The Santa Cruz Copper Project is an undeveloped copper deposit located in the US state of Arizona.

Ivanhoe Electric, an American technology and mineral exploration company, holds 100% of the mineral and surface rights for the Santa Cruz Copper Project.

In September 2023, Ivanhoe announced the results from the Initial Assessment (IA) for the copper project.

The PEA outlines a potential 5.9 million tonnes (Mt) per year underground operation at Santa Cruz.

Life of Mine (LOM) copper production is estimated to be 1.6Mt over 20 years.

The company plans to submit the key permit applications in early 2025. A Pre-Feasibility Study (PFS) for the project will be delivered in the second quarter of 2025.

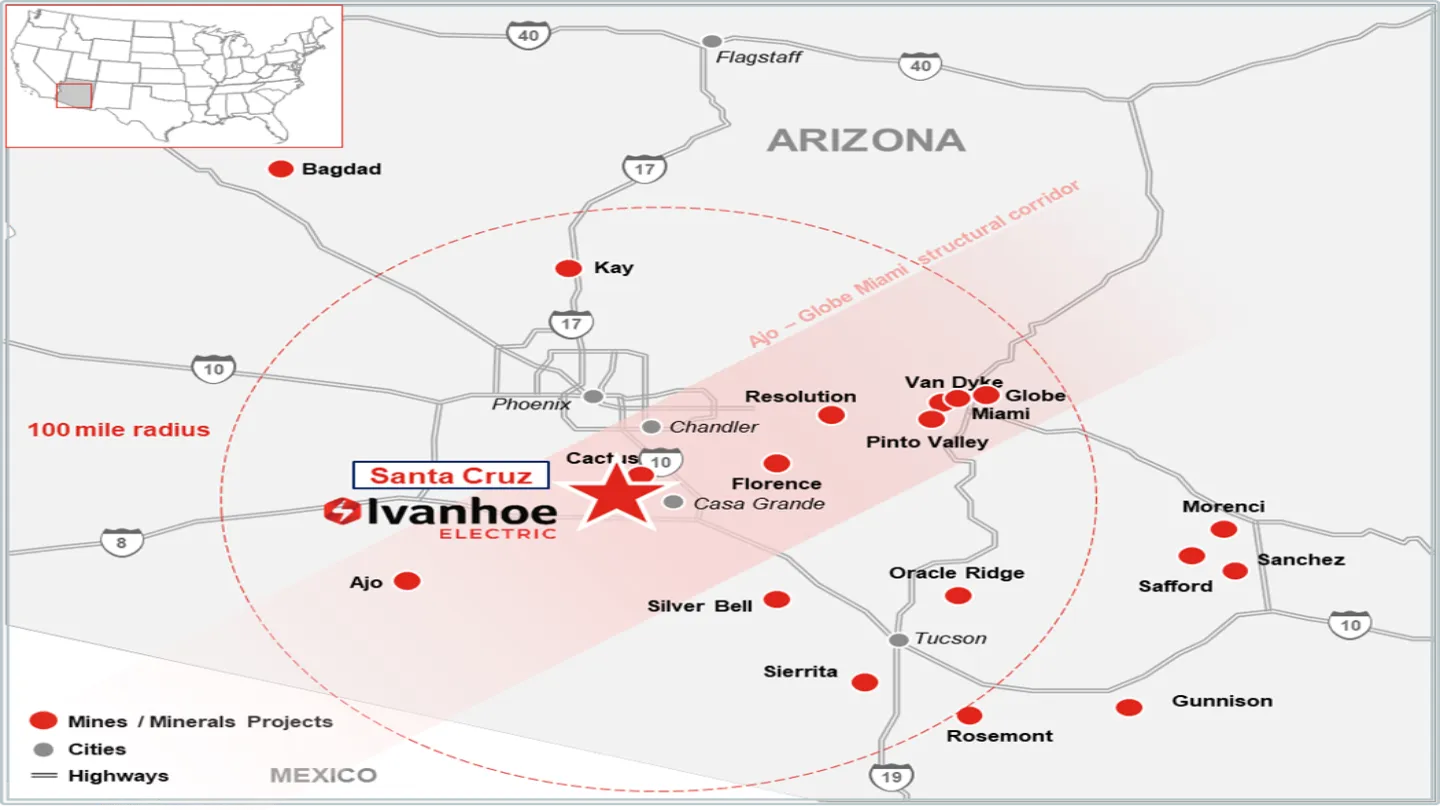

Santa Cruz Copper Project Location

The Santa Cruz project is located 11km west of the city of Casa Grande, Arizona, approximately 9km southwest of the Sacaton deposit previously mined by ASARCO, and 60km south-southwest of the greater Phoenix metropolitan area.

