The proposed Runcorn CCS Project is a 0.9 million tonne (mt) carbon capture and storage plant in the UK. The project will be owned and developed by Viridor in Runcorn in the UK.

With an investment of over £0.5bn, the project will be one of the world’s first CCS projects being developed on an Energy from Waste (EfW) facility after the announcement in October 2021.

The Government of the UK shortlisted the project in August 2022 for the next stage in the Industrial Carbon Capture (ICC) sequencing process.

In March 2023, the UK Government selected the project for the final stage in the ICC sequencing process.

Moving further, Viridor signed the Statement of Principles with the Department for Energy Security and Net Zero (DESNZ) of the UK Government for the project in April 2024.

Following the final negotiations, the approval for the project development would be granted by the UK Government.

The project’s construction is expected to commence in Spring 2024 taking three to four years including commissioning by 2028.

Once operational, Runcorn CCS would deliver stable carbon dioxide supply to the HyNet Industrial Carbon Capture Cluster and support decarbonisation efforts of the UK.

The project will create 60 permanent jobs in operation and maintenance and 1,300 person-years of employment in design and construction in the UK.

Runcorn CCS Project Location

The Runcorn CCS Project will be developed at the UK’s largest Runcorn Energy Recovery Facility (ERF) around 20km from Liverpool.

The project would be developed towards the east of the Mersey River and the west of the A557 Road in Runcorn, Cheshire.

The Salt Works owned by Inovyn is located towards the west of the ERF site.

