The SABIC Fujian Petrochemical Complex is an ethylene production facility that is being developed in the Gulei Petrochemical Industrial Park in the Fujian Province of China.

The Gulei Petrochemical Industrial Park is one of the seven national petrochemical hubs in China. It will be the largest single investment joint venture project between Saudi Arabia and China with the foreign investment in Fujian Province till now.

Known as the Sino-Saudi Gulei Ethylene Complex Project, the complex is owned and is being developed by SABIC Fujian Petrochemicals, a joint venture between SABIC Industrial Investment (51%) and Fujian Fuhua Gulei Petrochemical (49%) established in March 2022.

SABIC Industrial Investment is a subsidiary of SABIC, a public company headquartered in Riyadh, Saudi Arabia. SABIC is majority-owned by Aramco.

Fujian Fuhua Gulei Petrochemical is a state-owned petrochemical company headquartered in Fujian, China.

The complex is being built with an estimated investment of RMB 44.8bn ($6.4bn). The investment was approved by the Fujian Provincial Development and Reform Commission in June 2022.

The partners took the Final Investment Decision (FID) for the development of the project in January 2024.

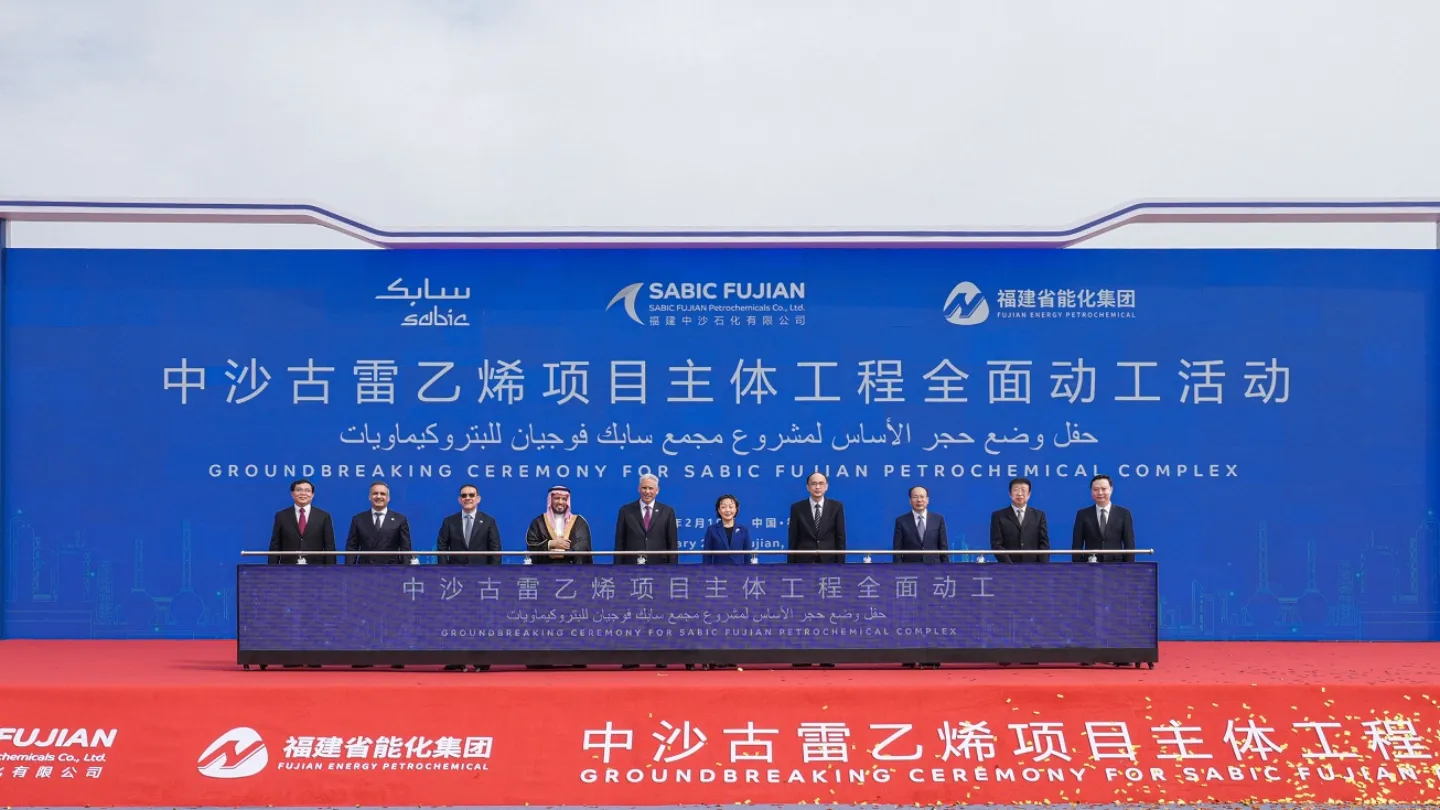

The construction of the complex commenced in February 2024 which is expected to be completed in 2026. The facility is scheduled to start commercial operations in the second half of 2026.

Once operational, the project will fulfil the market demand for high-end chemical products and stimulate downstream investment opportunities in the region.

The Sino-Saudi Gulei Ethylene Complex Project will generate a production value of about RMB 30bn ($4.27bn) per year in operations and over RMB 100bn ($14.25bn) of upstream and downstream investments.

The project will support the Belt and Road initiative of China Saudi Arabia’s vision of 2030.

SABIC Fujian Petrochemical Complex Details

The ethylene production complex will consist of a mixed feed steam cracker, downstream facilities, and other facilities, including heater equipment, and CDModules of Lummus Technology.

The mixed feed steam cracker will produce various products for the Chinese market, including Ethylene Glycol (EG), Polyethylene (PE), Polypropylene (PP), and Polycarbonate (PC).

