The San Jose Lithium mining project is a brownfield project located in Extremadura, an autonomous community of Spain. The mine is located close to the town of Caceres.

It is being developed by Tecnología Extremeña Del Lito (TEL), a joint venture between Infinity Lithium (75%) and Valorzia Mineria (25%).

The project is expected to produce 525,000 tonnes per annum (tpa) of concentrate, including 16,500 tonnes per annum (tpa) of battery-grade lithium hydroxide.

It is envisaged to cost $309m (£252.82m) to develop and is estimated to have a life of mine (LOM) of 30 years including 19 years of mining.

Pre-feasibility study for the lithium mining project was published in August 2019. The project is expected to be commissioned following 20 months of construction.

It is expected to create between 80-285 jobs during the two-year construction period and more than 186 jobs during operations.

San Jose lithium project location, geology, and mineralisation

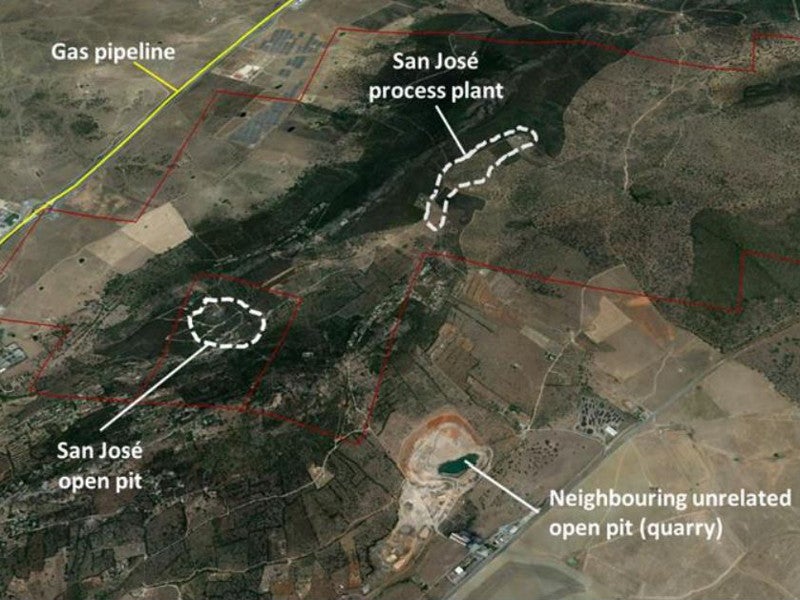

The San Jose lithium project site is located approximately 280km from Madrid and on the eastern side of Caceres.

The San Jose deposit is classified as a zinnwaldite mica replacement deposit hosted by politic slates of the Central Iberian Zone. Lithium mineralisation occurs predominantly within the slates and in minor compositions in the quartz carbonate veins.

Majority of the lithium is found in muscovite-fengite type micas of the host rock, while lesser amounts of lithium are present in amblygonite-montebrasite of the veins.

The primary mineralisation in the area appears to be lodes, stratabound or stratiform. Quartz vein or stringer systems form the lode deposits that fill late-Variscan Orogeny fractures. The lodes also carry tin and/or tungsten minerals.

The mineralisation at San Jose is pervasive and extends into the adjacent tenement area. Lower grade lithium is contained within the quartzite veins.

San Jose lithium project reserves

The probable reserves at San Jose are estimated to be 37.2Mt grading 0.29% lithium and 217ppm tin.

The indicated and inferred mineral resources are estimated to be 111.3Mt, grading 0.28% of lithium.

Mining method and ore processing

Conventional bulk-style open-pit mining, involving drilling and blasting followed by trucking and shovelling, is proposed to be used at the San Jose project.

The run of mine (ROM) ore will be transported to the processing plant located within 2km from the pit, for crushing and milling.

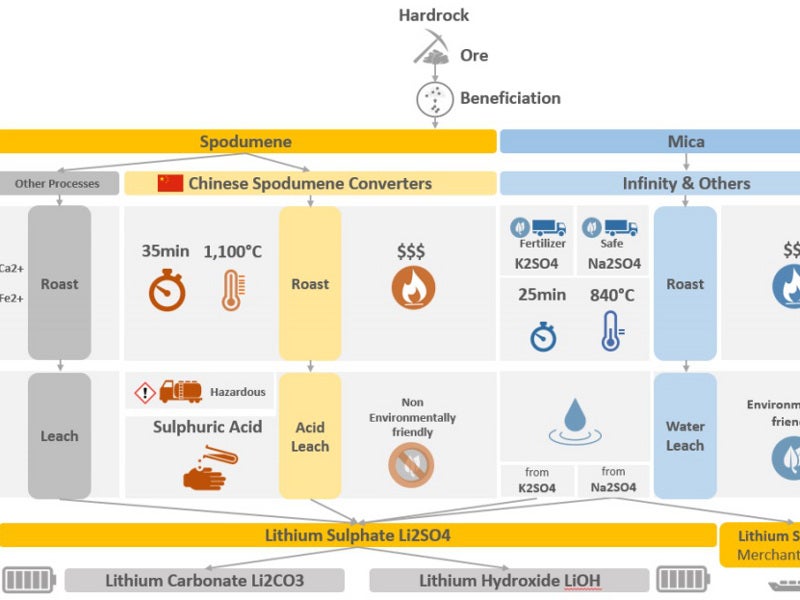

Beneficiation process using froth flotation will be used to produce lithium concentrate, which will be stored in separate dumps. Quartz rejects rich in tin will be stored separately. The beneficiation plant will produce approximately 553,000tpa of concentrate from 1.25Mtpa of ROM ore.

The lithium sulphate leachate produced will be purified and treated with hydroxide to produce lithium hydroxide. The filtered mica concentrate is mixed with potassium and fed into a kiln for roasting at a temperature of approximately 840°C.

The resultant concentrate product will be cooled and transferred to the water leach circuit to leach lithium using potable water. The process dissolves the lithium sulphates in the roasted cake allowing the leached slurry to be filtered for the removal of solid impurities such as silica.

The leachate material will be neutralised and press-filtered to remove solid particles. Caustic soda (sodium hydroxide) will be added to lithium sulphate followed by crystallisation and purification processes resulting in the production of lithium hydroxide as end product.

Infrastructure facilities

Access to the site is via a sealed road and multi-lane highways to Madrid and Merida, which are located within 3km and 6km respectively from the plant.

The project will make use of the existing supporting infrastructure nearby, such as reticulated power, water, and natural gas.

Water required by the project will be sourced from the EDAR water treatment plant in Caceres, while recycled water from tailings and recirculated process water will be used following purification.

Contractors involved

Infinity prepared the PFS for the project with the help of consultants such as Wave International (Wave), Snowden, Nagrom Laboratories, ALS Laboratories, Land and Marine Geological Services, and Mining Sense.

Infinity also engaged Cube Consulting for preparing the 2018 mineral resource estimates within the scoping study.