The Rydberg Project is a deepwater oil, gas, and water field located in the US Gulf of Mexico. The field is designed to have an operational lifespan of 30 years.

Shell Offshore, a subsidiary of Shell, operates the project and holds an 80% working interest in the leases where the field is situated. The remaining 20% stake is owned by China National Offshore Oil Corporation (CNOOC), a state-owned oil and gas company in China.

The Final Investment Decision for the project was made in 2023. Offshore construction of the production system began between the third and fourth quarters of 2023. Production from the field officially started in February 2024.

With a peak production capacity of up to 16,000 barrels of oil equivalent per day of oil, the Rydberg Project will increase production at Appomattox in the Norphlet Corridor.

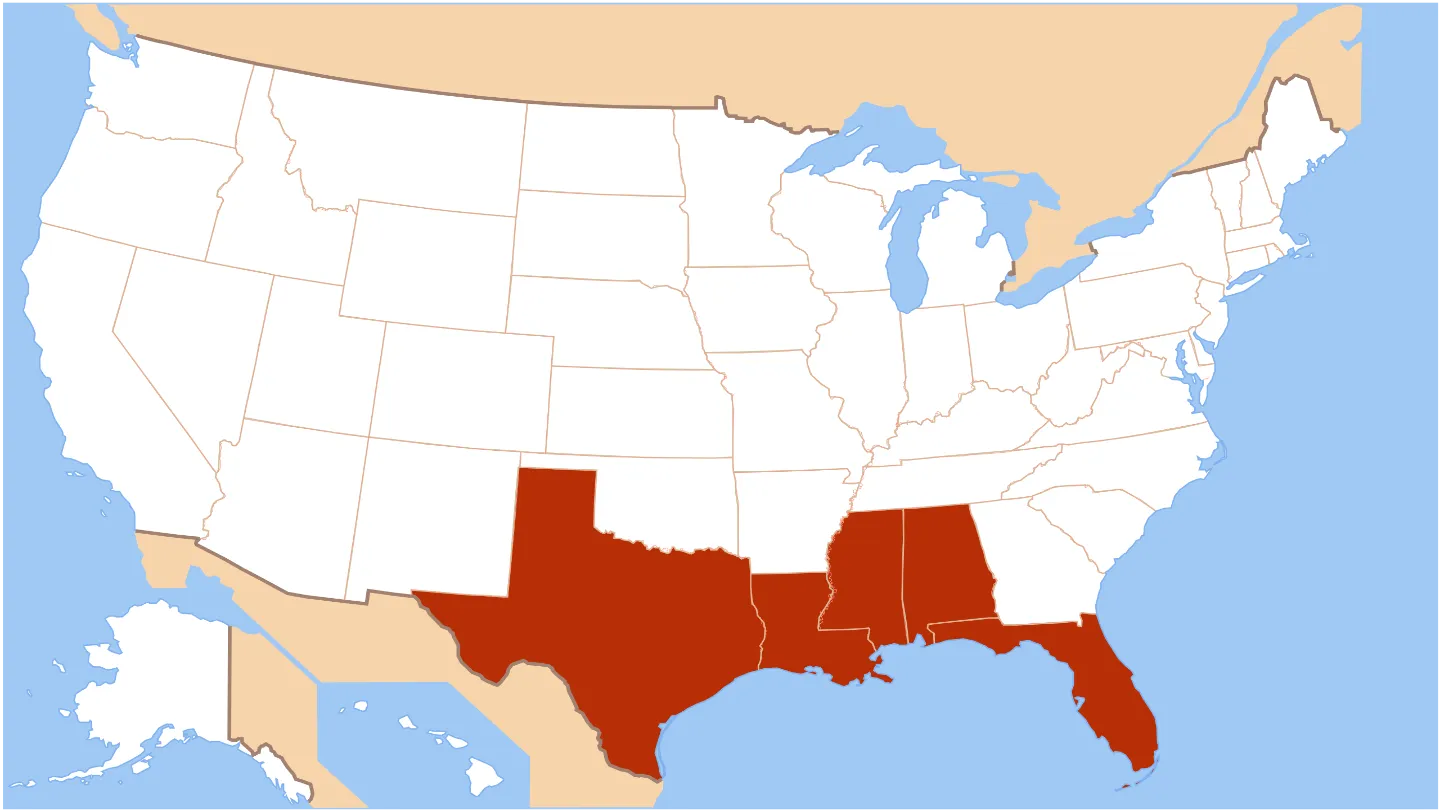

Rydberg Project Location

The Rydberg Project is situated in the Norphlet Corridor within the Mississippi Canyon (MC) area of the US Gulf of Mexico.

