. The region also hosts multiple deposits such as Areachap, Boks Puts, and Kantien Pan.

Smouspan gneiss member, Prieska copper mines assemblage (PCMA), and vogelstruisbult gneiss member group form the core structural sequence of Prieska, while PCMA is the main source of sulphide mineralization.

The mineralized zone of the deposit has a strike length of 2,400m, while the deep sulphide zone, located below the mined-out areas, has a strike length of 2,860m.

Prieska copper-zinc project reserves

The Prieska copper-zinc project is estimated to contain JORC-compliant mineral resources of 28.73Mt grading 3.8% zinc and 1.2% copper, as of January 2019.

Mining at Prieska

Longhole stoping with paste fill (LHSF) and drift-and-fill mining with paste fill methods of mining will be applied at the Prieska project. LHSF will be mostly used in the steeper sections of the mining area, while the flatter dipping areas will be mined using drift-and-fill method.

LHSF is proposed to be applied in both transverse and longitudinal directions, based on the shape and width of the mineralized area. Major mining fleet will include seven load-haul dump units, nine 40t underground trucks, four bolters, and ten drill rigs.

Ore processing at Prieska copper-zinc project

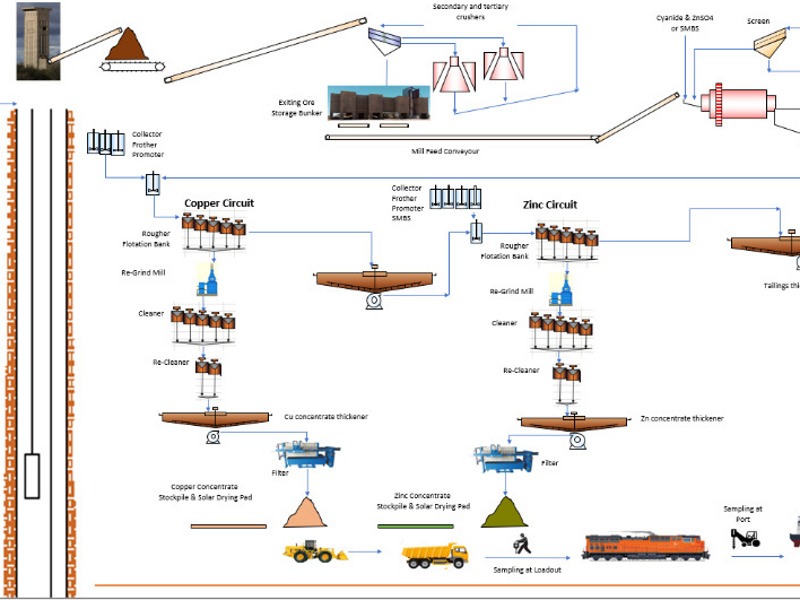

Ore will be initially crushed underground at the existing crusher chamber before being conveyed to two skip-loading flask conveyors through vibrating feeders.

At the 2.4Mtpa processing plant, ore will undergo two stages of crushing - primary and secondary. The crushed material will be screened and milled before being forwarded to rougher flotation. The concentrate from the flotation will be re-ground to achieve a cleaner flotation concentrate, which will be further cleaned to produce copper concentrate.

Zinc concentrate will be produced from the copper rougher tailings, which will undergo rougher flotation stage to produce a low-grade concentrate. The concentrate will be further re-ground and the resultant product cleaned and passed through a flotation stage to produce zinc concentrate.

The final concentrates will be loaded in tipper trucks or shipping containers to be transported either to Groveput, Prieska, or Kimberley railheads. The concentrates will be loaded onto shipping containers and transported further to the Coega Port for export.

Financing

Orion Minerals has secured a $6m bridge loan from Tembo Capital Mining Fund II for developing the Prieska zinc-copper project, in May 2018.

Prieska copper-zinc project infrastructure

The project can be accessed by the R357 regional highway from the town of Prieska. A new access road will be constructed from the existing sealed road to Copperton and the project site.

Power supply for the mine will be secured from the national grid at the Cuprum substation owned by Eskom. Power will also be sourced from a new 33MW renewable energy source.

Water will be sourced from the Orange River through Prieska Water Works and existing 450mm pipeline.

A mine village is proposed to be constructed at Copperton or Prieska to accommodate the workers.

Contractors involved

Orion prepared the scoping study of the project, with support from DRA Projects, Fraser McGill METC Engineering, Precision Capital Development Services, and Bluhm Burton Engineering.

Other parties involved in preparing the scoping study were METS South Africa, ABS Africa, Z* Star Mineral Resource Consultants, and MSA Group.

Knight Piesold Consulting designed the new tailings storage facility (TSF) for the Prieska copper-zinc project.