The Roughrider Project is a conventional uranium project in northern Saskatchewan, Canada. The project, currently in exploration stage, is fully owned by US-based uranium production and exploration company Uranium Energy Corp (UEC).

In November 2024, the company filed an initial assessment technical report summary. It included an economic analysis and mineral resource estimate.

It estimates that Roughrider Project can produce 61.2 million pounds of U3O8 over nine years.

The initial capital expenditure, including the mill and underground mine, is estimated at $545m.

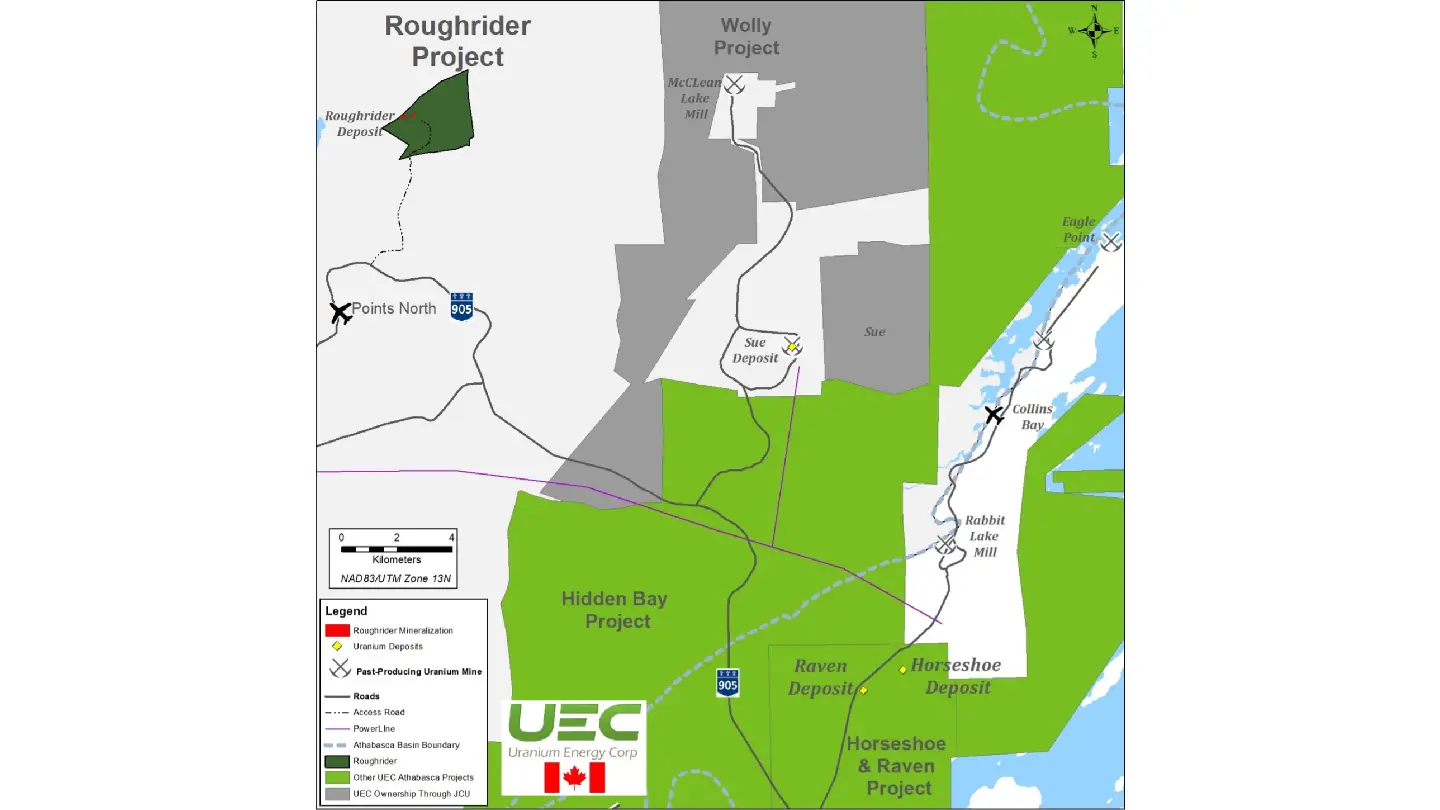

Roughrider Project Location

The Roughrider Project is located in the eastern Athabasca Basin of northern Saskatchewan. The site is around 7km of Points North Landing, a regional service centre on Provincial Highway 905.