The project is within the Southwestern Porphyry Copper Belt and the exploration area covers 47.71km2 consisting of 25.79km2 of private land, 2.6km2 of Stockraising Homestead Act (SRHA) lands, and 238 unpatented claims or 19.32km2 of Bureau of Land Management (BLM) land.

The project is accessible from the Gila Bend highway.

Geology and Mineralisation

The copper project comprises five separate areas along a southwest-northeast corridor- Southwest Exploration area, Santa Cruz, East Ridge, Texaco Ridge Exploration area, and Texago deposits.

The deposits constitute segments of one or more extensive porphyry copper systems, which are separated by extensional Basin and Range normal faults.

The deposits are formed as a result of igneous activity during the Laramide Orogeny.

The mineralisation of the project is divided into three main groups- the primary Hypogene sulphide; the secondary Supergene sulphide; and the Supergene copper oxide mineralisation.

The primary Hypogene sulphide mineralisation consists of pyrite, chalcopyrite, and molybdenite hosted within quartz-sulphide stringers, veinlets, veins, vein breccias, breccias, and alteration.

Secondary Supergene sulphide mineralisation is primarily chalcocite forming rims around primary Hypogene sulphide.

The Supergene copper oxide mineralisation is dominated by chrysocolla (copper silicate) with subordinate dioptase, tenorite, cuprite, copper wad, native copper, and copper-bearing smectite group clays.

Santa Cruz Project Mineral Resource Estimate

The Santa Cruz Copper Project mineral resource estimate covers Santa Cruz, Texaco, and East Ridge deposits.

The total indicated mineral resource estimate for the project is 226.7Mt containing 2.8Mt copper at a grading of 1.24%, while inferred mineral resource estimate for the project is 148.9Mt containing 1.8Mt copper at a grading of 1.24%.

Mining and Recovery Methods

The Santa Cruz and East Ridge deposits were evaluated for mine planning work.

Santa Cruz will be mined using an underground Long Hole Stoping (LHS) method for the domains rich in oxide and chalcocite within the deposit.

The material will be mined in blocks from bottom to top with Paste Backfill (PBF) for support, leaving behind a sill pillar in situ between blocks.

The Exotic domain within Santa Cruz deposit is suitable for Drift and Fill (DAF) mining with cemented rock used for support.

East Ridge deposit, which is approximately 380 to 690m below the surface, will also be mined using DAF method.

The Santa Cruz mine process plant will recover copper by conventional weak sulphuric acid agitated leaching of the oxide mineralised material, and subsequent sulphide flotation of the residue.

The leached oxide copper will be processed by solvent extraction and electrowinning (SX-EW) to produce high purity copper cathodes.

Sulphide copper and by-product precious metals will be extracted through copper flotation concentrate.

The final copper concentrates will be sold to domestic or international copper smelters.

The mill process will have a nominal capacity of 5.475 million tonnes per year (Mt/y).

Project Infrastructure

The Tailings Storage Facility (TSF) will have an operational life of 23 years. It can receive a maximum of 9,800 tonnes per day (t/d) of tailings, based on annual tailings production and underground backfill requirement estimates.

Santa Cruz will have an annual power consumption of between 436,000 megawatt hours (MWh) and 473,000MWh at peak production years.

Over the LOM, the power consumption will average 211,000MWh per year.

Electrical District No.3 (ED-3), Arizona Public Service (APS), or Salt River Project (SRP) have transmission lines and substations nearby the project site. Regular grid power can be procured from any of these three suppliers.

The mining and processing operations will require approximately 3.5 million cubic meters (Mm³) of water per year, which will be sourced from the dewatering of underground operations.

Contractors Involved

The PEA for Santa Cruz was prepared by the Canadian mining consultant SRK Consulting.

The other companies involved in the preparation of PEA were KCB Consultants; Tetra Tech; Haley & Aldrich; Nordmin Engineering; Call & Nicholas; M3 Engineering and Technology; INTERA, and MET Engineering.

Sage Geosystems and KR Saline & Associates conducted studies for energy supply.

In May 2024, Fluor Enterprises, an American engineering and construction company, was selected as the principal lead for preparing the PFS. BBA USA will be responsible for Mineral Resource/Mineral Reserve and Mine Engineering.