The field is located approximately 120.7km (75 miles) off the coast of Louisiana at a water depth of about 2,270.8m (7,450ft).

The Rydberg drill centre spans MC Blocks 525 and 569 and is positioned about 19.3km (12 miles) from the Vicksburg drill centre in MC Block 393.

Additionally, it is located approximately 16.1km (10 miles) from the Appomattox platform in MC Block 437.

Geological Details

The Gulf of Mexico is a semi-enclosed basin that has been primarily shaped by sediments from the Mississippi River since the Late Jurassic period.

To date, the basin has accumulated over 14.48km (nine miles) of Mesozoic and Cenozoic sediments.

The Gulf’s shelf sequence is composed of alternating layers of coastal plain, estuarine, deltaic, and marine sediments, forming a prograde shelf environment.

Additionally, the northern edge of the Gulf has experienced significant sediment deposition during the Tertiary and Quaternary periods, resulting in particularly thick sediment layers in these areas.

Rydbergy Project Details

The Rydberg Project comprises two well drill centres and a 19.31km (12 miles) production flowline system directly connected to a designated slot on the existing Vicksburg manifold. The field operates as a subsea tie-back to the Appomattox platform, integrating its production infrastructure into the larger network.

The drill centre includes two subsea wells, two production well jumpers, a production flowline and manifold, one Production Pipeline End Termination (PLET), and a flowline jumper. These components collectively facilitate the efficient extraction and transportation of resources from the reservoir.

The flowline system is designed to handle a maximum internal pressure of 12,200 pounds per square inch absolute (psia). It consists of five main segments: a flowline jumper, a production flowline, two production well jumpers, and one dynamic umbilical.

The oil flowline, with an outer diameter of 0.2m (8.625 inches), transports production from the wells to the Phase 1 drill centre and further to the Appomattox platform.

A total of 16 super duplex dynamic umbilical tubes, each with an outer diameter of 202.3mm, connect the Appomattox platform to the subsea Umbilical Termination Assembly (UTA).

These umbilicals are essential for delivering chemicals, electrical and hydraulic power, and communications to the drill centre. The umbilical route diameter measures 0.2159m (8.5 inches).

To ensure the longevity of the flowlines, extensive protection measures are employed. External protection includes a 63mm thick coating and cathodic protection, while internal protection relies on corrosion inhibition, material allowance, and cladding. These measures minimize wear and extend the operational lifespan of the infrastructure.

The field primarily produces oil, along with smaller quantities of gas and water, with an anticipated maximum flow rate of 25 kilolitres per day (kblpd).

This production is transported efficiently via the interconnected flowline and umbilical systems to the Appomattox platform for further processing and distribution.

The estimated recoverable resource volumes from the Rydberg field are approximately 38 million barrels of oil equivalent (mboe). These reserves are classified as 2P (proven + probable) under the Society of Petroleum Engineers’ Resource Classification System.

Rydberg Project Contractors

In September 2022, Shell, in collaboration with TechnipFMC, an engineering and construction company based in Paris, prepared the complete layout of the Rydberg Project field, including flowlines and umbilicals.

Shell also engaged Oceaneering International (OII), a subsea engineering company based in the US, to conduct a deepwater Autonomous Underwater Vehicle (AUV) Archaeological and Geohazard Assessment in September 2022.

Oceaneering used the M/V Ocean Project vessel for the AUV-based assessment.

Additionally, Fugro Geoservices (FGSI), a Dutch geotechnical services provider, was contracted to conduct surveys in the area. These surveys were carried out using the R/V Fugro Enterprise vessel to further assess the seabed conditions and geohazards relevant to the field development.