Runcorn CCS Project Details

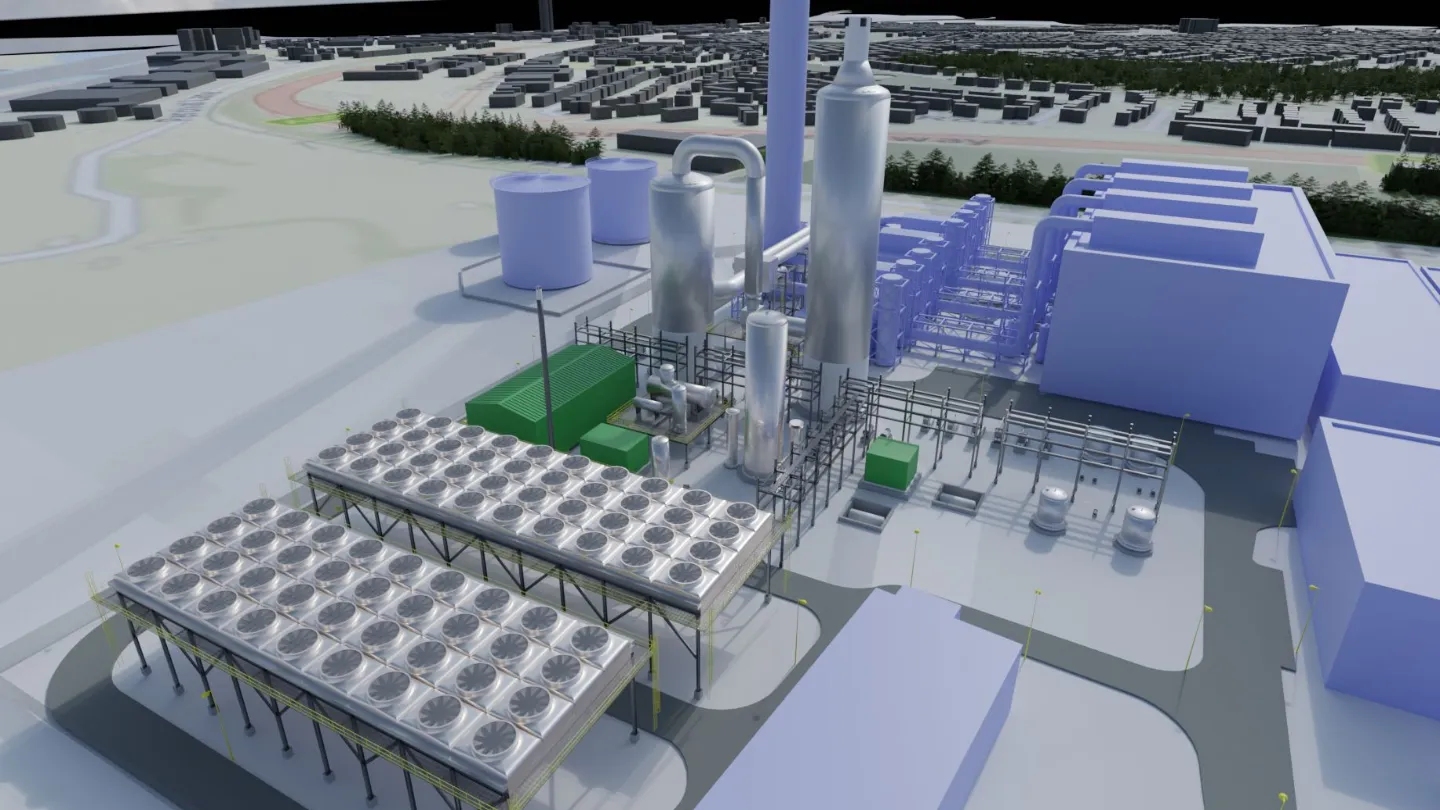

The Runcorn CCS Project will consist of a connection to the existing flue gas ducts, a Carbon Capture Technology Solution (CCTS) plant, a backpressure steam turbine, and a connection to the carbon dioxide Transportation and Storage (T&S) system at the Above Ground Installation (AGI).

From the facility, the flue gas would enter the CCS technology downstream of the induced draft fan. Four ducts of approximately 2,500mm would transport the flue gas across the cite boundary.

The CCTS plant will receive the required steam via a new backpressure steam turbine. The turbine will operate in parallel with the existing turbine.

For the decarbonised flue gas, the CCTS plant absorber would act as the new emission point. From here, the flue gas will reach the carbon dioxide T&S system.

The project will receive funding under the UK Government’s Track 1 Funding Process. Under operation, the project will capture over c.900,000 tonnes of carbon dioxide per year and remove 450,000 tonnes of carbon dioxide per year from the atmosphere.

Of the total captured carbon dioxide, half would be from biogenic sources.

CCTS Operation

The flue gas would enter the Direct Contact Cooler of the CCTS plant. Its temperature will be reduced from 140oC to 40oC and will be stacked.

The cooled flue gas will enter the absorber tower where it will react with lean amine solvent to capture carbon dioxide.

The carbon dioxide lean flue gas will pass through the heat exchanger located at the top of the absorber tower. The carbon dioxide rich solvent will be pumped to the reclaimer tower where it will be separated from the rich solvent.

The carbon dioxide stream will enter the atmosphere and the lean solvent will exit from the bottom of the reclaimer tower. The captured carbon dioxide will be conditioned, compressed, and sent to the T&S system.

The existing Energy Recovery Facility (ERF) plant will provide steam to the new CCS plant which will be used to release carbon dioxide from the rich solvent in the regeneration tower.

The power to the CCS plant will be supplied either by the existing ERF plant or upgrading the existing connection to the Combined Heat Power Plant (CHP).

Chemicals and effluents would be required for the CCTS process estimated at 130HGVs for one year.

Runcorn CCS Project Contractors

The Front-End Engineering Design (FEED) contract for the project was awarded to Technip Energies by Viridor in April 2024.

Technip will supply a comprehensive design using the Canopy by T.EN solution. The solution is powered by CANSOLV carbon dioxide capture technology of Shell.

The delivery of the Canopy is a part of Technip’s Capture.Now, a strategic Carbon Capture, Utilization and Storage (CCUS) platform of solutions and technologies.

The Owners Engineer for the plant will be Fichtner Consulting Engineers. Viridor selected Fichtner in April 2024. Fichtner will support the FEED studies with its supervision and quality assurance services.

Both the FEED and Owners Engineer contracts will entail over £20m by Viridor to progress the project to the next development stage.

Savills plc prepared the 2023 Environmental Impact Assessment (EIA) Scoping Report of the project.

Viridor selected Turner and Townsend as the Project Management Consultant (PMC) for the project in February 2022.

Under the contract, Turner and Townsend will ensure capital delivery, project management, and procurement services.

Since 2022, COWI has been acting as the Owners Engineer for the project. COWI is developing the design, timelines, and risk register of the plant besides reviewing cost and specifications from vendors for the plant installation.

For the Pre-FEED study of the project, Viridor engaged Aker Carbon Capture as the partner in December 2022. Both companies signed the Memorandum of Understanding (MoU) in 2021.

The Pre-FEED study explores the project installation in the HyNet Cluster.