The Exploration Stage Property is within the UEC-owned 597-hectare mineral lease ML-5547,

Background

The uranium project comprises the Roughrider West Zone (RRW), the Roughrider East Zone (RRE) and Roughrider Far East Zone (RRFE) unconformity-related uranium deposits.

Hathor Exploration discovered the deposits in February 2008, September 2009 and February 2011, respectively. Further exploration and detailed studies continued until 2016.

The uranium project was the flagship property of Hathor Exploration. It was acquired by Rio Tinto Canada Uranium Corp. (RTCU) in 2011.

In October 2022, UEC acquired 100% of the project from the Rio Tinto subsidiary for $150m, paid in cash and shares.

Subsequently, UEC launched an exploration drill programme in November 2023. As of July 2024, the company has completed drilling an additional 29,840m in 94 holes to further explore the property.

Geology and Mineralisation

The Roughrider Project is located in the Athabasca Basin—one of the world’s key uranium-producing regions.

The property comprises the Roughrider West Zone (RRW), Roughrider East Zone (RRE), and Roughrider Far East Zone (RRFE) unconformity-related uranium deposits.

These deposits occur at and beneath the unconformity between the Athabasca Group’s sandstones and conglomerates and the underlying Wollaston Group orthogneisses.

Uranium mineralisation in the area is structurally controlled, forming near and within graphitic meta-pelites. The mono-metallic mineralisation is found as stacked parallel lenses separated by intervals of barren or weakly mineralised host rock.

The primary uranium-bearing mineral is uraninite, accompanied by smaller quantities of uranophane and iron oxides displaying red to orange oxy-hydroxylisation.

Mineralisation is highly variable in thickness and style, with high grade mineralisation occurring as medium‐ to coarse‐grained, semi-massive to massive pitchblende.

Roughrider Project Mineral Resource Estimate

The Roughrider Project is estimated to hold nearly 699 kilo tonnes (kt) of indicated resources containing approximately 27.86Mlbs of uranium oxide (U3O8) at a grade of 1.81%.

Inferred resources at the property include 620kt containing approximately 33.38Mlbs of uranium oxide (U3O8) at a grade of 2.45%.