It will be equipped with up to 1,800 kilotonnes per annum (kta) of ethylene/1,020kta of propylene Mixed Feed Steam Cracker (MFSC) unit, Benzene, Toluene, and Xylene (BTX) products, and one 60kta butene-1 unit.

The complex will have an expected ethylene production capacity of up to 1.8 million metric tonnes (mmt) per annum.

SABIC’s patented technology will be used in producing High-Density Polyethylene (HDPE) Bi-modal products, producing 400,000 tonnes of High-Density Polyethylene (HDPE) per year.

A series of downstream facilities will be installed as a part of the infrastructure of the complex.

The deployment of KBR’s phenol technology will help in reducing energy consumption and improve yields.

With the use of CTCI’s green engineering technology, the production from the project will become efficient, supporting the 2050 Net-Zero Emissions target.

SABIC Fujian Petrochemical Complex Contractors

The Engineering, Procurement, and Construction (EPC) contract for the Sino-Saudi Gulei Ethylene Complex Project has been awarded to China Petroleum Engineering (CNPC), a Chinese oil and gas corporation. The contract is valued at $1bn.

The HDPE Bi-Modal EPC contract for the petrochemical project was awarded to CTCI Beijing, a subsidiary of CTCI and an EPC services provider, in February 2024.

A global technology licensor, KBR, has been engaged as one of the contractors for the development of the petrochemical complex in China.

KBR was awarded the contract for the project in April 2022 by SABIC Fujian Petrochemicals.

As a part of the contract, KBR will provide its phenol technology license for the complex. Also, the company will deliver its proprietary engineering design for the phenol plant which is to be installed at the Sino-Saudi Gulei Ethylene Complex Project.

In March 2024, SABIC Fujian Petrochemicals selected Lummus Technology, a global process technology and energy solutions provider, for the petrochemical complex.

Under the contract, Lummus will deliver its ethylene technology license and basic design engineering for the project. Additionally, the company will supply its proprietary heating equipment and CDModules for the development of the complex.