Mining and Processing

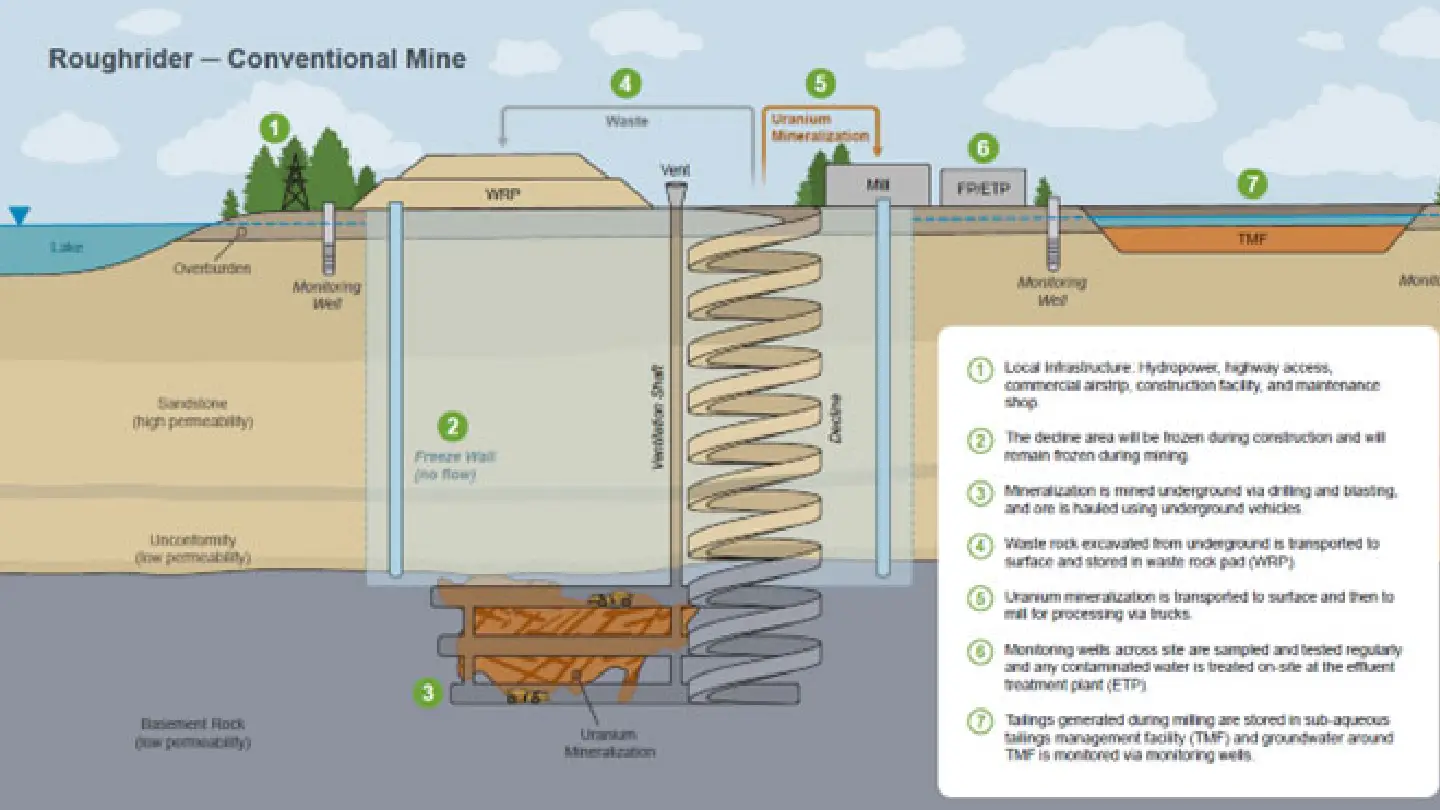

The technical report summary assumes that a decline would make the deposits accessible. All the three zones will be mined via a longhole transverse retreat mining method.

The projected mining rate is 400 tonnes per day (t/d), with extracted material hauled to surface stockpiles for processing. Cut-off grades ranging from 0.3% U₃O₈ to 0.5% U₃O₈ were evaluated, with an initial economic assessment assuming a 0.4% U₃O₈ cut-off grade.

The processing facility will be based on techniques established by other uranium operations in the Athabasca Basin, such as Rabbit Lake, Key Lake, and McClean Lake.

It is expected to operate at an average throughput of 400 t/d, with a life-of-mine (LOM) average feed grade of 2.36% U₃O₈ and a recovery rate of 97.5%.

Ore from the underground mine will be transported to the run-of-mine (ROM) pad, then it will be grounded to 250 µm in a single-stage semi-autogenous grinding (SAG) circuit.

Leaching will be carried out using sulphuric acid and hydrogen peroxide at 50°C. The resulting pregnant leach solution (PLS) will undergo counter-current decantation (CCD) and clarification.

Solvent extraction (SX) will then remove impurities while increasing uranium concentration.

Yellowcake will be precipitated from the enriched solution using hydrogen peroxide and magnesium oxide, followed by solid-liquid separation, drying at 450°C.

The product will be then packaged in barrels for shipment. Average annual production rate is expected to be 6.8 million lbs of U3O8.

Tailings and process waste solutions will be neutralised and stored in the Tailings Management Facility (TMF), while the reclaimed water will undergo treatment at a water treatment plant (WTP) and be monitored for environmental compliance before discharge.

Infrastructure

The Roughrider project site is accessible via an existing road that connects to Provincial Highway 905. All-weather access routes will be upgraded to improve connectivity, as part of the project.

The nearby Points North Landing Airstrip can be used to transport personnel and cargo.

The site will be connected to the provincial grid via a new 138kV transmission line, while backup diesel generators will be in place for emergencies.

Key mining infrastructure will comprise an underground mine with ventilation shafts, a decline for material transport, a backfill plant, and a waste rock management facility (WRMF).

The process plant area will include surface stockpiles, processing facilities, a water treatment plant, a laboratory, and essential support structures such as fuel storage and maintenance shops.

A Tailings Management Facility (TMF) will be developed to manage tailings. This will include a tailings transport system, deposition system, and a reclaim water system.

Contractors Involved

The Initial Assessment Report on the Roughrider Uranium Project was prepared by Tetra Tech Canada, Understood Mineral Resources, Terracon Geotechnique, Snowden Optiro and Clifton Engineering Group.